Energy-saving and environment-friendly oil-stone separation device for road old asphalt mixture

An energy-saving and environmental protection separation device technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of low control accuracy and efficiency, temperature, solvent consumption, soaking time control requirements, and large solvent consumption, etc., to improve The effect of oil-stone separation, improving the effect of oil-stone separation, and improving the separation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

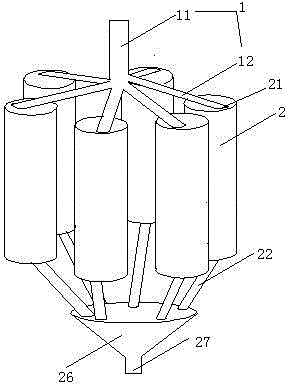

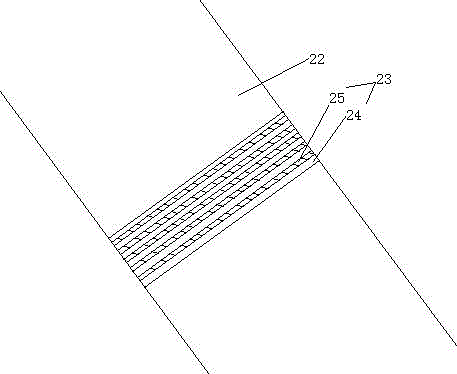

[0012] As shown in the figure, an energy-saving and environment-friendly old asphalt mixture oil stone separation device for roads, which includes a plurality of separation tanks 2 and a feeding device 1, the number of the separation tanks 2 is six, and the separation tanks 2 It is a cylinder, the separation tank 2 is evenly distributed in the circumferential direction, the top feeding port 21 of the separation tank 2, and the feeding device 1 is an integrated structure, including a feeding pipe 11 and a feeding notch 12, and the feeding pipe 11 For vertical arrangement, the feeding notch 12 is located at the bottom of the feeding pipe 11, the feeding notch 12 is an inclined pipe body, and the bottom of the feeding notch 12 is connected to the top feeding port 21 of the separation tank 2; the separation tank 2 The bottom is provided with separation pipeline 22, and described separation pipeline 22 is inclined to be arranged, and a plurality of screening devices 23 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com