Construction method and self-compacting concrete used for ultra-large ring structure with variable cross-section

A technology of self-compacting concrete and ring structure, which is applied in building construction, processing of building materials, sustainable waste disposal, etc. It can solve the problems of large construction area, complex and special structure, lack of concrete, etc., and achieve the goal of ensuring quality and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

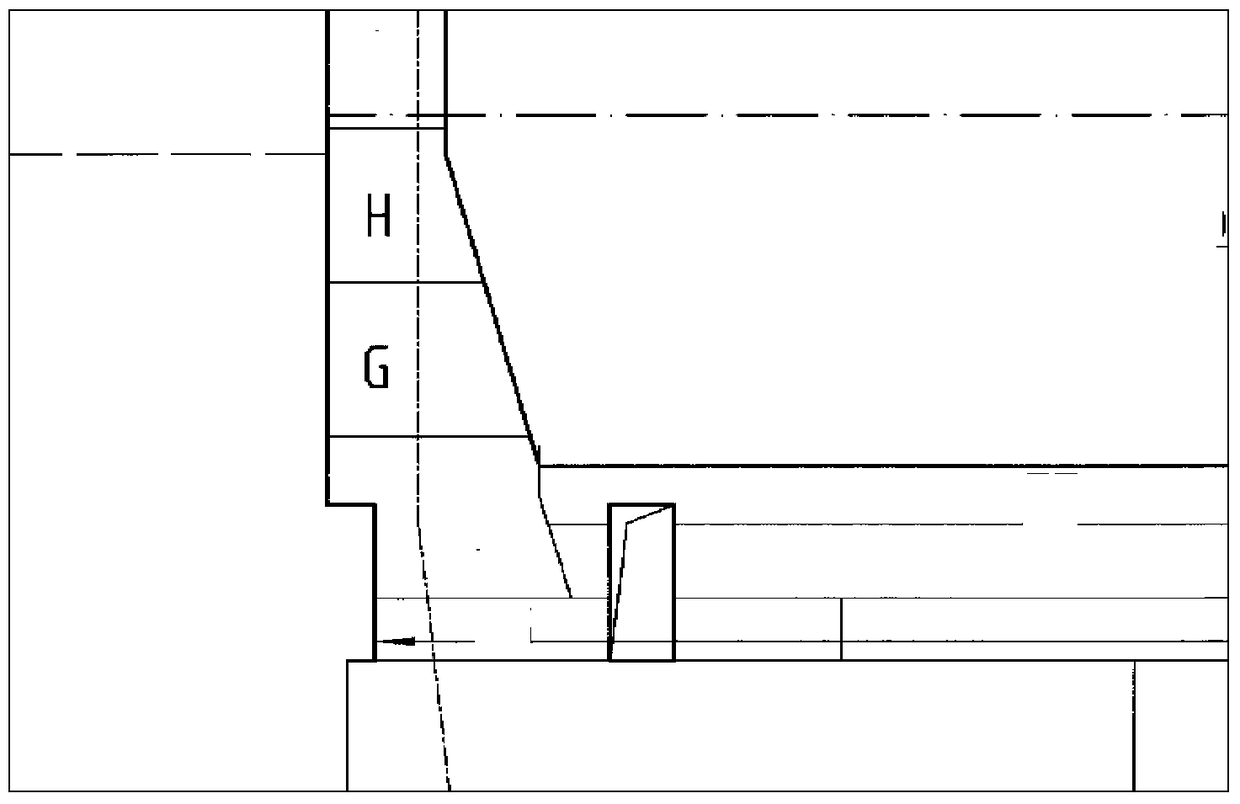

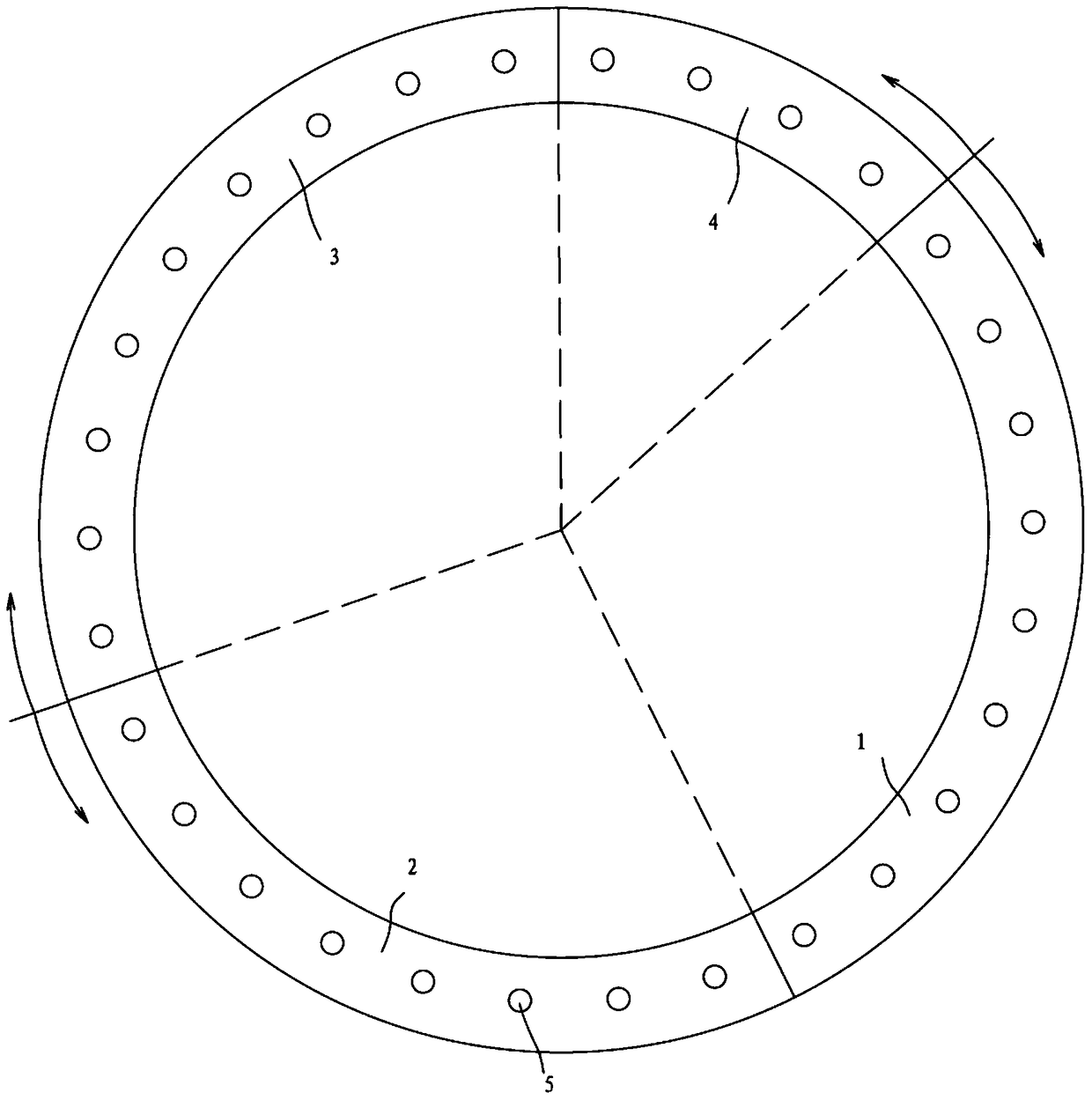

[0029] The super large ring structure in the present invention refers to a ring structure with a height exceeding 2M, an upper inner diameter greater than 15M, a lower inner diameter greater than 16M, and an outer diameter greater than 19M.

[0030] The construction method of the ultra-large annular structure with variable cross-section in the present embodiment comprises the following steps:

[0031] 1) Set pouring points at intervals of a set distance along the circumference of the main body of the super large annular structure with variable cross-section. Self-compacting concrete has good fluidity and segregation resistance within a certain flow distance, and excellent performance indicators. If the flow distance is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com