Full-sea deep self-balancing high-pressure sealing device

A self-balancing, high-pressure sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of increasing the weight of the substrate, reducing the reliability of the seal, and failing underwater tasks, achieving low maintenance costs, Reduced power loss and reduced deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

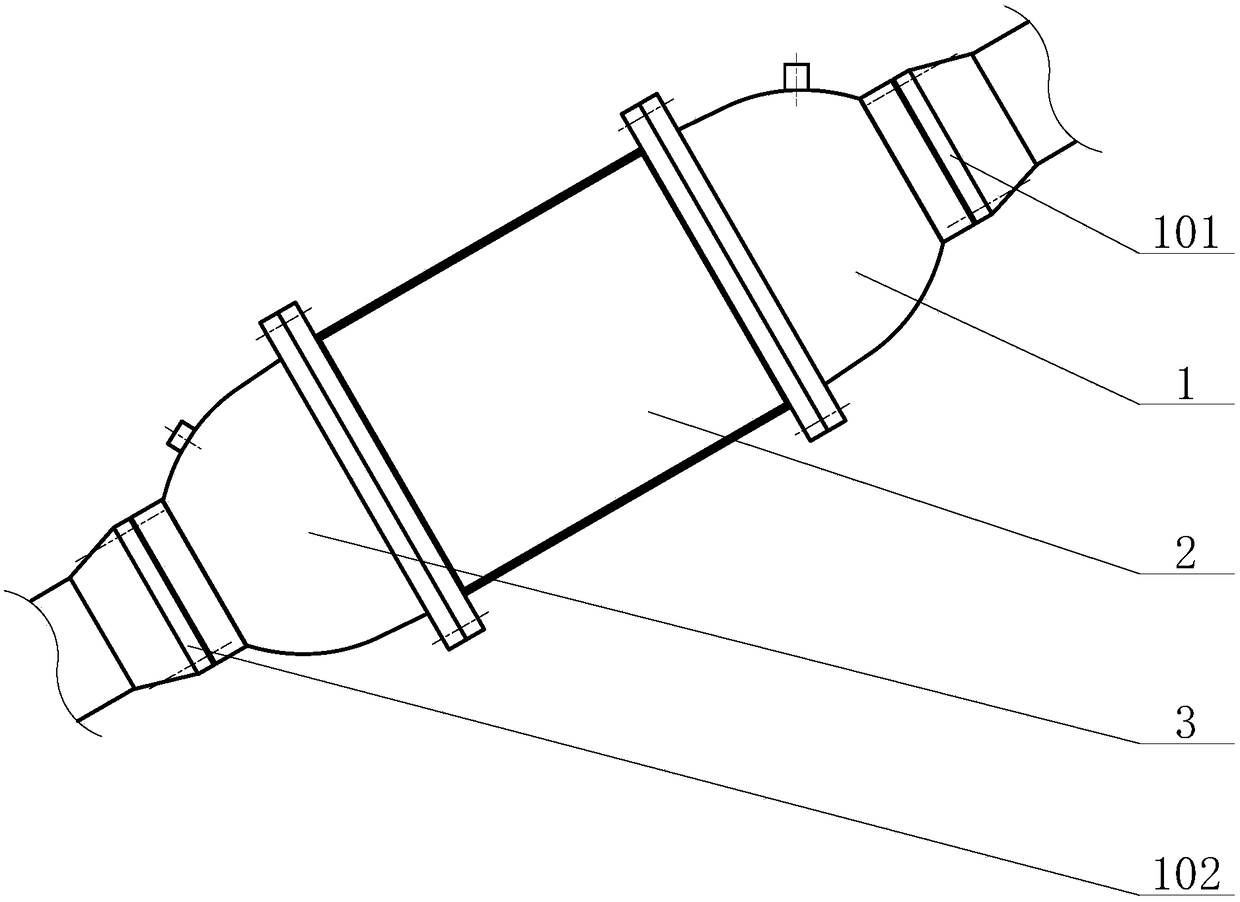

[0026] See attached figure 1 , The full-sea deep self-balancing high-pressure sealing device, which includes: an upper transfer bowl 1, an elastic bladder tube 2, and a lower transfer bowl 3.

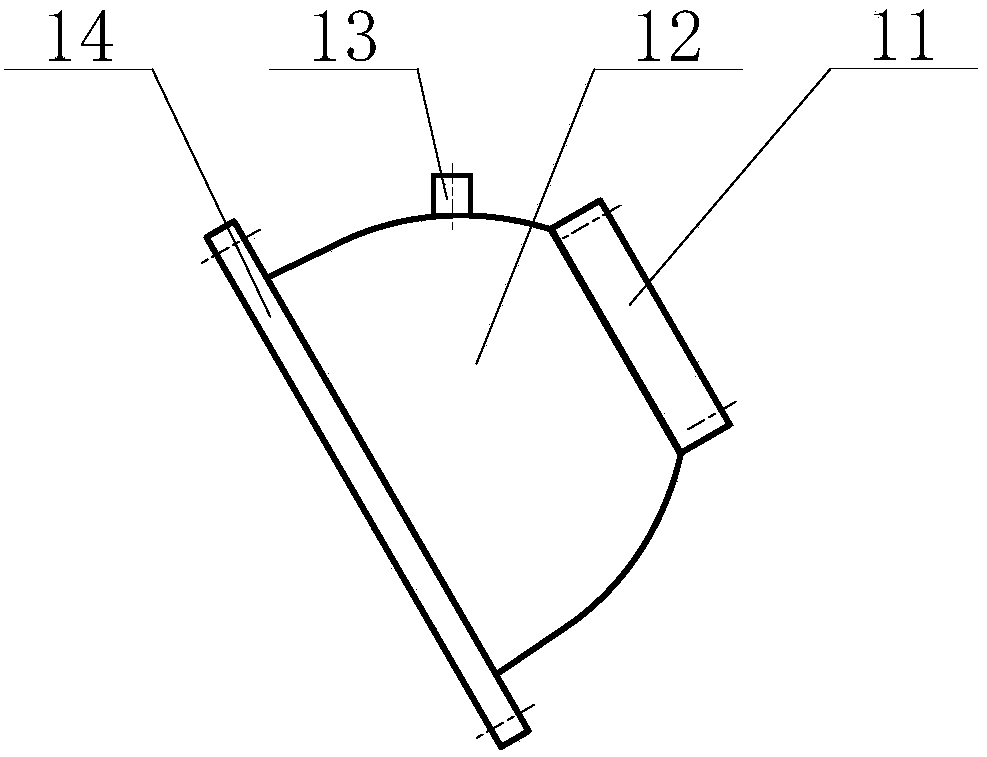

[0027] See attached figure 2 , the upper adapter bowl 1 includes: a small-diameter flange A11, a bowl body A12, and a large-diameter flange A14 connected in sequence; the exhaust valve port 13 is arranged on the bowl body A12, and the small-diameter flange A11 and the large-diameter flange A14 There is an end face seal structure on each.

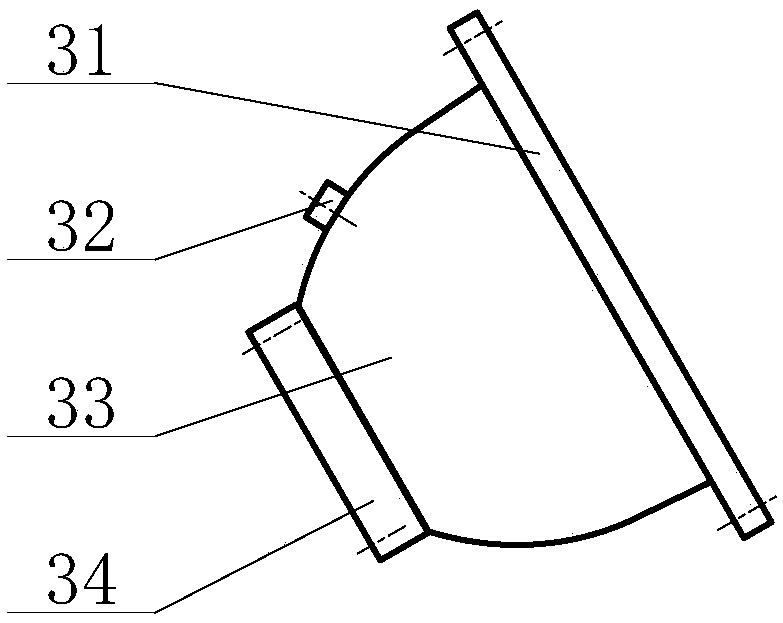

[0028] See attached image 3 , the lower adapter bowl 3 includes: the lower adapter bowl 3 includes: small-diameter flange B34, bowl body B33, and large-diameter flange B31 connected in sequence; the oil filling valve port 32 is arranged on the bowl body B33, and the small-diameter flange Both B34 and large-diameter flange B3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com