Robotic leg-arm joint with full-sea deep self-balancing high-pressure sealing device

A self-balancing, high-pressure sealing technology, applied in the field of mechanical leg and arm joints, can solve problems such as reducing the reliability of the seal, increasing the weight of the substrate, and failing underwater tasks, reducing joint torque loss, low maintenance costs, and deformation. Low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

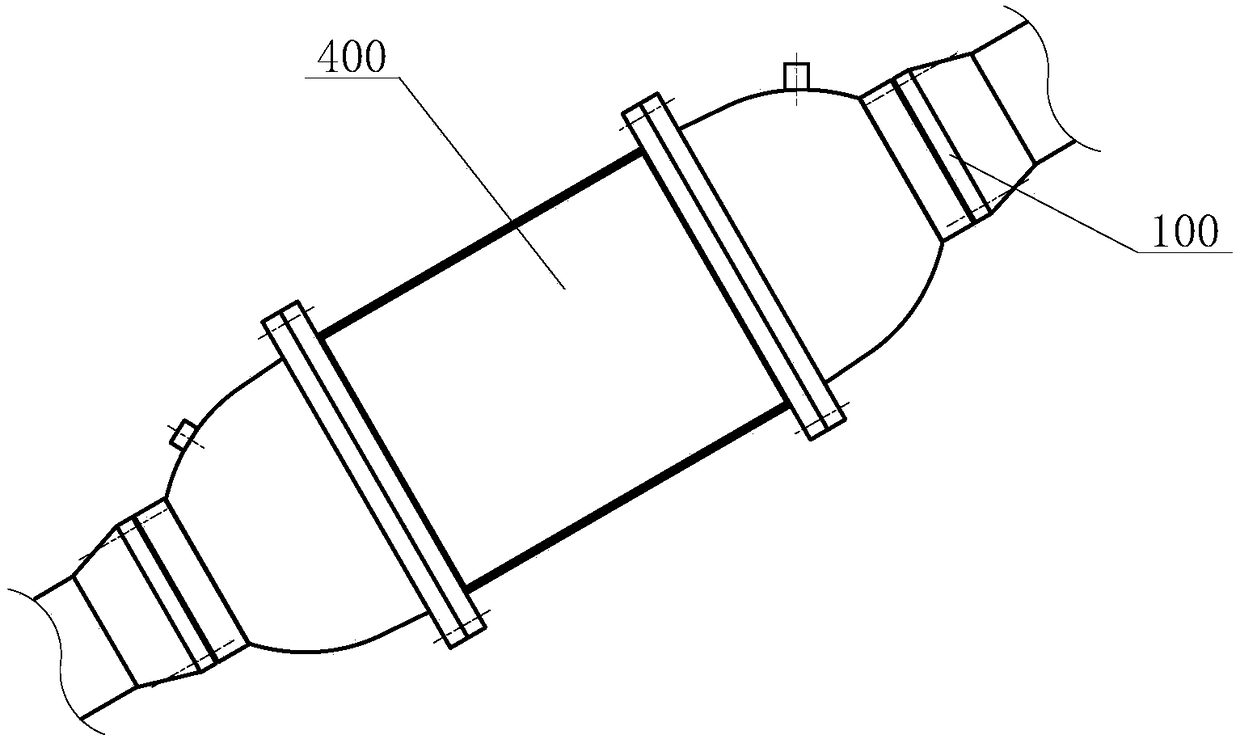

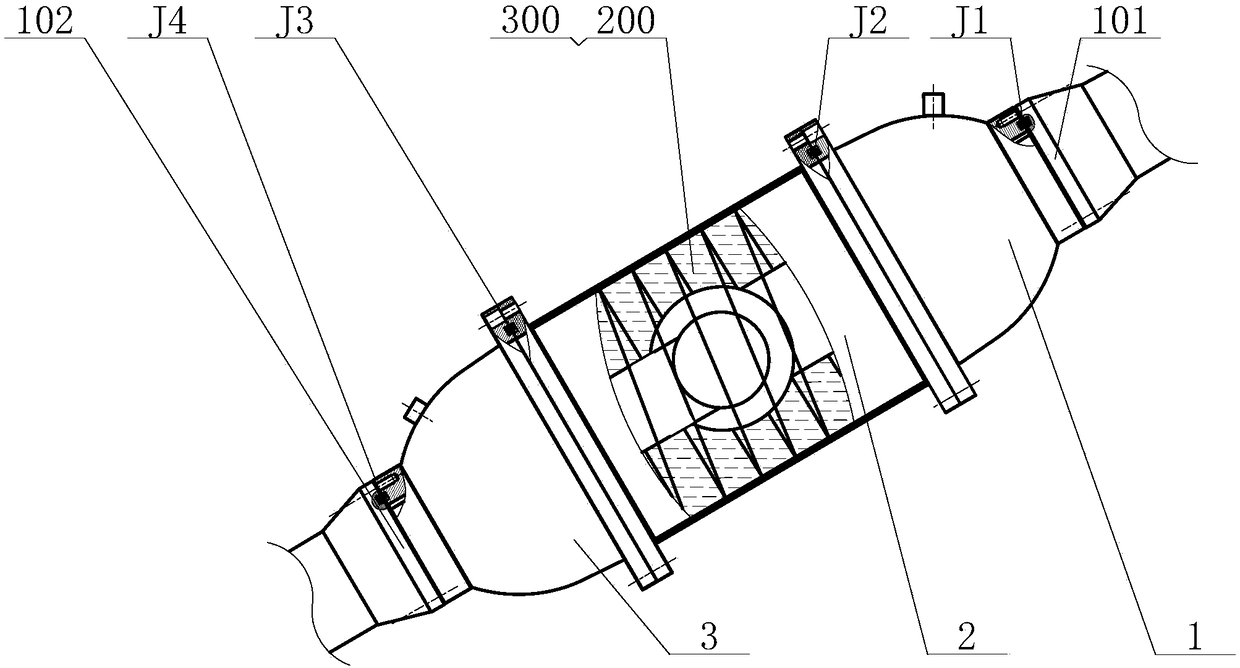

[0028] See attached figure 1 , 2 , a mechanical leg-arm joint with a full-sea deep self-balancing high-pressure sealing device, which includes: a mechanical leg-arm joint 100 and a full-sea deep self-balancing high-pressure sealing device 400;

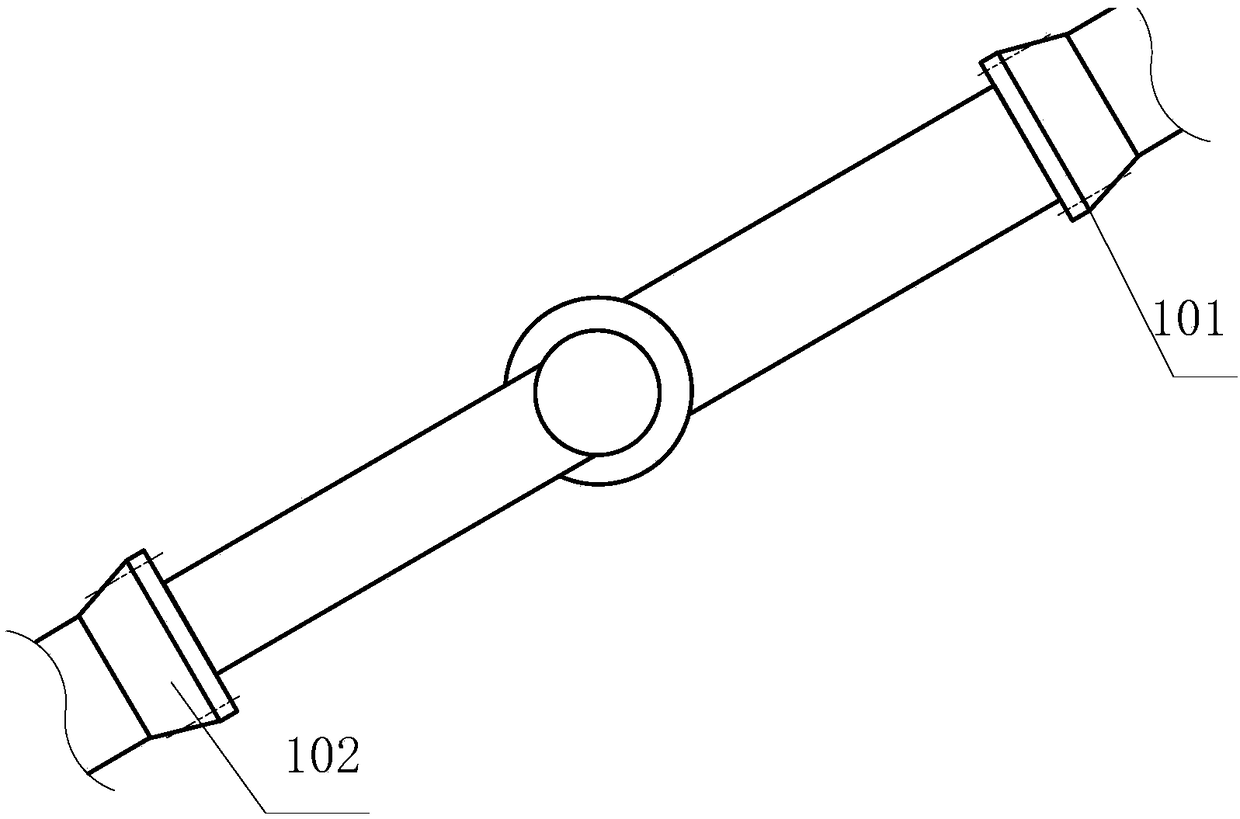

[0029] See attached image 3 , the mechanical leg-arm joint 100 is composed of an articulated upper limb 101 and a lower limb 102;

[0030] See attached Figure 4 , the full-sea deep self-balancing high-pressure sealing device 400 includes: an upper transfer bowl 1, an elastic bladder tube 2 and a lower transfer bowl 3;

[0031] See attached Figure 5 , the upper adapter bowl 1 includes: a small-diameter flange A11, a bowl body A12, and a large-diameter flange A14 connected in sequence; the exhaust valve port 13 is arranged on the bowl body A12, and the small-diameter flange A11 and the large-diameter flange A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com