Light rolling-free abutment backfilling material and preparation method thereof

A lightweight and raw material technology, applied in ceramic products, other household utensils, applications, etc., can solve the problems of backfill material density that is difficult to meet the design requirements, difficult to roll or tamp, ground subsidence, etc., to save non-renewable land resources , good construction workability, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The light-weight non-rolling platform backfill material and its preparation method of the present invention will be described in detail below with specific examples.

[0028] 【Preparation Example】

[0029] Implementation steps

[0030] (1) The aluminum industry waste slag should undergo preliminary crushing, and the pass rate of 2cm particle size in the screening results should not be lower than 75%;

[0031] (2) adding sintering process aluminum smelting waste slag and cement into water and mixing evenly;

[0032] (3) Add polycarboxylic acid-based high-performance water reducer and sodium sulfite reducing agent, and mix well to obtain a finished lightweight mixture.

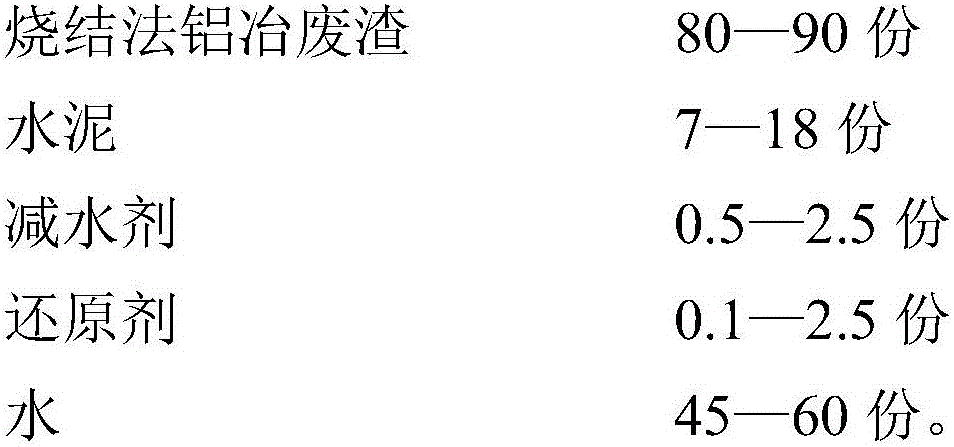

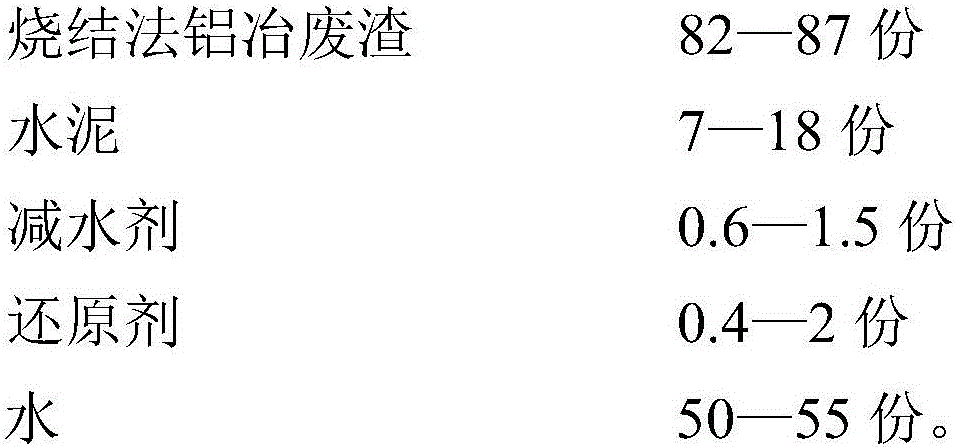

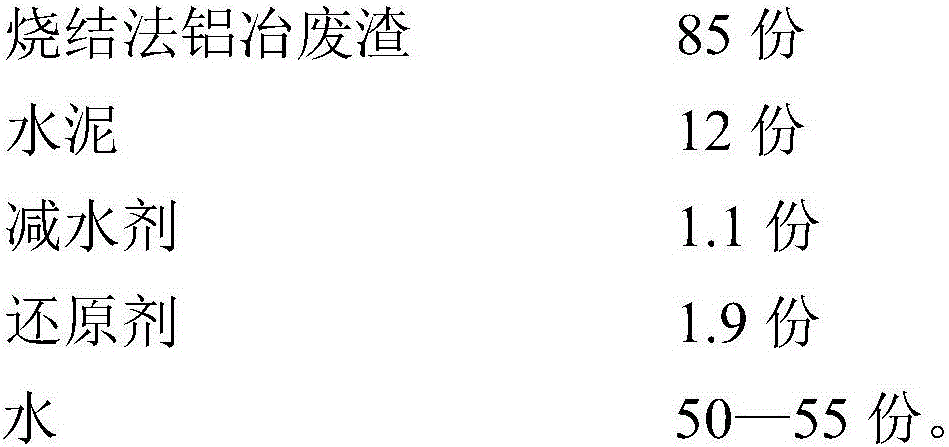

[0033] The weight ratio of each raw material:

[0034]

[0035]

[0036] 【Test method and effect】

[0037] Backfill:

[0038] The lightweight mixture (Example 1 to Example 5) prepared according to the above method was directly backfilled into the trench without vibrating and compacting.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com