Non-equal support control method of advanced hydraulic support

A hydraulic support and control method technology, applied in the field of strong control, can solve problems such as roof damage and excessive disturbance, and achieve the effect of reducing damage and low initial support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

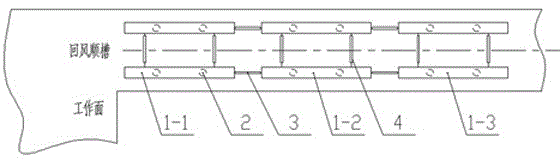

[0020] figure 1 Shown is the layout of the advance hydraulic support in the return air trough of a working face in a mine. It is a set of advance support supports composed of three sets of advance hydraulic supports. Overall, the advance support distance (distance to the working face) is 30m. In this embodiment, the leading hydraulic support group I1-1 is close to the working face, the leading hydraulic support group II1-2 is the middle frame, the leading hydraulic support group III1-3 is the leading frame, and push-pull jacks 3 are arranged between the adjacent two groups of leading hydraulic supports . The three groups of advanced hydraulic supports adopt the same type and number of columns 2 .

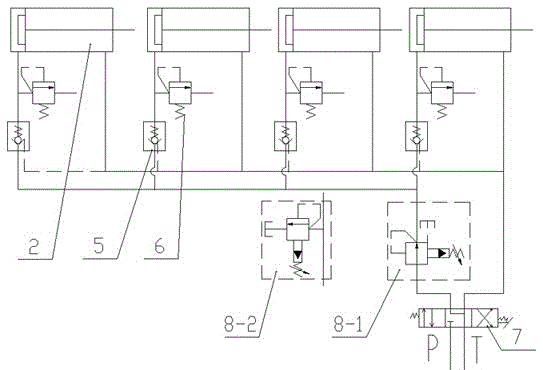

[0021] Such as figure 2 As shown, each group of advanced support columns adopts the same hydraulic control system, through a three-position four-way reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com