Hydraulic electromagnetic directional valve

An electromagnetic reversing valve and hydraulic technology, which is applied in the field of electromagnetic valves, can solve problems such as armature jamming, and achieve the effects of reducing back pressure, moving lightly and flexibly, and being easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

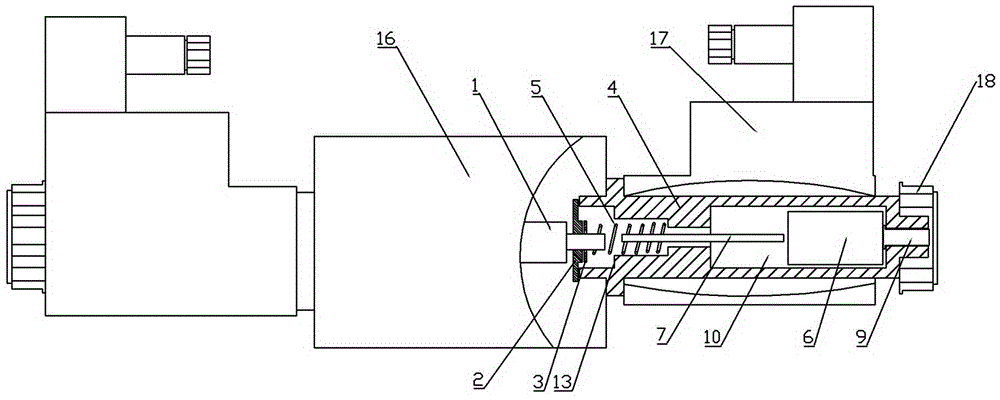

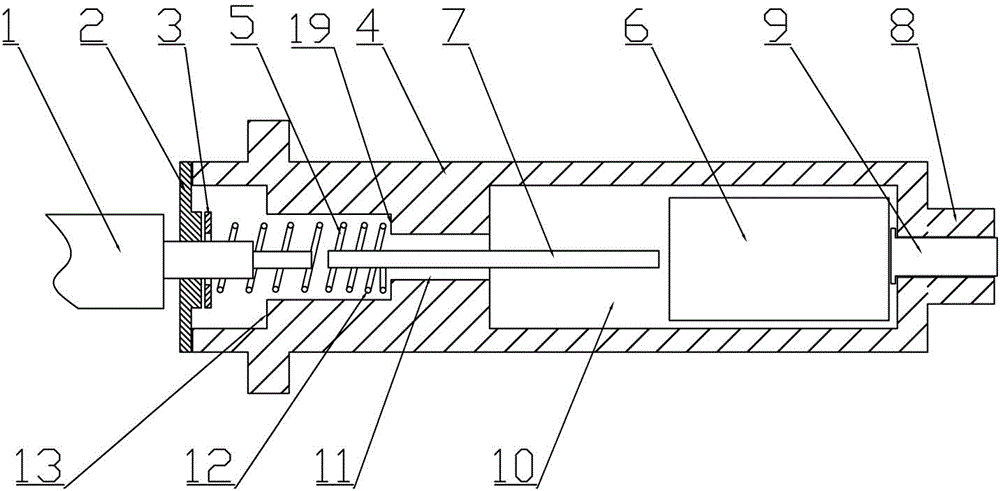

[0025] Embodiment 1: A hydraulic electromagnetic reversing valve, see figure 1 , figure 2 , image 3 It includes a valve body 16, a valve core 1 correspondingly arranged in the valve body, a magnetic sleeve 4 correspondingly connected with the valve body 16, and an armature 6 and a push rod correspondingly arranged in the inner cavity 10 of the magnetic sleeve 4 7. A reaction force spring 5 is also provided in the magnetic sleeve 4, and a limit step 19 is also correspondingly provided in the magnetic sleeve 4. One end of the reaction force spring 5 is in corresponding contact with the limit step 19, and the other One end is in corresponding contact with the magnetic core 1 via the magnetic core limiting piece 2 ; the diameter of the magnetic core limiting piece 2 is the same as the outer diameter of the end of the magnetic sleeve 4 . At the same time, a gasket 3 is also arranged between the magnetic core limiting piece 2 and the reaction force spring 5, and the magnetic cor...

Embodiment 2

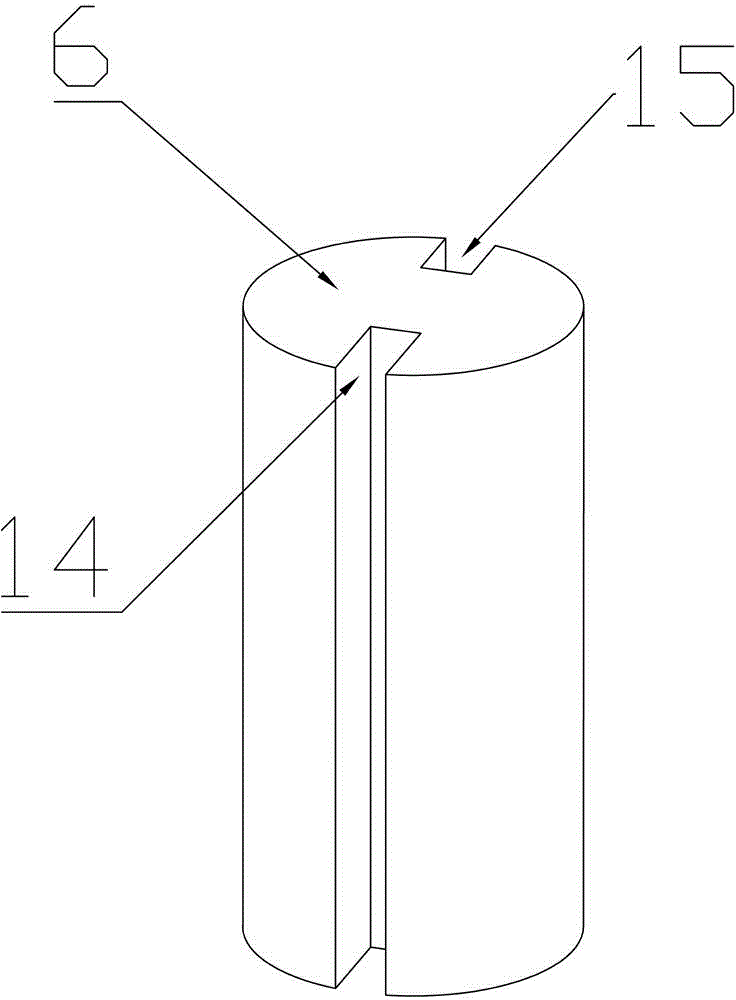

[0026] Example 2, such as Figure 1 to Figure 4 As shown, the similarities with Embodiment 1 will not be repeated, the difference is that the armature is also a cylindrical structure, and two through holes 20 connecting the two ends of the armature 6 are provided in the armature 6; The two through holes are symmetrical about the axis of the armature 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com