Supercharged internal combustion engine with exhaust-gas turbochargers arranged in series and method for operating an internal combustion engine of said type

An internal combustion engine, supercharged technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of high construction cost, inertial behavior, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

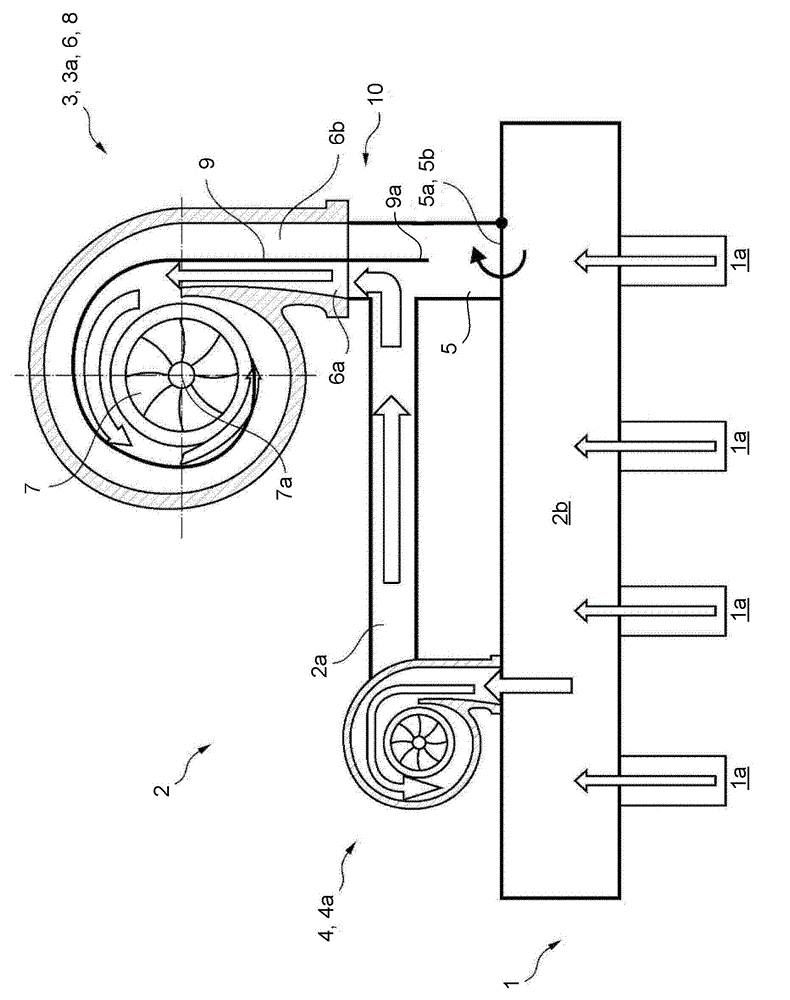

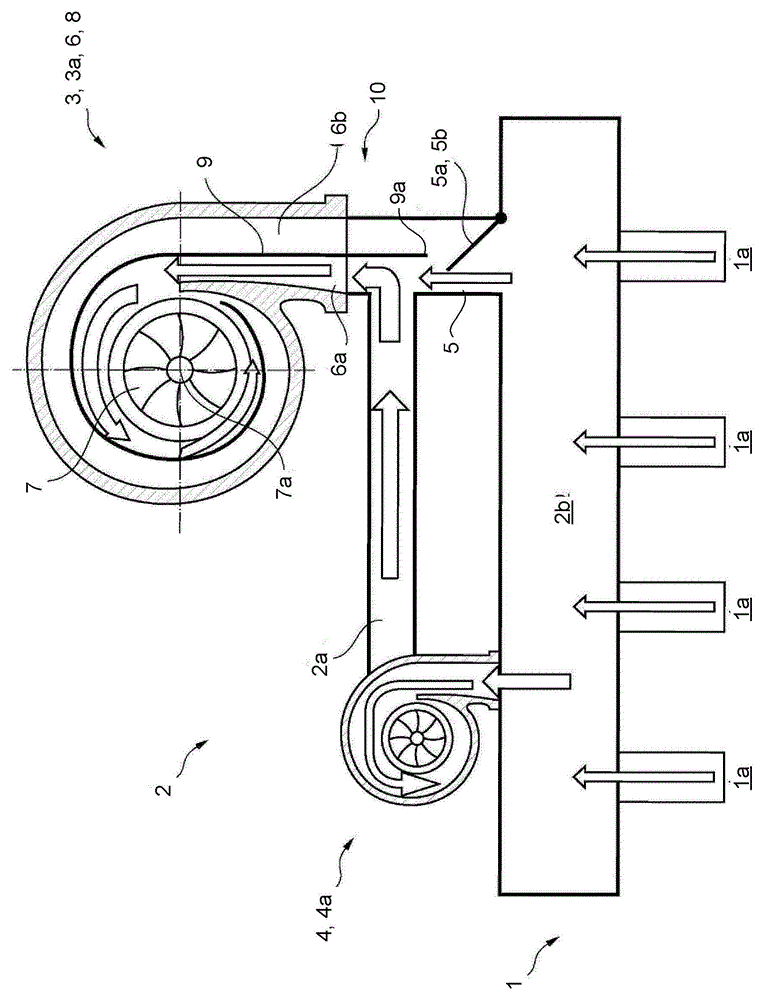

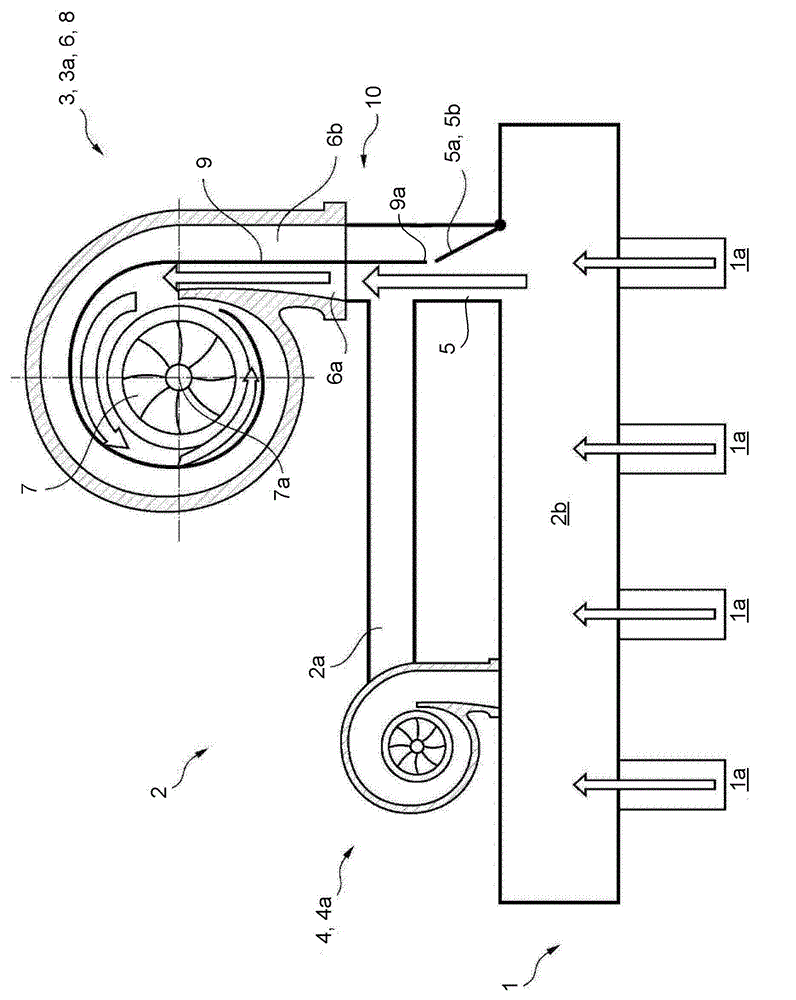

[0016] The present application relates to a supercharged / supercharged internal combustion engine. The supercharged internal combustion engine includes an intake system for supplying supercharged air and an exhaust emission system for discharging exhaust gas, and has at least two Two exhaust gas turbochargers in series, each of the exhaust gas turbochargers includes a turbine arranged in the exhaust gas discharge system and a compressor arranged in the intake system, and wherein the first exhaust gas turbocharger serves as The low-pressure stage and the second exhaust turbocharger serve as the high-pressure stage, the second turbine of the second exhaust turbocharger is arranged upstream of the first turbine of the first exhaust turbocharger, and the second exhaust turbine The second compressor of the supercharger is arranged downstream of the first compressor of the first exhaust turbocharger, and a first bypass line is provided, which branches from the exhaust discharge system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com