LED tubing lamp structure

A technology of LED tube lights and LED lamp beads, which is applied to the components of lighting devices, lighting and heating equipment, point light sources, etc., can solve the problems of time-consuming threading process, lead wire dislocation, and affecting work efficiency, etc., to achieve connection and assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

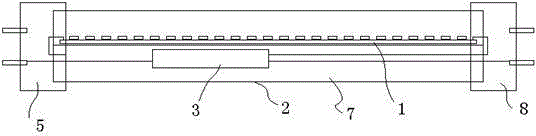

[0022] Such as figure 2 As shown, the structure of an LED tube lamp includes a lamp board 1, a lamp board frame 2 and a power supply 3, wherein the rectifier IC 10 in the power supply 3 is at one end of the lamp board 1, and the constant current circuit 4 in the power supply is at the end of the lamp board 1 At the other end, the lamp bead 12 is between the rectifier IC10 and the constant current circuit 4; The non-welding surface 13 is thermally connected to the plane surface 11 of the lamp panel frame 2; an AC input terminal of the rectifier IC and the adjacent first lamp holder 5 (the left end in the figure) have an AC first welding wire plate 6 and an AC first welding wire The disc 6 is electrically connected to the terminal of the first lamp holder 5; the other AC input terminal of the rectifier IC is routed through the lamp board to the second AC welding wire disc 9 at the other end of the lamp board near the second lamp holder 8 (the right end in the figure). Above, t...

Embodiment 2

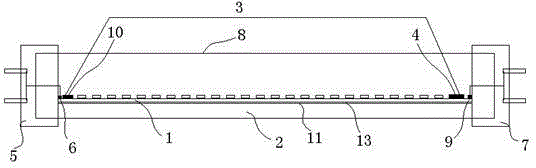

[0024] Such as image 3 As shown, the structure of an LED tube lamp includes a lamp board 1, a lamp board frame 2 and a power supply 3, wherein the rectifier IC 10 in the power supply 3 is at one end of the lamp board 1, and the constant current circuit 4 in the power supply is at the end of the lamp board 1 At the other end, the lamp bead 12 is between the rectifier IC10 and the constant current circuit 4; The non-welding surface 13 is thermally connected to the plane surface 11 of the lamp panel frame 2; an AC input terminal of the rectifier IC and the adjacent first lamp holder 5 (the left end in the figure) have an AC first welding wire plate 6 and an AC first welding wire The disc 6 is electrically connected to the terminal of the first lamp holder 5; the other AC input terminal of the rectifier IC is routed through the lamp board to the second AC welding wire disc 9 at the other end of the lamp board near the second lamp holder 8 (the right end in the figure). Above, th...

Embodiment 3

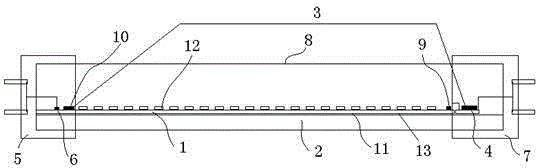

[0026] Such as Figure 4 As shown, the structure of an LED tube lamp includes a lamp board 1, a lamp board frame 2 and a power supply 3, wherein the rectifier IC 10 in the power supply 3 is at one end of the lamp board 1, and the constant current circuit 4 in the power supply is at the end of the lamp board 1 At the other end, the lamp bead 12 is between the rectifier IC10 and the constant current circuit 4; The non-welding surface 13 is thermally connected to the plane surface 11 of the lamp panel frame 2; an AC input terminal of the rectifier IC and the adjacent first lamp holder 5 (the left end in the figure) have an AC first welding wire plate 6 and an AC first welding wire The disc 6 is electrically connected to the terminal of the first lamp holder 5; the other AC input terminal of the rectifier IC is routed through the lamp board to the second AC welding wire disc 9 at the other end of the lamp board near the second lamp holder 8 (the right end in the figure). Above, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com