Bolted pair with throttling element

A technology of throttling element and connecting pair, which is applied in the direction of threaded connection, pipe element, passing element, etc., can solve the problems of cavitation, flashing and noise of oil-filled bolts, and achieve the effect of avoiding cavitation and realizing throttling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

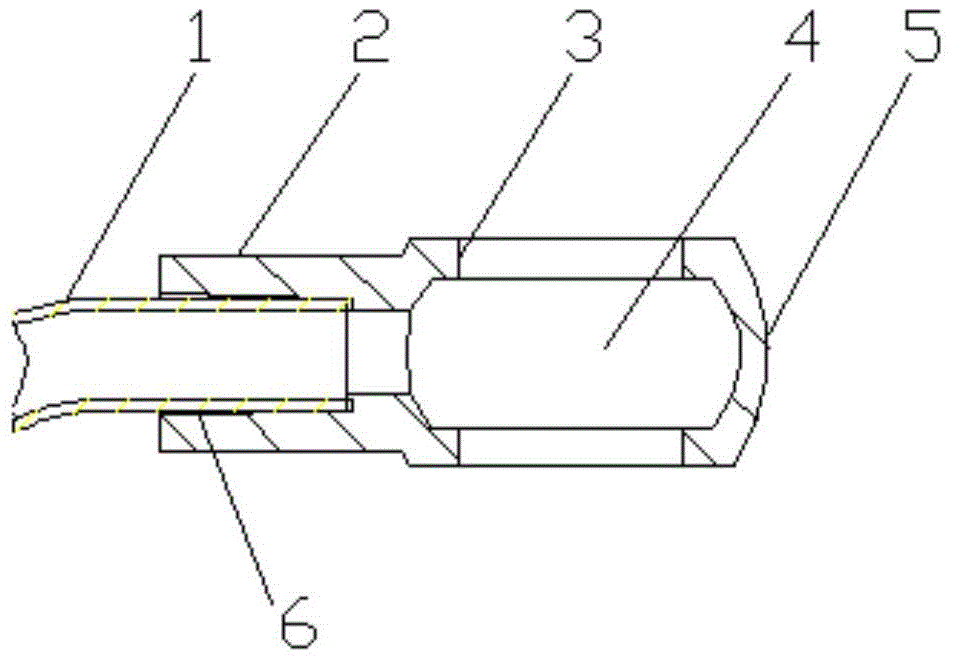

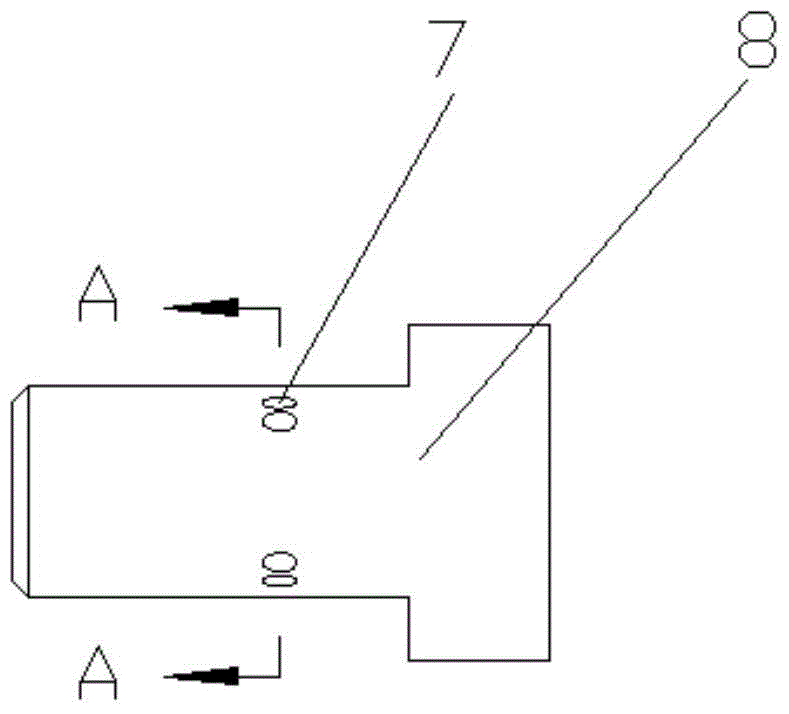

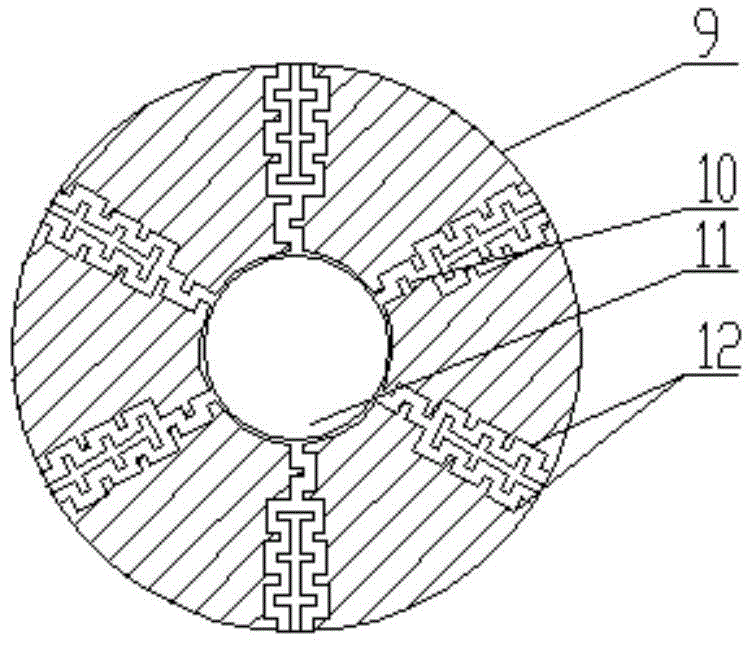

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of the driven wheel of the present invention; image 3 It is a cross-sectional view of the drive shaft of the present invention. The throttling oil-passing bolt 8 connection pair in this embodiment includes the oil-passing bolt 8 and the oil-passing joint connected with the oil-passing bolt 8 through thread fit. The screw rod 9 of the bolt 8 is provided with an oil passage 11 along the axial direction and the side wall of the screw rod 9 is provided with a labyrinth-shaped orifice communicating with the oil passage 11. The flow path of the labyrinth orifice is a labyrinth, that is, its flow The path has one or more bends, the oil from outside the oil bolt 8 enters the oil passage 11 through the labyrinth orifice, and when passing through these bends, the flow direction of the oil will change, and then The throttling effect is realized, so that the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com