Method for manufacturing aquatic plant harvesting and salvaging equipment

A manufacturing method and technology for aquatic plants, which are used in harvesters, cleaning of open water surfaces, and equipment for eliminating weeds, etc., can solve problems such as inability to remove root plants on water surfaces, damage to water ecosystems, and inability to adapt to the requirements of river clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

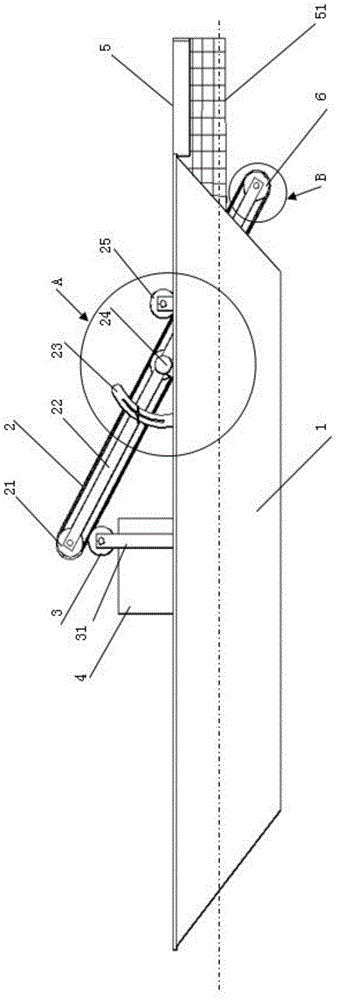

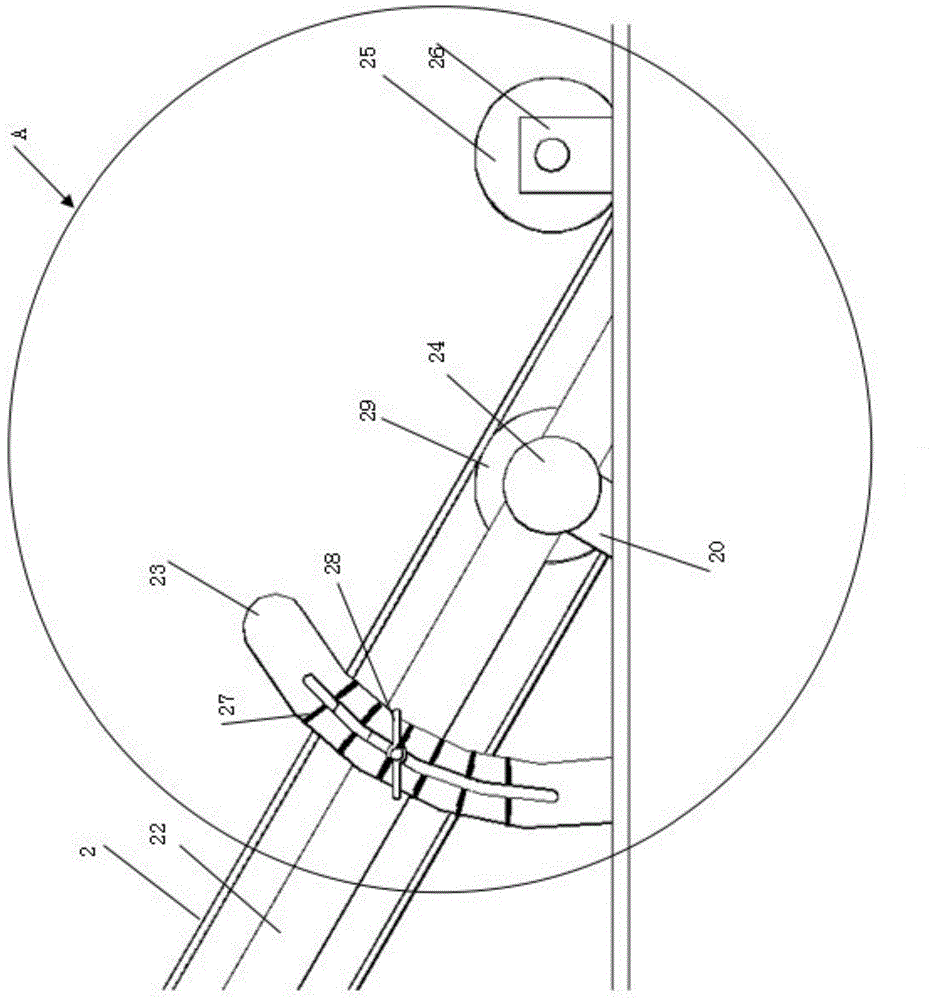

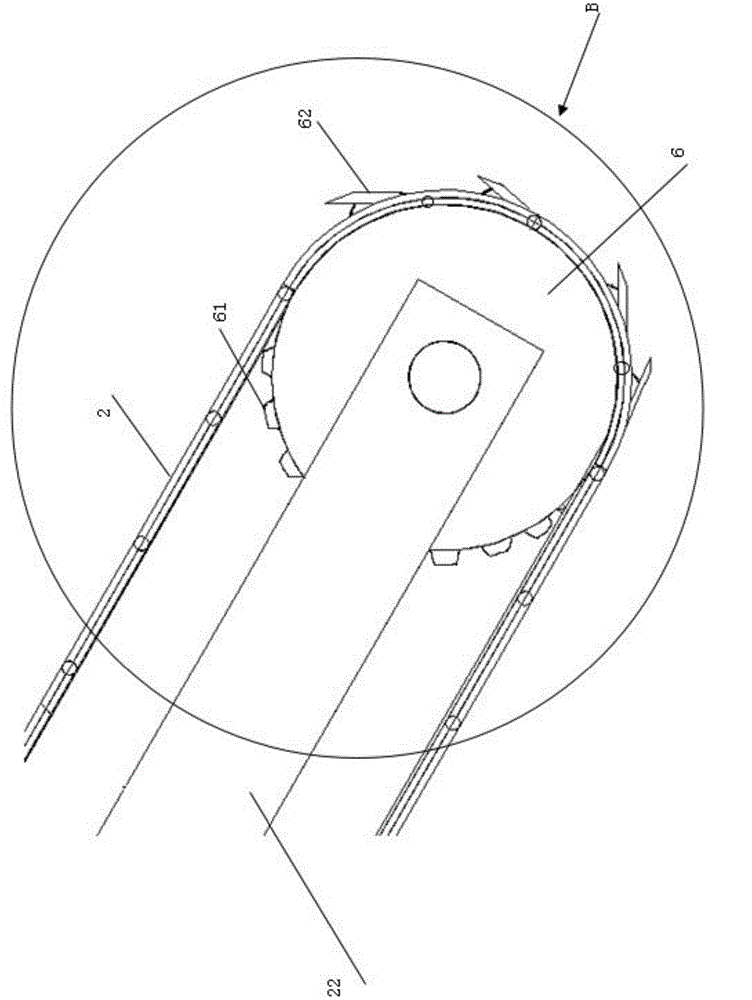

[0031] Embodiment 1: as figure 1 , 2 , shown in 3, 5, a kind of aquatic plant harvesting fishes equipment, is made of hull 1, fishes system and harvesting system, fishes system is the support 22 that is arranged on the hull 1 and the conveyer belt 2 that is located on the support 22; Harvesting system For the cutter 62 arranged on the conveyor belt 2, after the cutter 62 cuts off the plants, the conveyor belt 2 picks up and transports the plants to the hull 1. Support 22 is arranged on the both sides of the front end of hull 1, and the middle part of left and right support 22 is arranged on the vertical support 20 of hull 1 both sides with shaft activity, and the front end of left and right support 22 is provided with lower roller 6, and the middle part of left and right support 22 is provided with drive. Wheel 29, the rear end of left and right bracket 22 is provided with upper roller 21, conveyer belt 2 is arranged on lower roller 6, driving wheel 29 and upper roller 21, an...

Embodiment 2

[0032] Embodiment 2: as Figure 4 As shown, a kind of equipment for harvesting and fishing for aquatic plants, on the basis of the structure of embodiment 1, the strip cutter 62 and the pressure wheel 25 are not installed, and the rice and wheat harvesting system is set on the front side of the lower roller 6 at the front end of the bracket 22, That is, the cutting knife 7 can be swung left and right, and when the hull is running forward, the cutting knife swings left and right under the drive of power to cut / shear the stems of the plants, and the rotating conveyor belt 2 picks up and transports the plants floating on the water surface and the cut / sheared plants onto Hull 1.

[0033] The manufacturing method of the above two examples of aquatic plant harvesting and fishing equipment is characterized in that it comprises the following steps:

[0034] (1) The hull 1 is provided, and the channel steel bracket 22 is arranged on both sides of the front end of the hull 1, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com