A kind of sealing anchoring member for casing subsidy and its installation device

An installation device and casing subsidy technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of unsealable small concave-convex surface of casing inner surface, unstable sealing pressure bearing performance, etc., and achieve good shape and surface The effect of smoothness requirements, improved sealing pressure bearing capacity, and good elastic deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

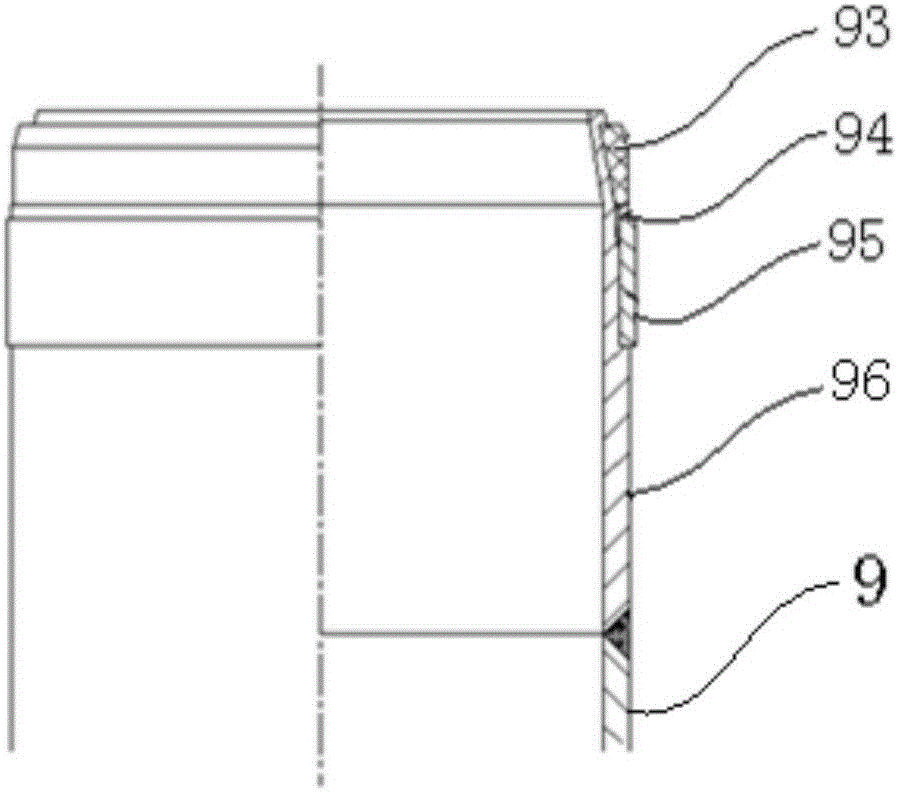

[0042] Embodiment 1: sealing and anchoring member

[0043] combine figure 1 , the sealing and anchoring member of the present embodiment comprises subsidizing pipe 9 and the anchor mechanism that is welded on two ends of subsidizing pipe, and anchor mechanism comprises first anchor mechanism 91 and second anchor mechanism 92, and first anchor mechanism 91 and the second anchor mechanism The two anchoring mechanisms 92 have the same structure, and the first anchoring mechanism 91 and the second anchoring mechanism 92 are relatively coaxially fixed at the two ends of the subsidizing pipe 9; the anchoring mechanism includes a closed metal anchor 96, a metal sealing ring 95 , the retaining ring 94, the rubber sealing ring 93 vulcanized in the groove of the mouth of the metal anchor 96;

[0044] The non-closed end of the closed metal anchor 96 is butt-welded with the subsidy pipe 9, and the retaining ring 94 at the closed end is installed on the closed metal anchor 96 by threads, ...

Embodiment 2

[0046] Embodiment 2: The installation device of the sealing and anchoring member described in Embodiment 1

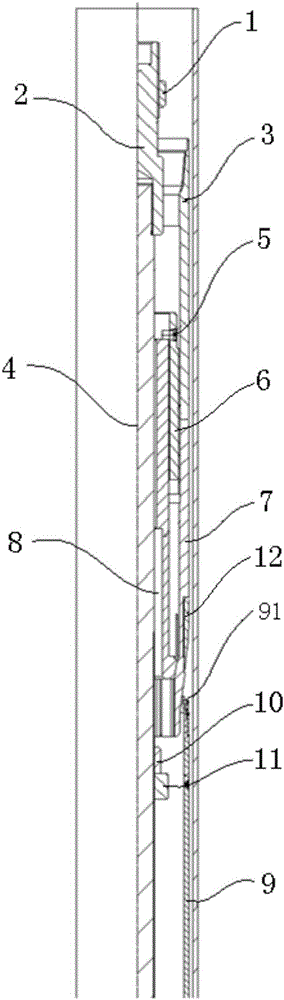

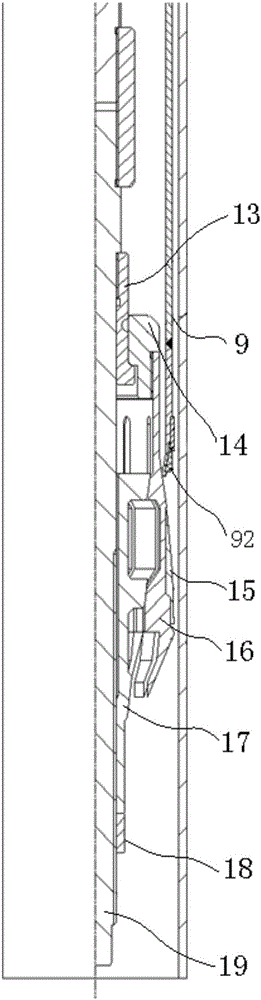

[0047] combine figure 1 , 2 , 3, 4, 5 and 6, the installation device of the present embodiment includes a power unit, a first taper sleeve installation device and a second taper sleeve installation device, wherein:

[0048] The first taper sleeve installation device includes lock pin 5, guide cone seat locking sleeve 6, guide cone 7, guide cone seat 8 and upper taper sleeve 12, the lower end of guide cone seat locking sleeve 6 fits with the upper end of guide cone 7 Fixed connection, the upper end of the guide cone seat locking sleeve 6 is provided with a lock pin 5, the lock pin 5 locks the guide cone seat 8 on the inner circumference of the guide cone seat locking sleeve 6, the guide cone seat 8 can limit the radial direction of the guide cone 7 condensation, the upper taper sleeve 12 fits on the outer periphery of the guide cone 7;

[0049] The guide cone seat 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com