A kind of pipeline engineering trench backfill material cement multi-compound mixture and preparation method

A technology of trench backfilling and pipeline engineering, which is applied in the field of building materials, can solve problems such as impact on life safety and ground subsidence, and achieve the effects of saving manpower and material resources, increasing strength and durability, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

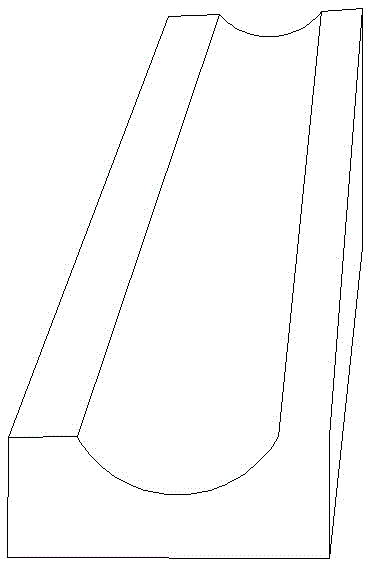

Image

Examples

Embodiment 1

[0013] The preparation method of the pipeline engineering trench backfill material cement multi-mixture of the present embodiment, its steps are:

[0014] (1) Material selection: The construction waste crushed mixture and soil are used as the main constituent materials, supplemented by a small amount of cement, and the cement accounts for 3% of the total mixture;

[0015] (2) Mixing with water: the soil accounts for 35% of the total amount of the mixture, and the plasticity index of the soil is 10. According to the plasticity index of the soil used to guide the amount of water added, the amount of water added accounts for 10% of the mixture, forming a kind of easy Good mixture;

[0016] (3) Pipeline backfill: In the construction of pipeline backfill, pour the prepared mixture directly into the backfill trench, vibrate it with a vibrating rod and smooth it.

Embodiment 2

[0018] The preparation method of the pipeline engineering trench backfill material cement multi-mixture of the present embodiment, its steps are:

[0019] (1) Material selection: The construction waste crushed mixture and soil are used as the main constituent materials, supplemented by a small amount of cement, and the cement accounts for 10% of the total mixture;

[0020] (2) Mixing with water: the soil accounts for 45% of the total amount of the mixture, and the plasticity index of the soil is 20. According to the plasticity index of the soil used to guide the amount of water added, the amount of water added accounts for 16% of the mixture, forming a kind of easy Good mixture;

[0021] (3) Pipeline backfill: In the construction of pipeline backfill, pour the prepared mixture directly into the backfill trench, vibrate it with a vibrating rod and smooth it.

Embodiment 3

[0023] The preparation method of the pipeline engineering trench backfill material cement multi-mixture of the present embodiment, its steps are:

[0024] (1) Material selection: The construction waste crushed mixture and soil are used as the main constituent materials, supplemented by a small amount of cement, and the cement accounts for 6% of the total mixture;

[0025] (2) Mixing with water: soil accounts for 40% of the total amount of the mixture, and the plasticity index of the soil is 15. According to the plasticity index of the soil used to guide the amount of water added, the amount of water added accounts for 13% of the mixture, forming a kind of easy Good mixture;

[0026] (3) Pipeline backfill: In the construction of pipeline backfill, pour the prepared mixture directly into the backfill trench, vibrate it with a vibrating rod and smooth it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com