Patents

Literature

32results about How to "No dislocation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

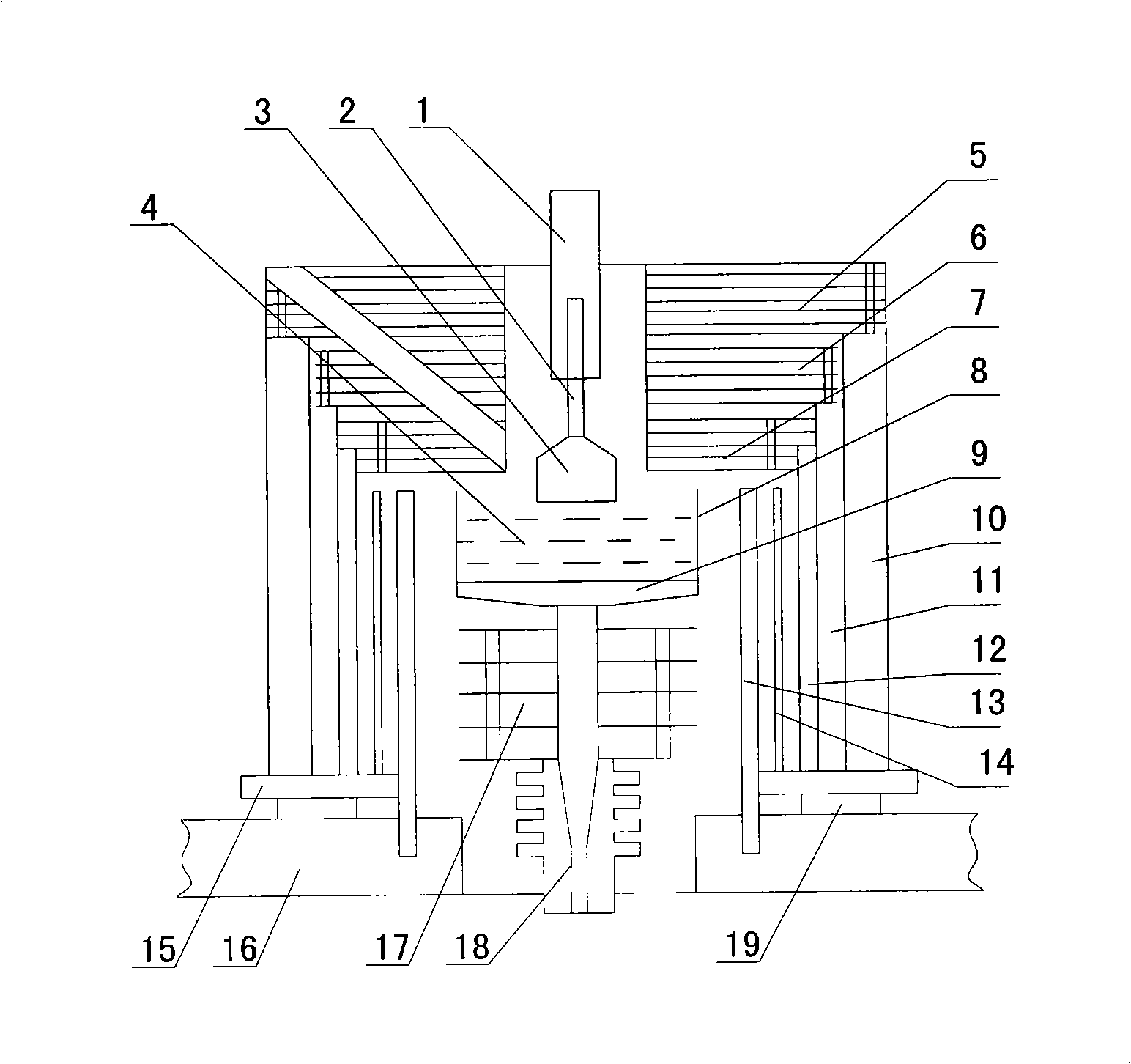

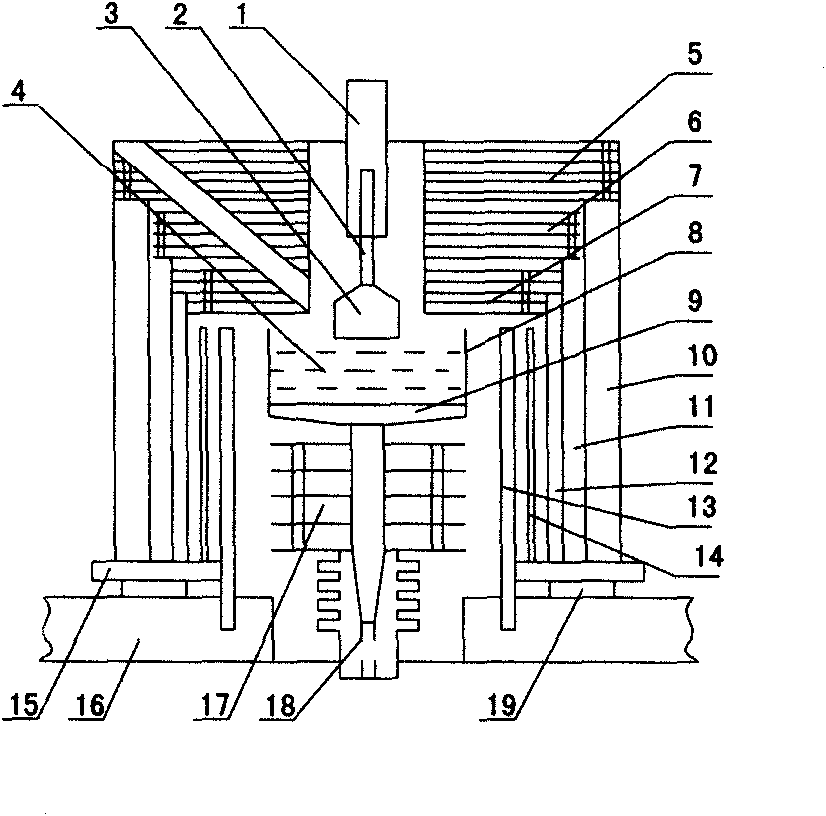

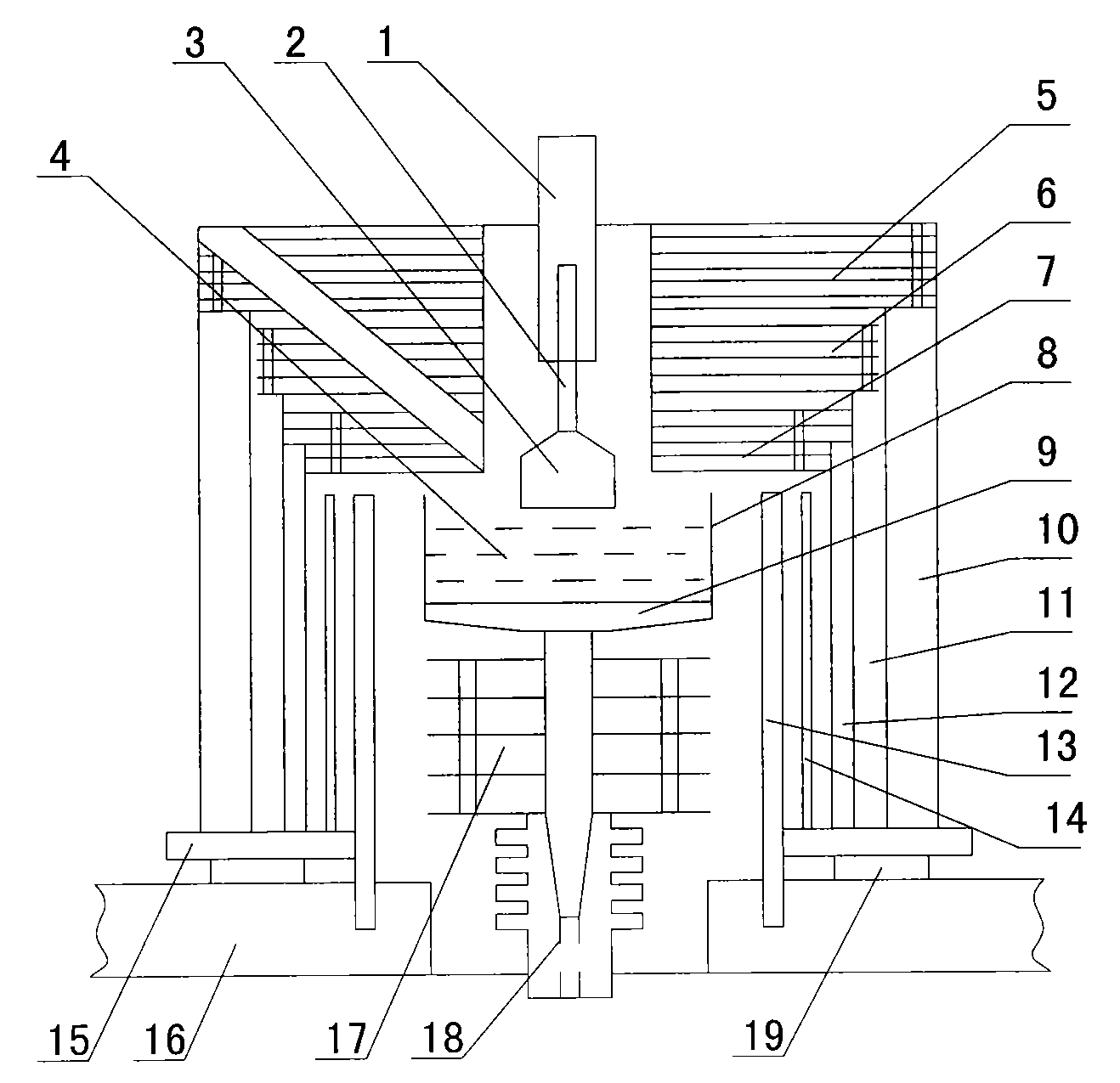

Growth device of large size non-core YAG series laser crystal and growth process thereof

ActiveCN101338453AIncrease concentrationNo corePolycrystalline material growthBy pulling from meltHigh concentrationCrystal growth

The invention discloses a grower and a growing method of a laser crystal that belongs to YAS series with large size and no core, which belongs to the crystallization technology of the laser crystal. The invention comprises the grower adopting a Mo crucible pulling method heated by resistance and the crystal growing method comprising two procedures and four phases. The laser crystal of YAS series provided by the invention has large size of 35 to 50mm, high concentration (reaching 2.0at percent), no core, no dislocation and no scattering. In addition, the growing technology is stable; growing cycle is short; cost is low; and the yield of the crystal is high with above 85 percent.

Owner:成都东骏激光股份有限公司

Electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe

ActiveCN103982142AExtended service lifeIncreased microhardnessDrilling rodsCorrosion preventionWear resistantAcid washing

The invention relates to an electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe, and belongs to the field of oil field oil pipes. The inner surface of the oil pipe is electroplated with an amorphous state nickel-based alloy corrosion-resistant wear-resistant protection layer. The thickness of the protection layer is 20-50 microns. The protection layer is electroplated by the steps of oil removing, water washing, acid washing, water washing, activating, deionized water cleaning, electroplating, water washing and thermal treatment. Treatment is performed in oil removing liquid for 5-10 minutes; in acid washing, an oxide film is removed from a sulfur solution till the natural color of metal is exposed; in electroplating, nickel alloy electroplating liquid is adopted, the PH value is adjusted to 2-6 by using nickel carbonate, the temperature is more than or equal to 60 DEG C, the current density is 2-8 A / dm<2>, and the electroplating time is 2 hours; in thermal treatment, the temperature is kept at 200-300 DEG C for 1.5 hours. The oil pipe has the advantages of high microhardness, resistance to acid and alkali corrosion, high wear resistance and long service life.

Owner:胜利油田金岛实业有限责任公司

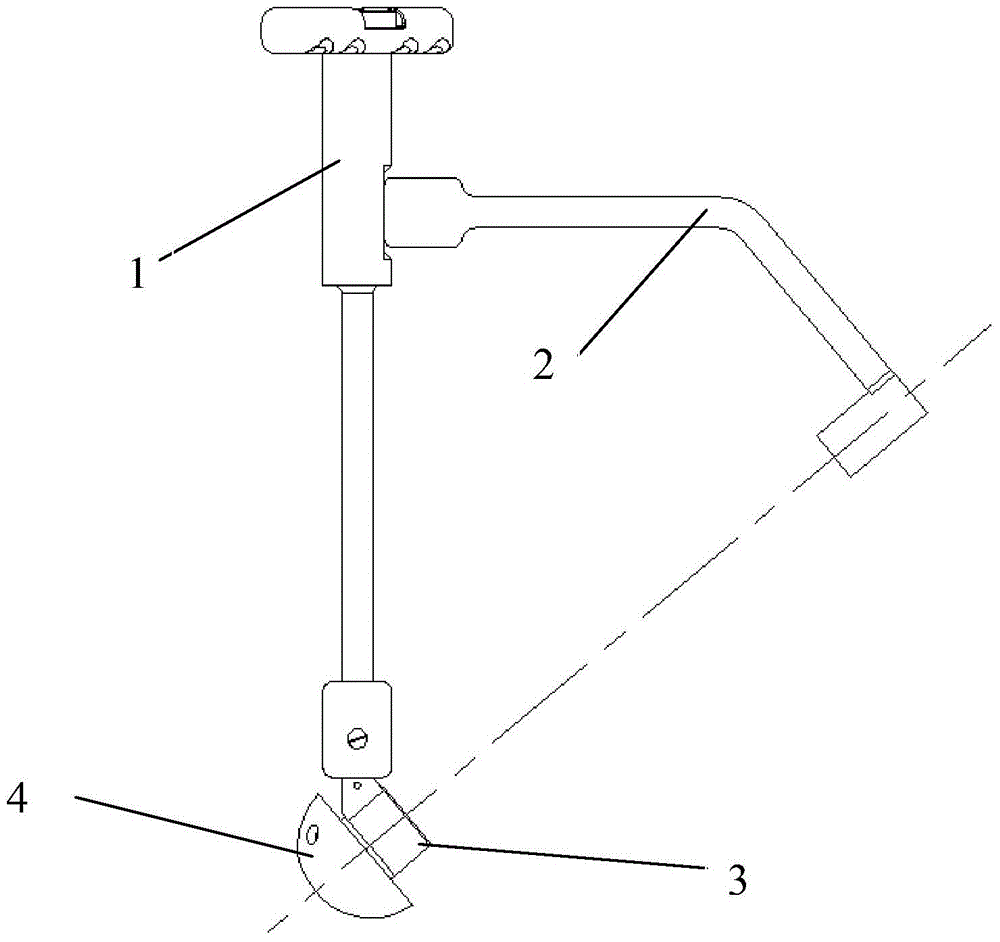

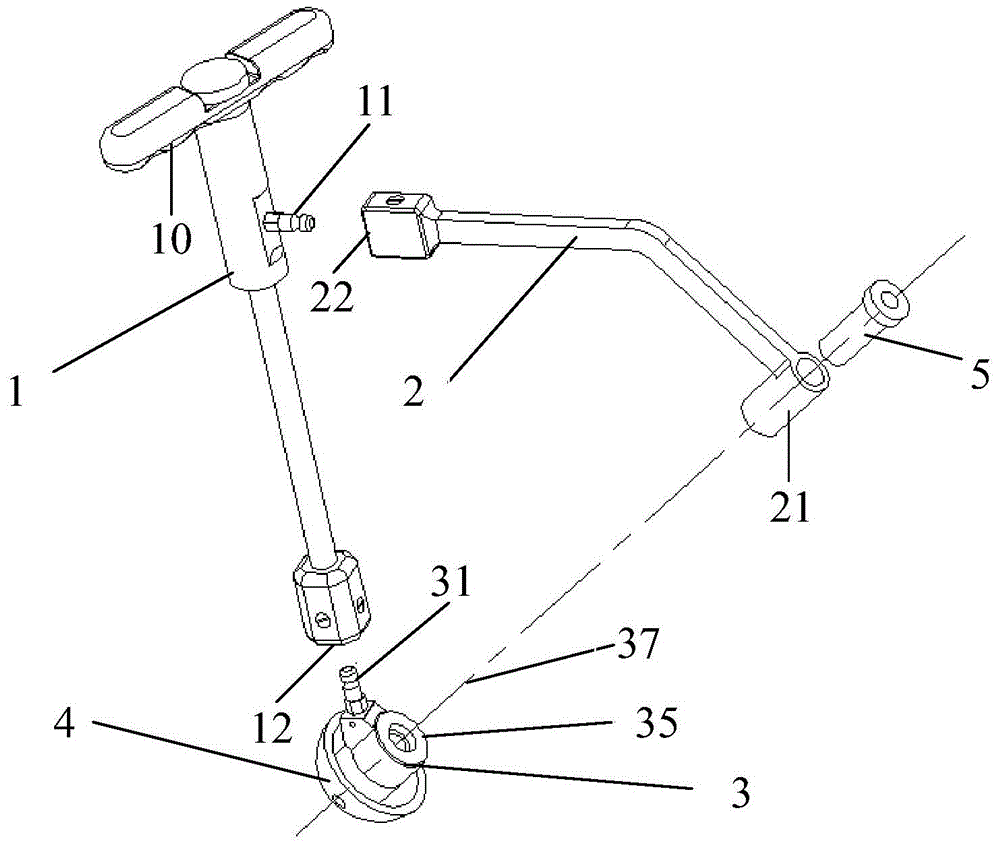

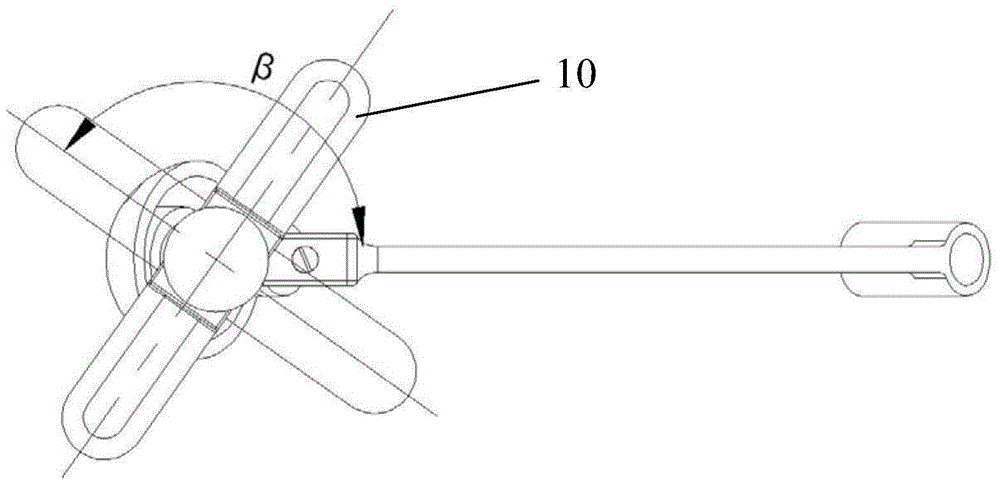

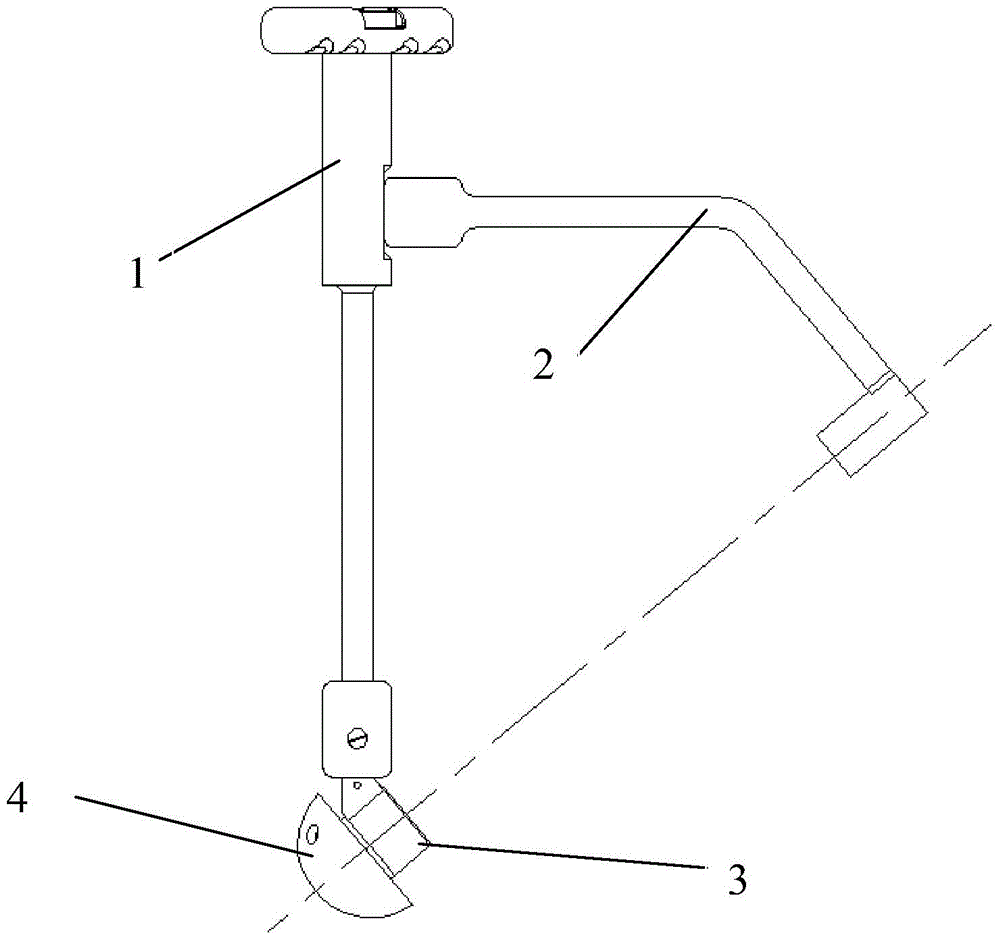

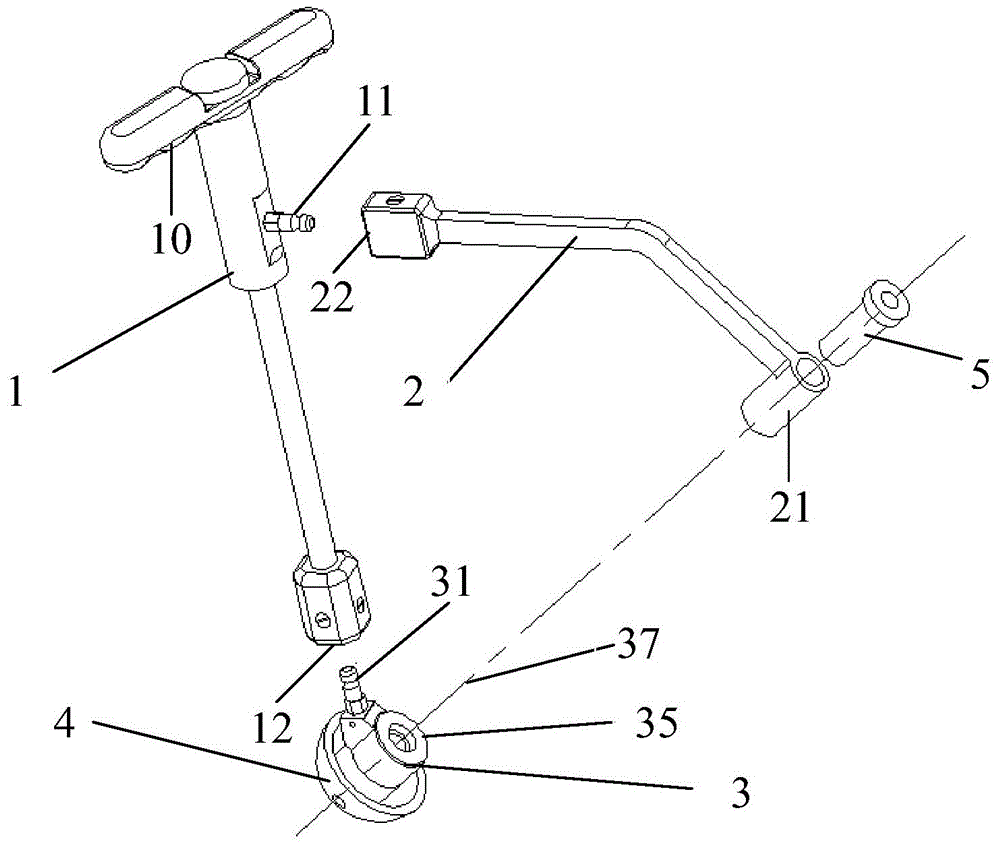

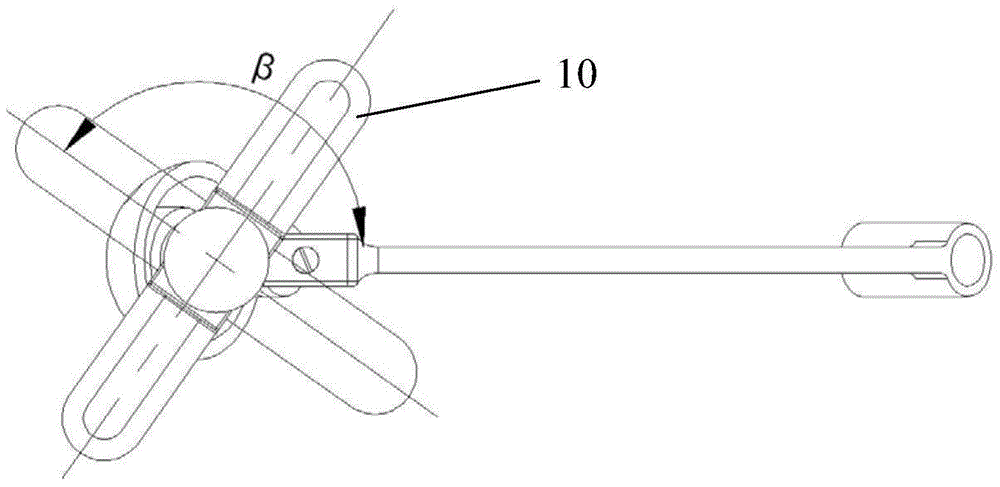

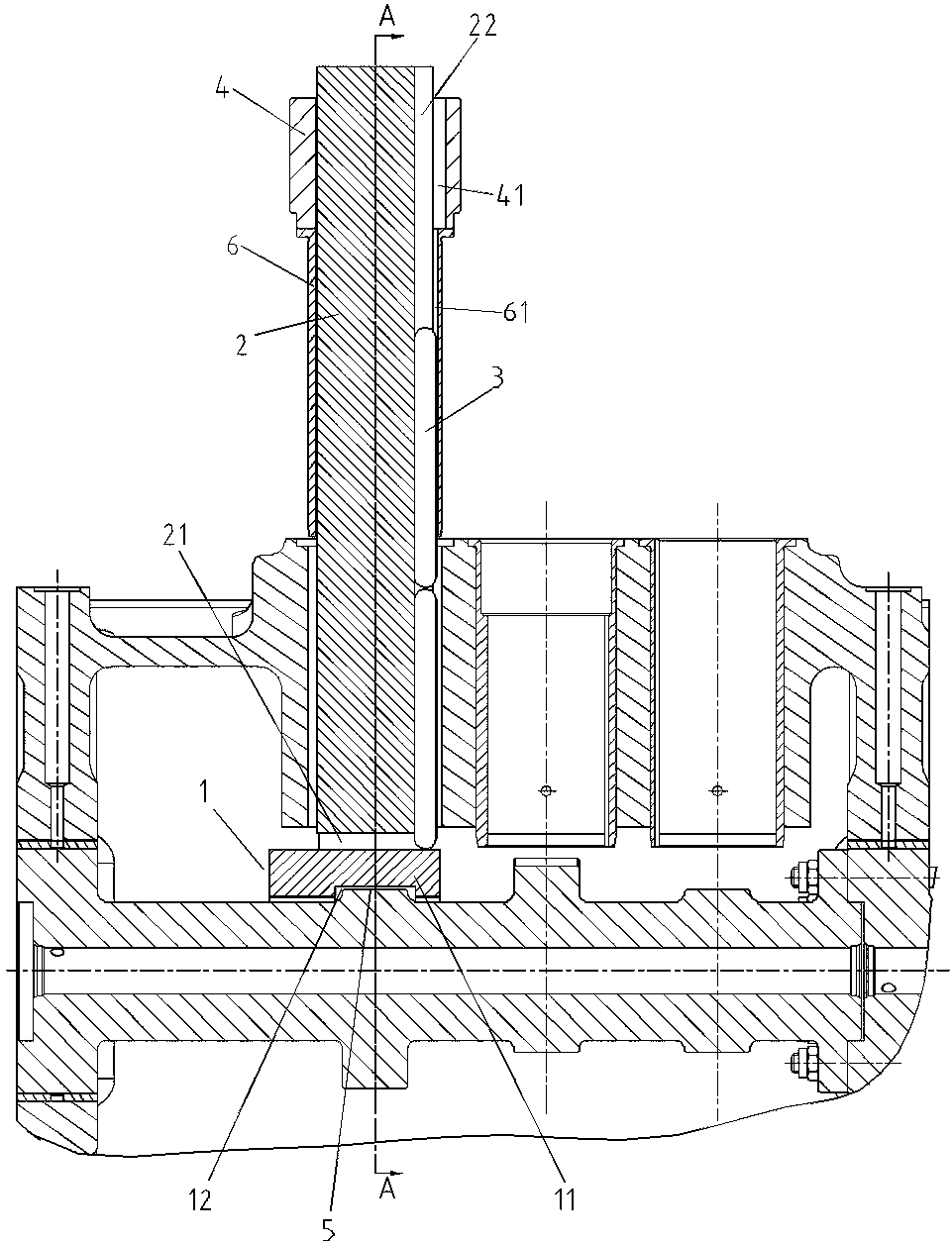

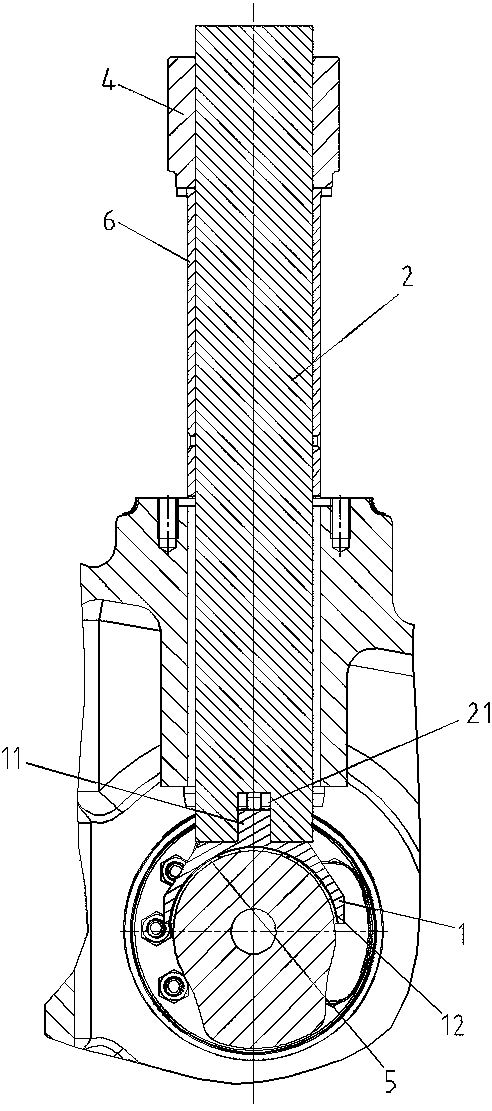

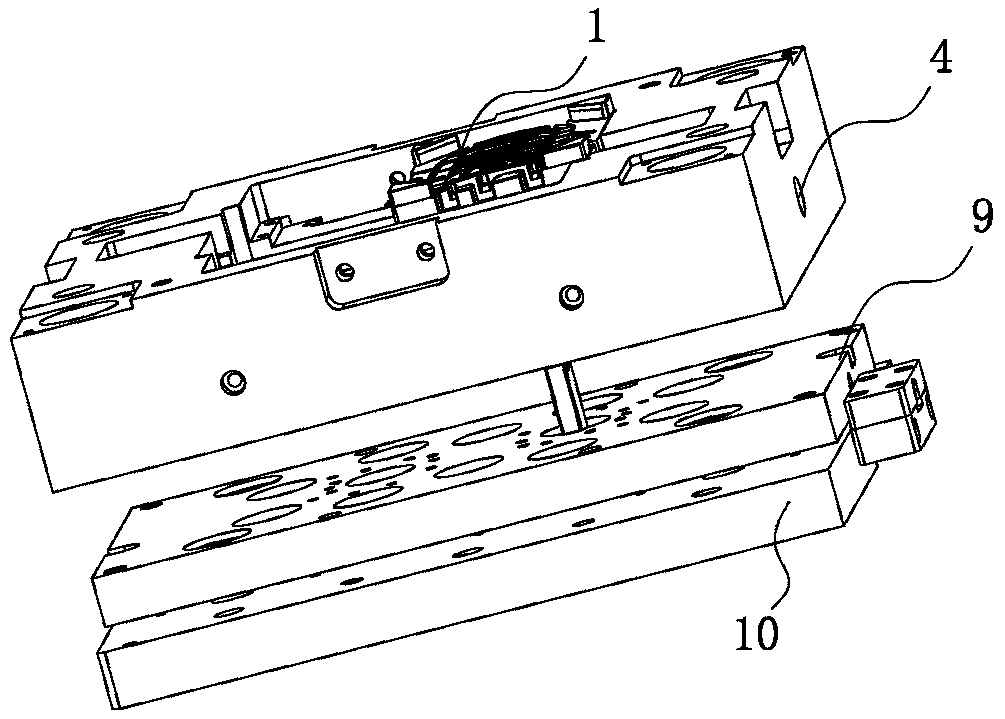

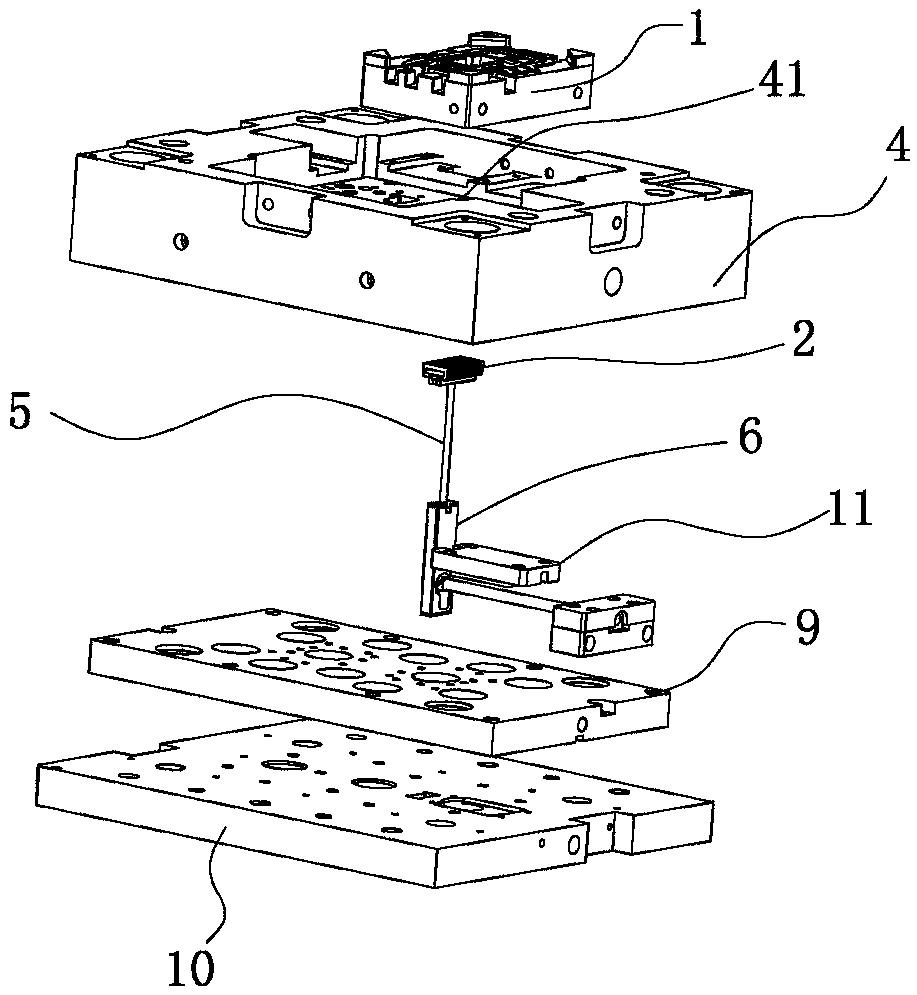

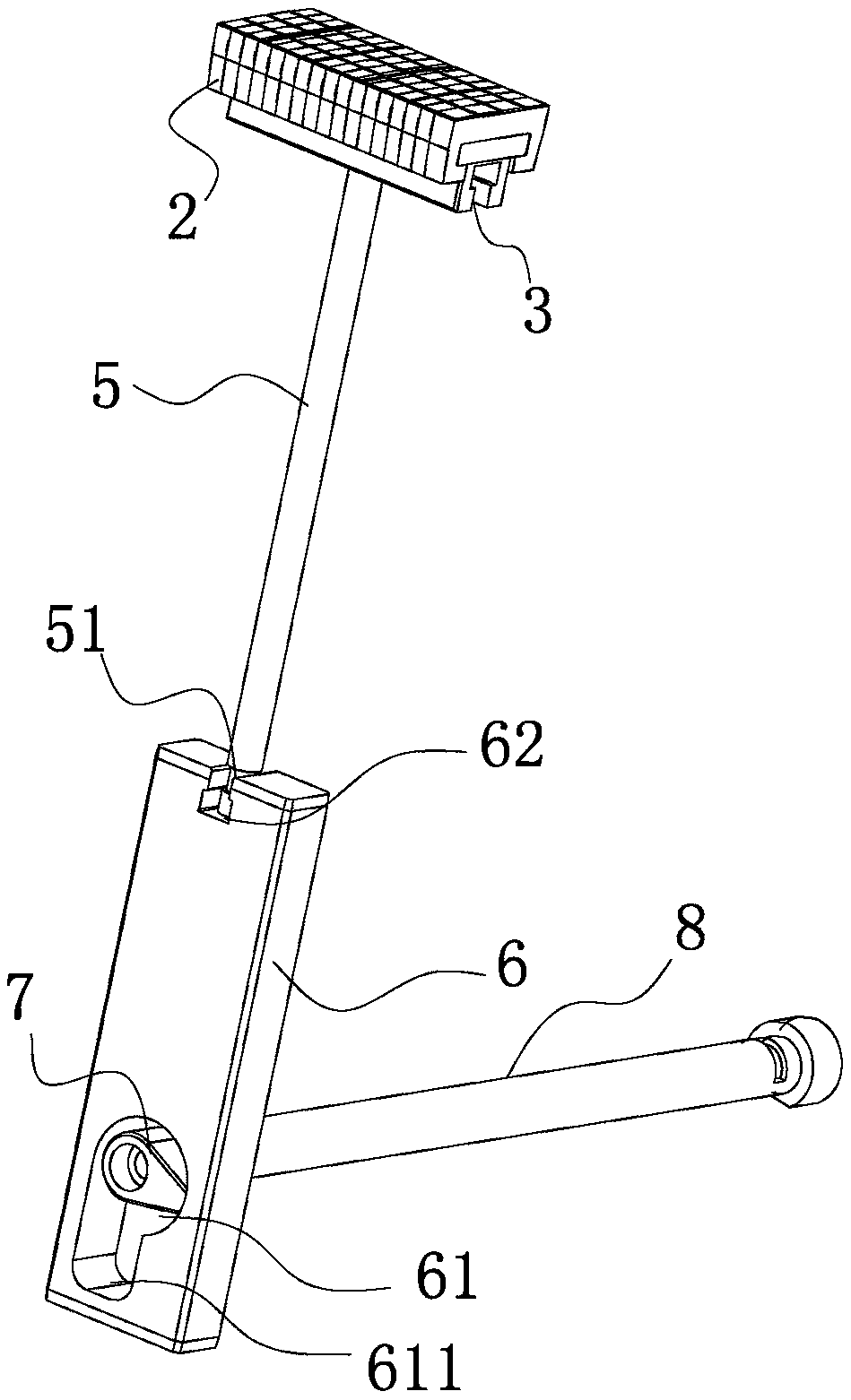

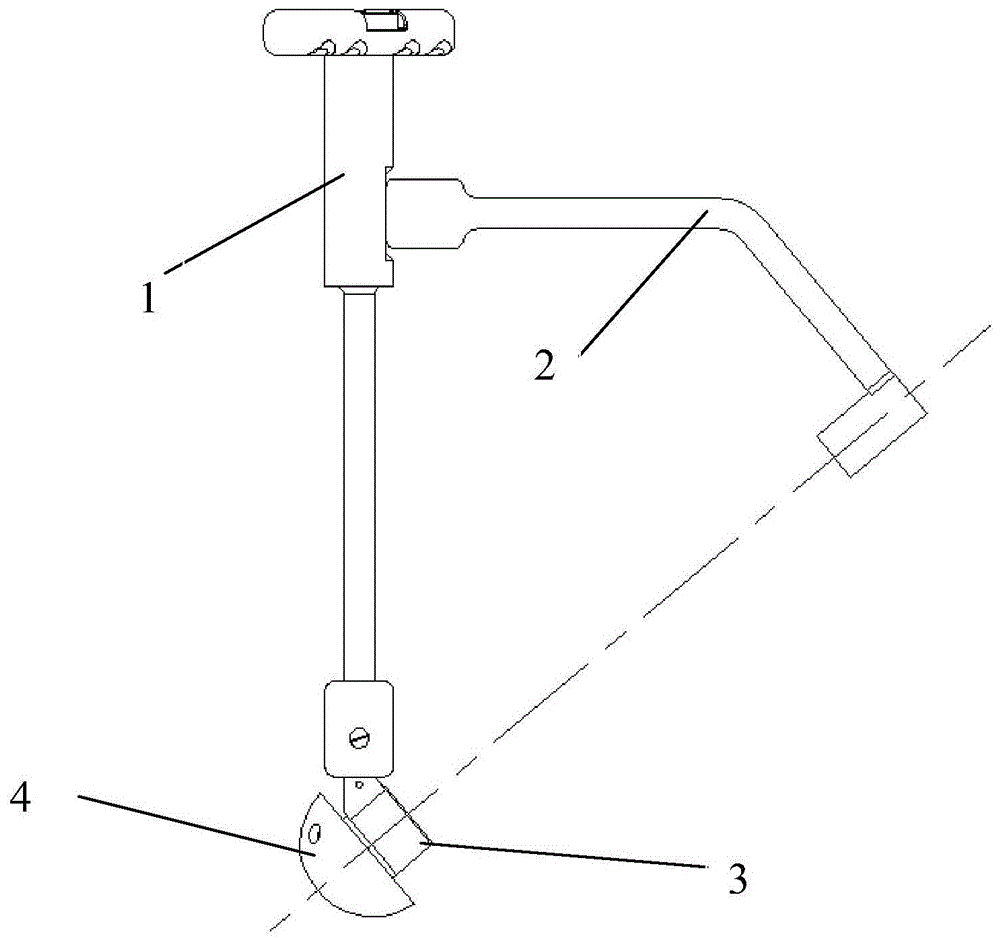

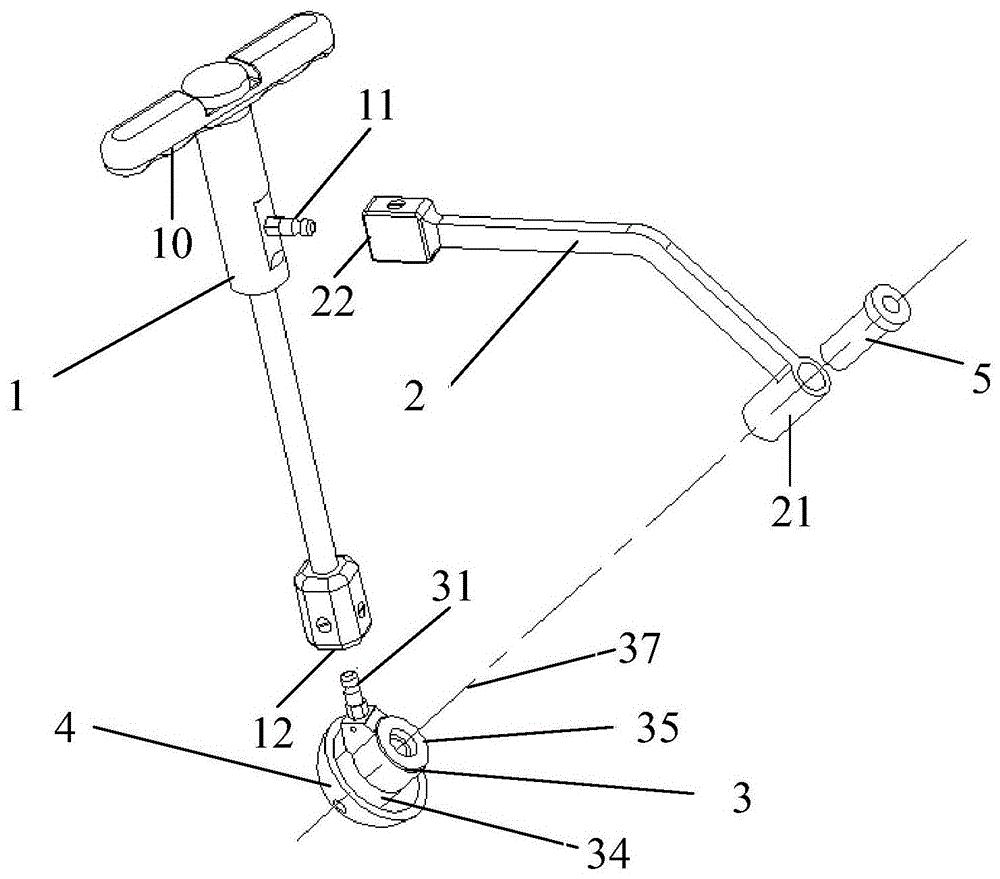

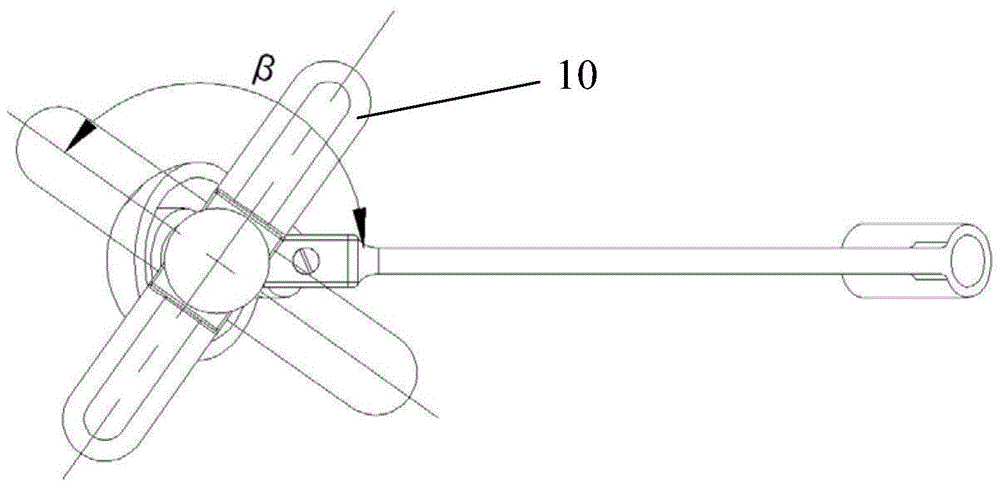

Guide system for hip replacement and using method thereof

ActiveCN105012054AShorten completion timeShorten operation timeJoint implantsAcetabular componentCompletion time

The invention discloses a guide system for hip replacement and a using method thereof. The guide system comprises a handle, a guide connecting rod, an acetabular cup connector and a sleeve. The lower end of the handle is connected with the acetabular cup connector. One end of the guide connecting rod is connected with the side close to the upper end of the handle, a sleeve hole is formed in the other end of the guide connecting rod, and the sleeve is nested into the sleeve hole. The acetabular cup connector comprises a mounting shaft which can be connected with an acetabular cup in a rotating mode, and the center axis of the sleeve is roughly overlapped with the axis of the mounting shaft. According to the guide system for hip replacement and the using method thereof, the guide system is easy to assemble and disassemble and convenient, quick and accurate to use, the completion time of minimally invasive surgery is greatly shortened, any muscle and any joint capsule do not need to be cut off in the operation process, an acetabular component can be accurately positioned, inserted and pressed in a matched mode, and dislocation can be avoided.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

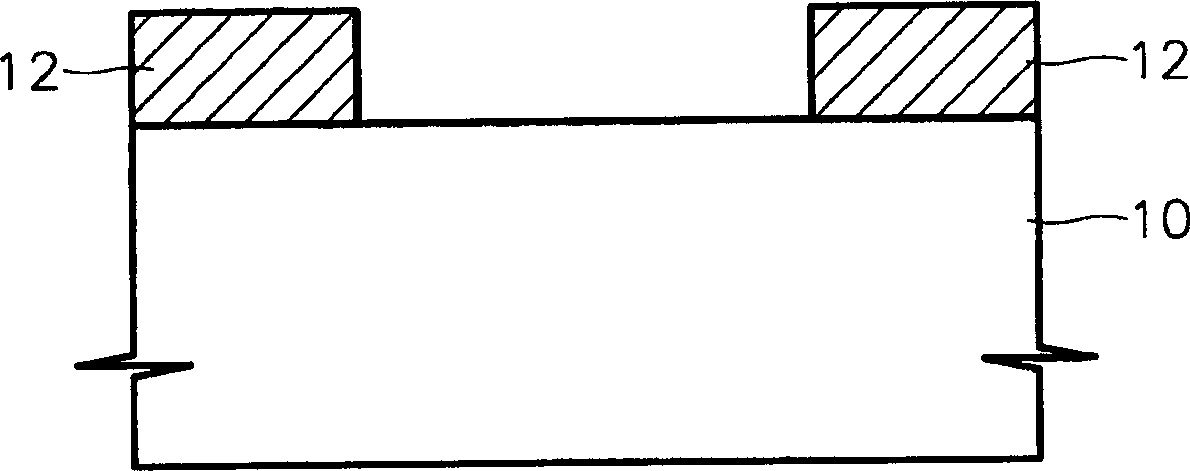

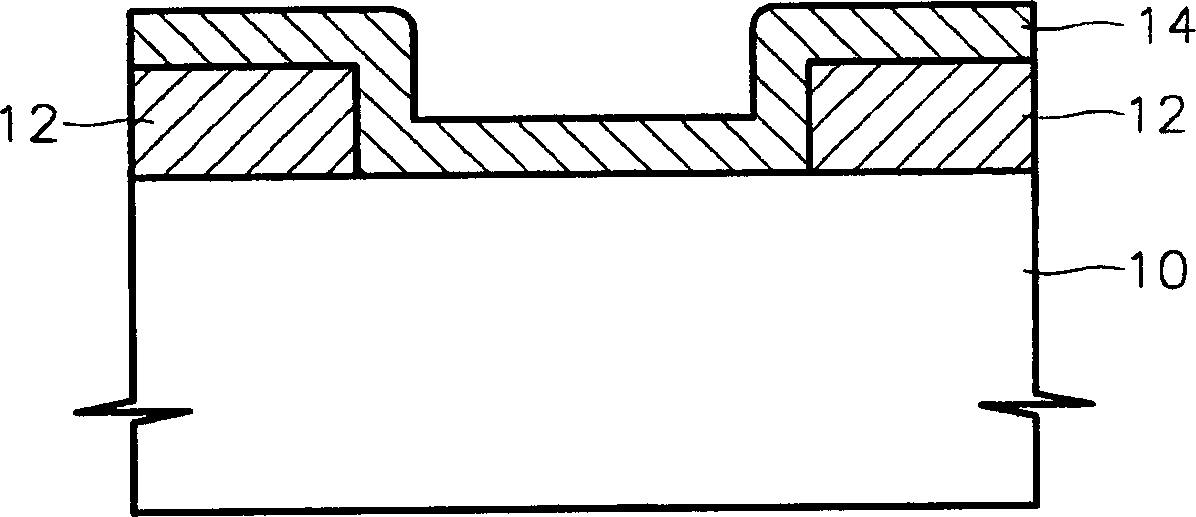

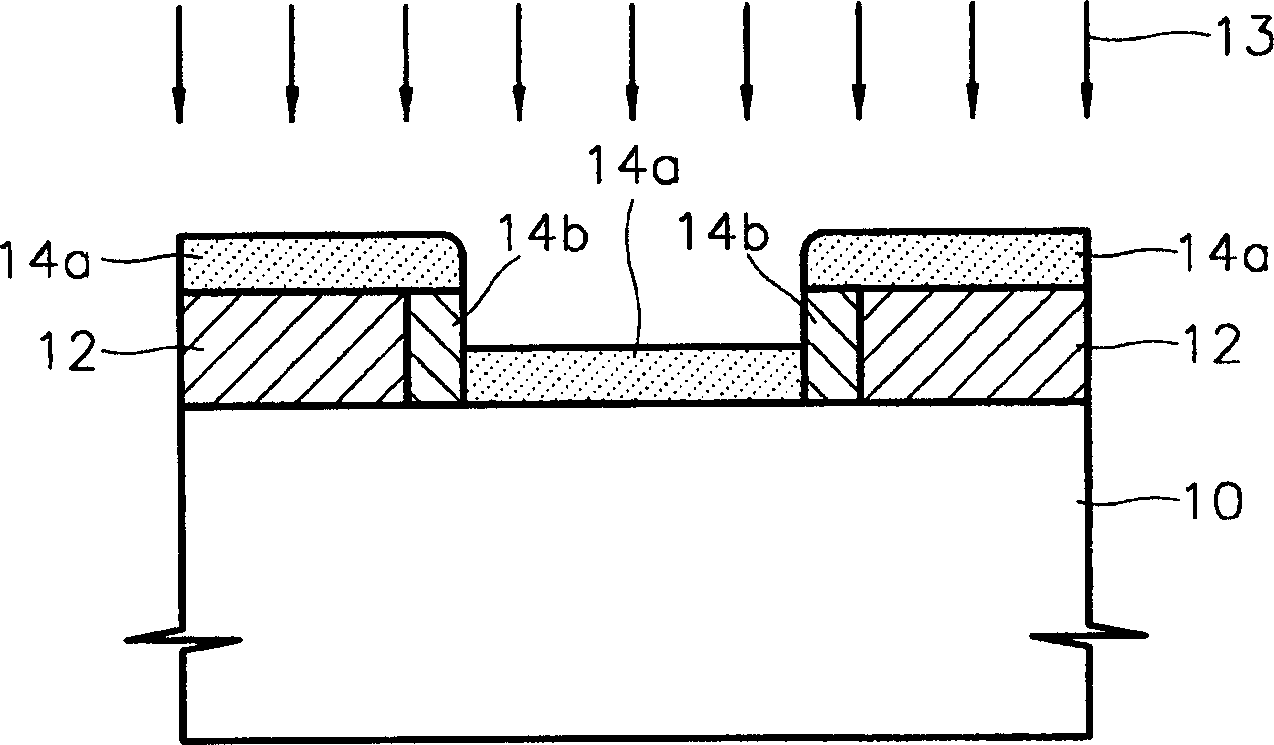

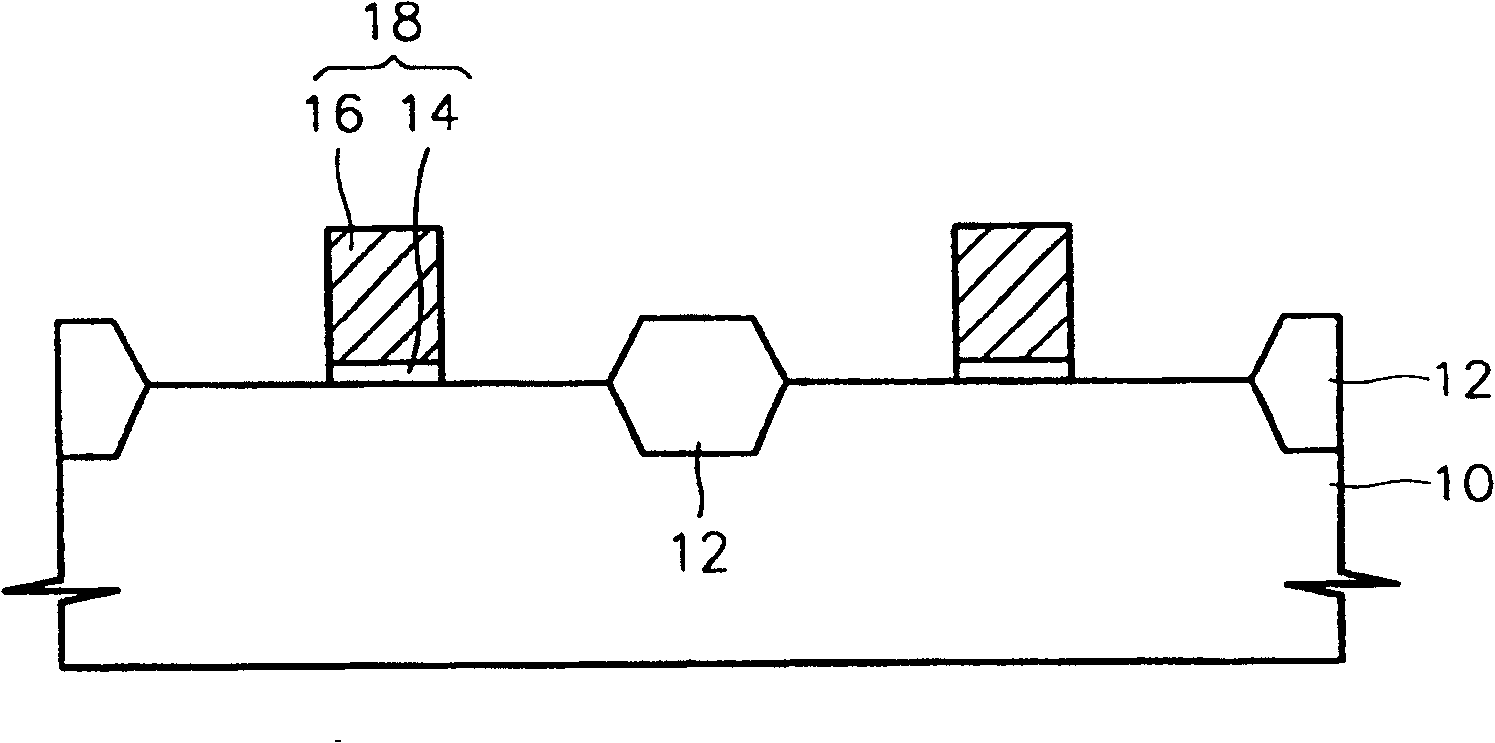

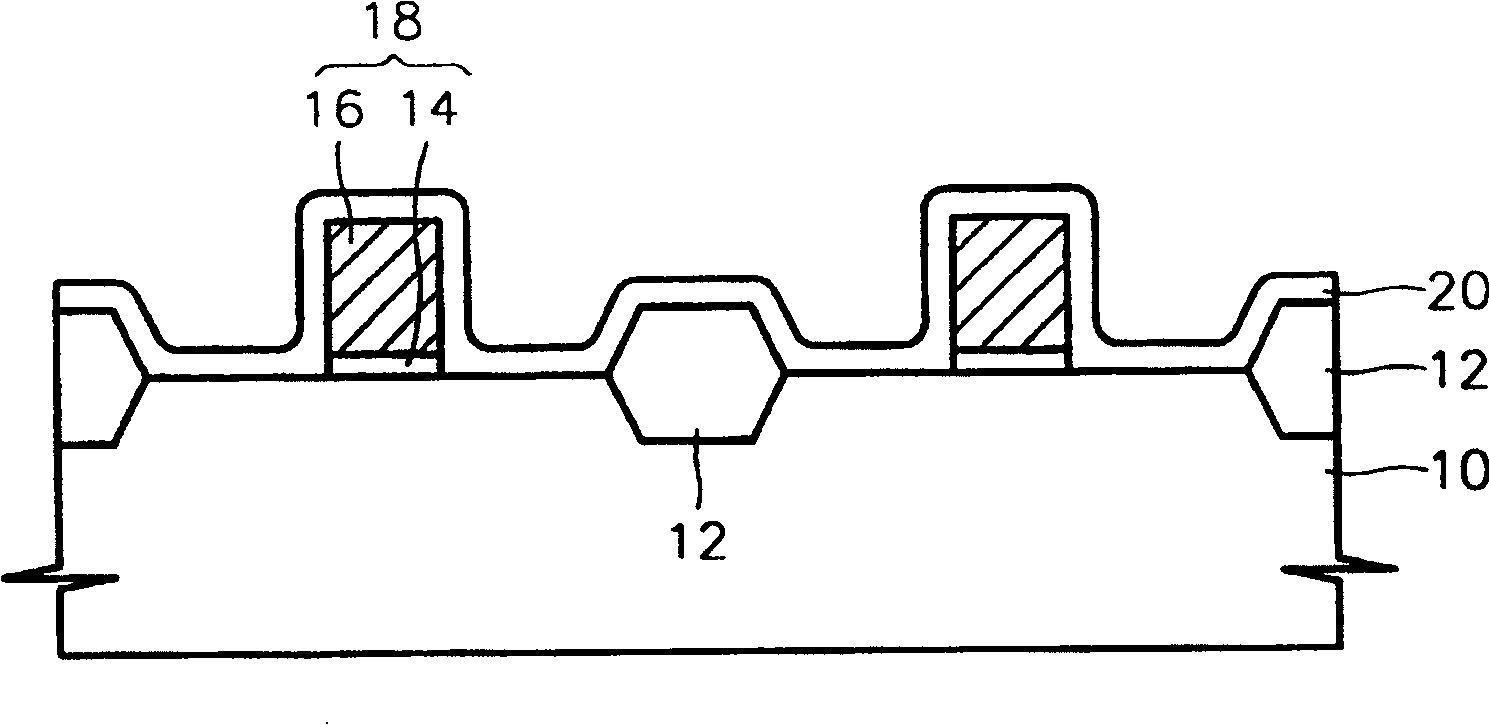

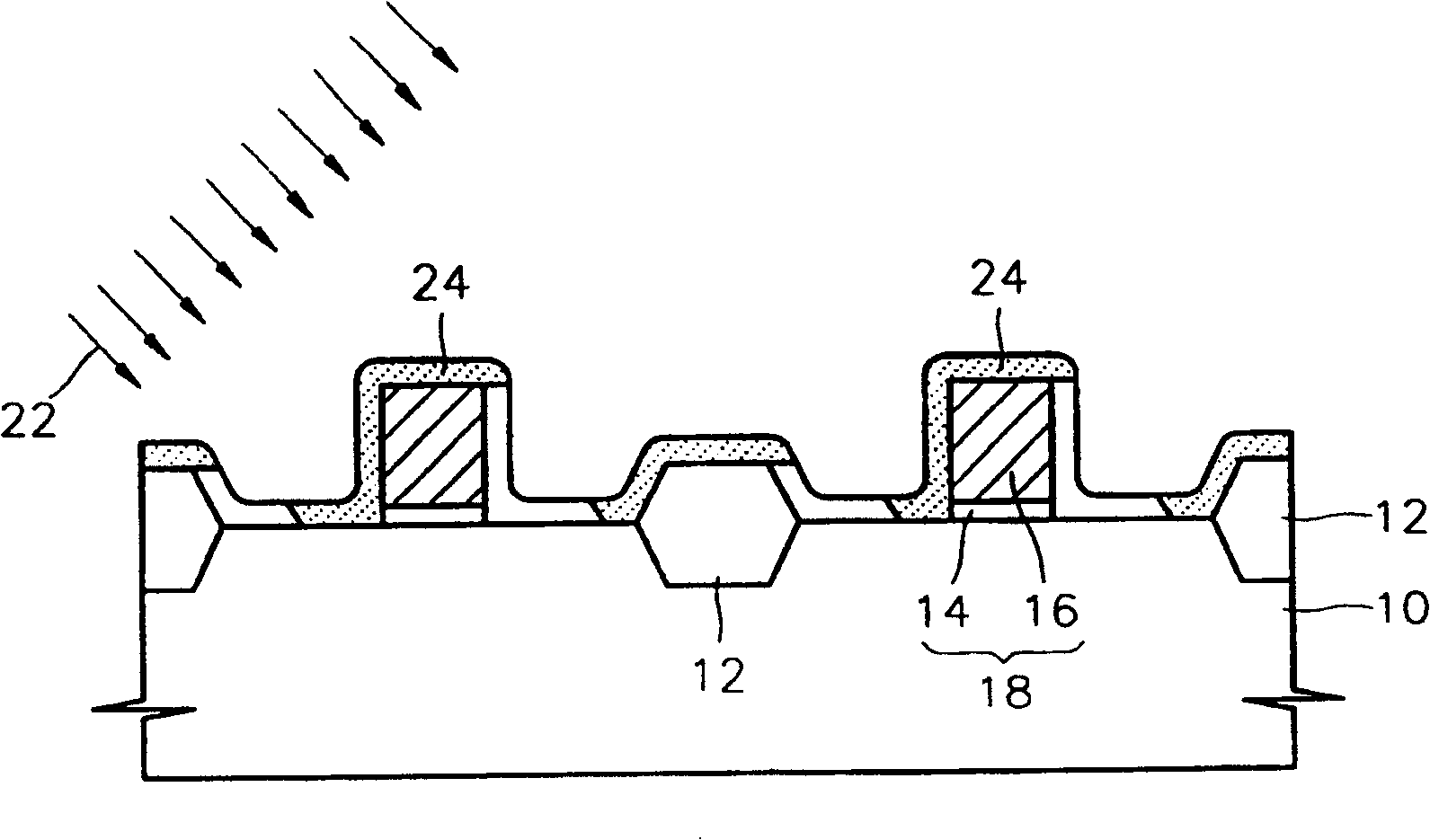

Method of mfg. integrated circuit with shallow junction

InactiveCN1416166APrecise control of doping concentrationNo dislocationTransistorSemiconductor/solid-state device manufacturingSolid phasesIntegrated circuit

A method of fabricating an integrated circuit having shallow junctions is provided. A SOG layer containing impurities is formed on a semiconductor substrate. Impurity ions are additionally implanted into the SOG layer by a plasma ion implantation method to increase the concentration of impurities in the SOG layer. The impurity ions contained in the SOG layer having the increased concentration of impurities are rapidly heat-treated and diffused into the semiconductor substrate by a solid phase diffusion method to form shallow junctions. As a result, the concentration of impurities is precisely controlled by the plasma ion implantation method, and impurity ions are not directly implanted into the semiconductor substrate. Thus, the crystal structure of the semiconductor substrate is not damaged. Moreover, if the method of fabricating the integration circuit having the shallow junctions is applied after a gate electrode is formed, a LDD region and a highly doped source / drain region can be formed by a self-aligned method.

Owner:ELECTRONICS & TELECOMM RES INST

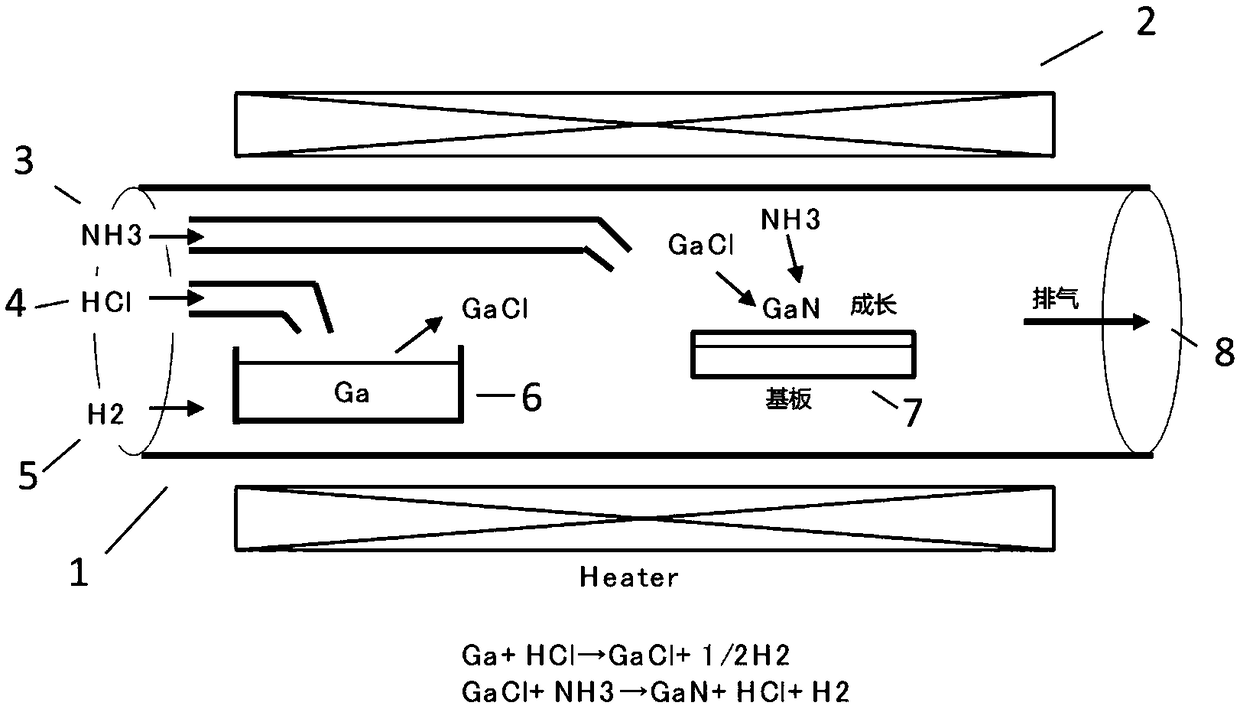

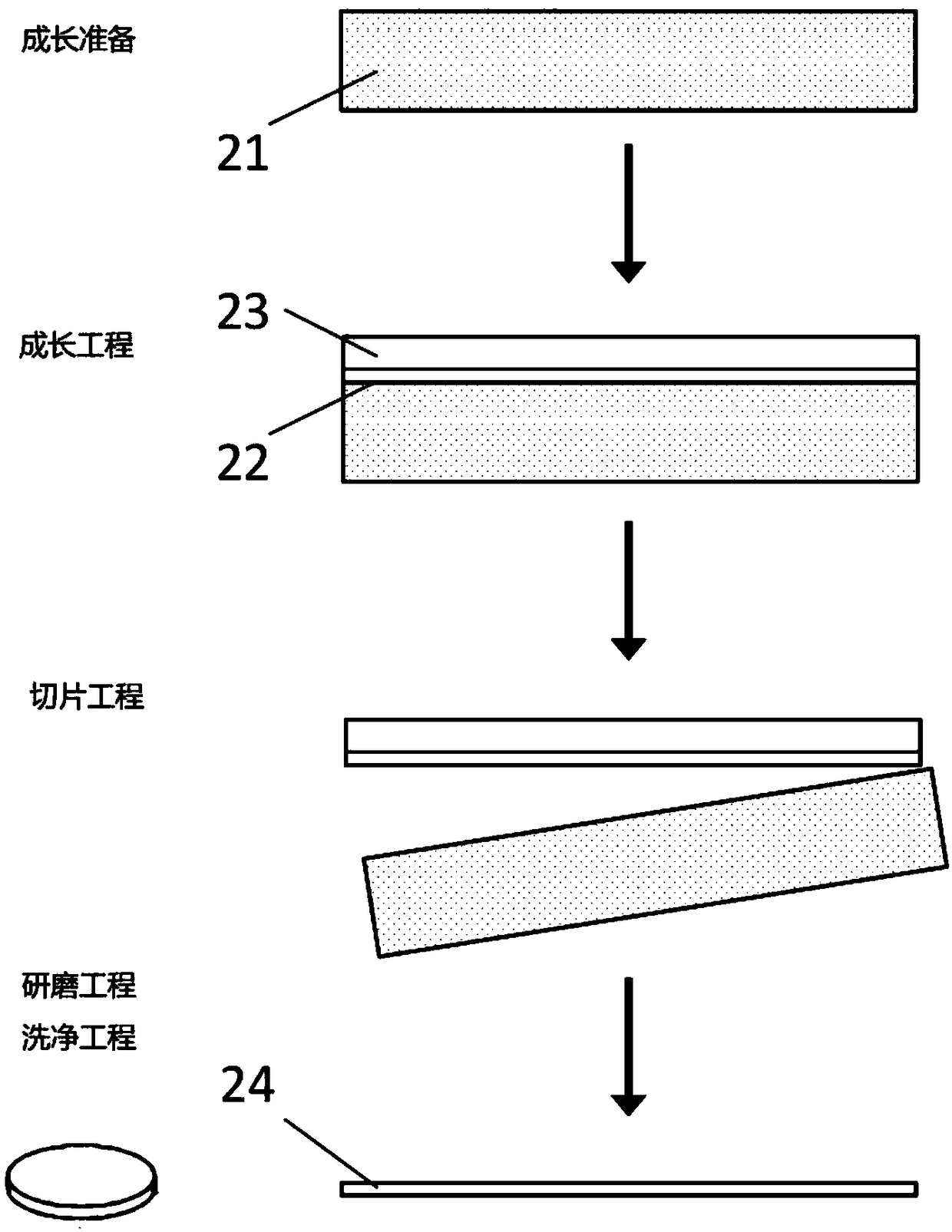

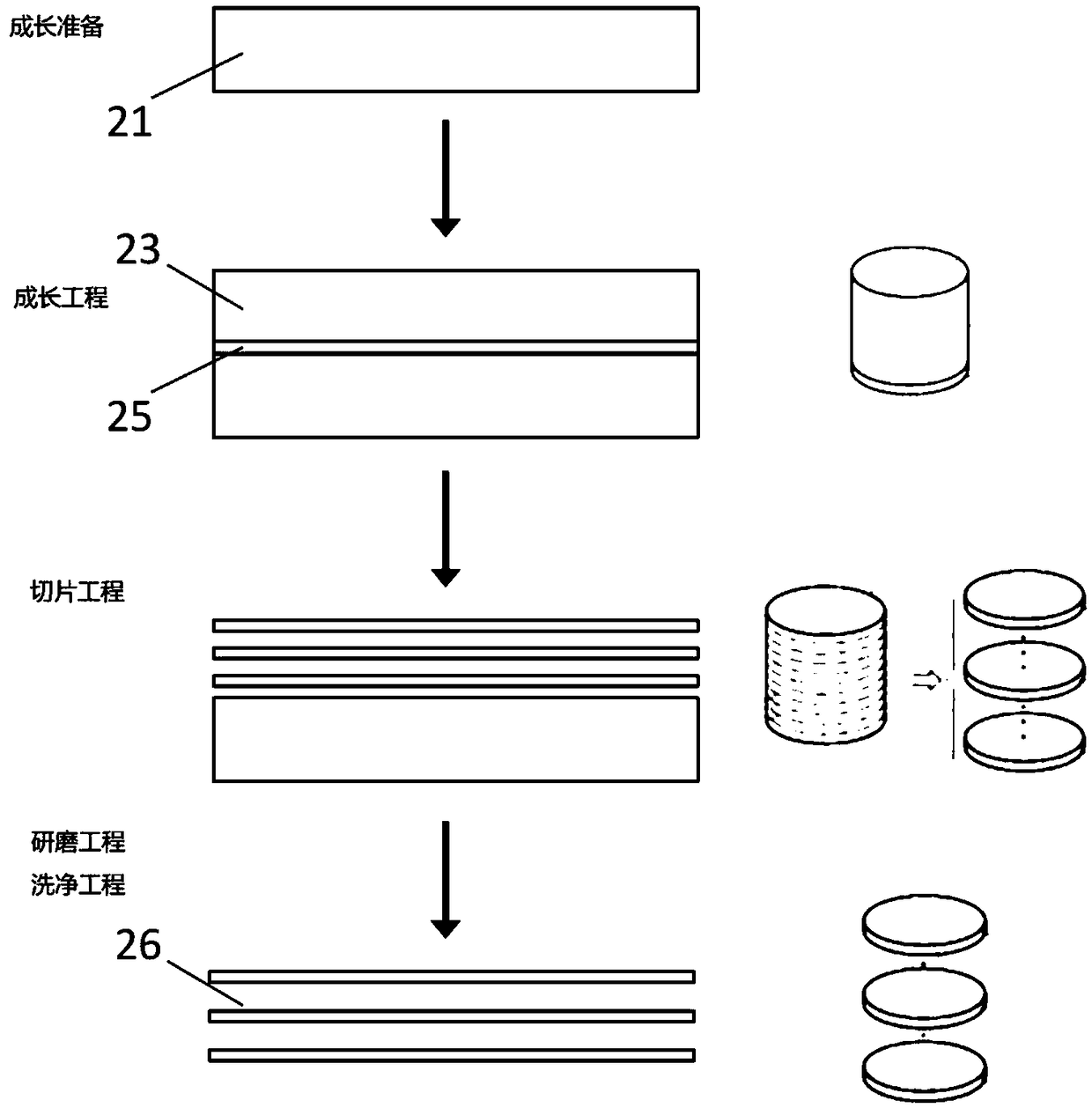

Method for manufacturing gallium nitride single crystal wafer

InactiveCN109411329ANo dislocationNo crystal defectsSemiconductor/solid-state device manufacturingSingle crystalThermal expansion

The invention belongs to the manufacturing method, and particularly relates to a method for manufacturing a gallium nitride single crystal wafer. The method for manufacturing the gallium nitride single crystal wafer comprises the following steps of carrying out crystallizing of gallium nitride by using an HVPE two-stage growth method on an (ScAlMgO4) substrate. The method has the remarkable effects that the maximum characteristic of the GaN crystallizing is embodied in the crystal quality and the size of the wafer. In the invention, the lattice constant and the thermal expansion coefficient ofthe GaN substrate are basically consistent with those of an SCAM substrate, so that the manufacturing of the high-quality GaN crystal without dislocation and crystallization defects can be realized.

Owner:WUXI WUYUE SEMICON CO LTD

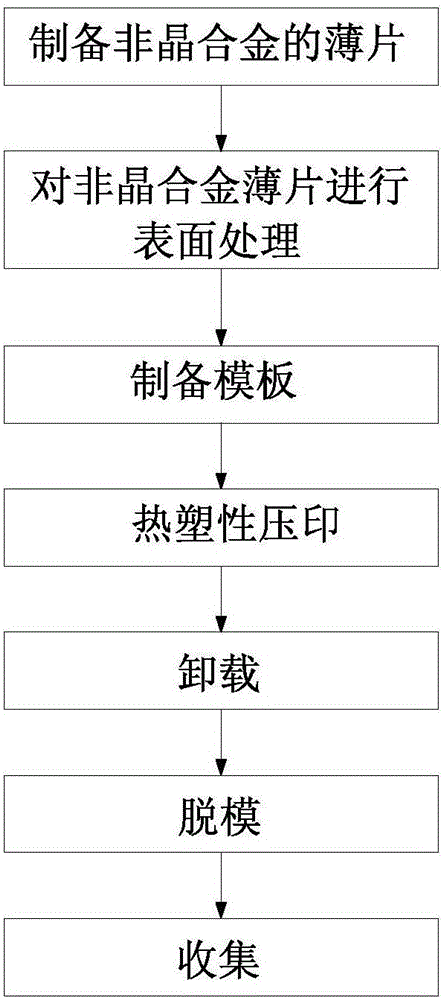

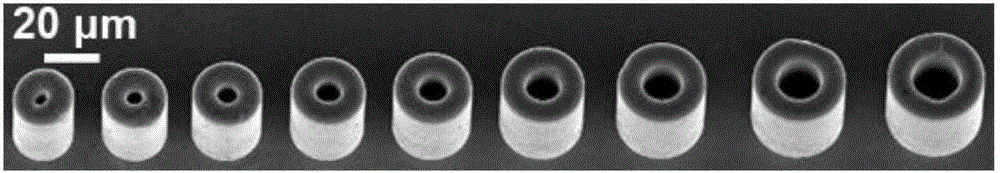

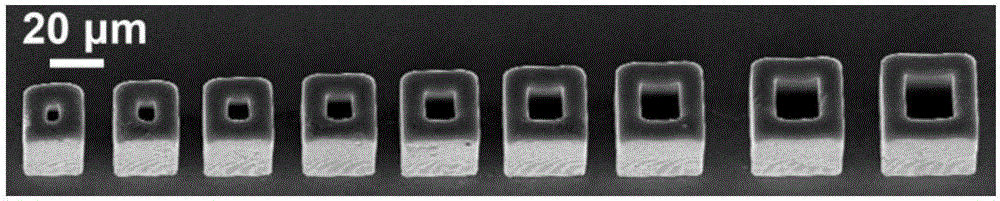

Preparation method of amorphous alloy-based metal micrometer tube

InactiveCN106276782AWell-thought-outReasonable designDecorative surface effectsChemical vapor deposition coatingMicrometerAlloy thin film

The invention discloses a preparation method of an amorphous alloy-based metal micrometer tube. The preparation method comprises the following steps: (1) preparing an amorphous alloy thin film; (2) performing surface treatment on the amorphous alloy thin film; (3) preparing a template; (4) folding the surface, subjected to the surface treatment, of the amorphous alloy thin film with the template, and performing thermoplastic embossing; (5) performing unloading: taking down the template and amorphous alloy when the surface of amorphous alloy is attached to the template, and forming a metal micrometer tube structure corresponding to the template; (6) performing demolding: separating amorphous alloy from the template; (7) collecting to obtain the metal micrometer tube. The preparation method is easy to operate, high in forming efficiency, and low in time consumption and cost; the prepared metal micrometer tube has the advantages of high precision, high structural controllability, high intensity, high corrosion resistance and high wear resistance performance; therefore, the preparation method has extremely high application value and is very suitable for being popularized.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

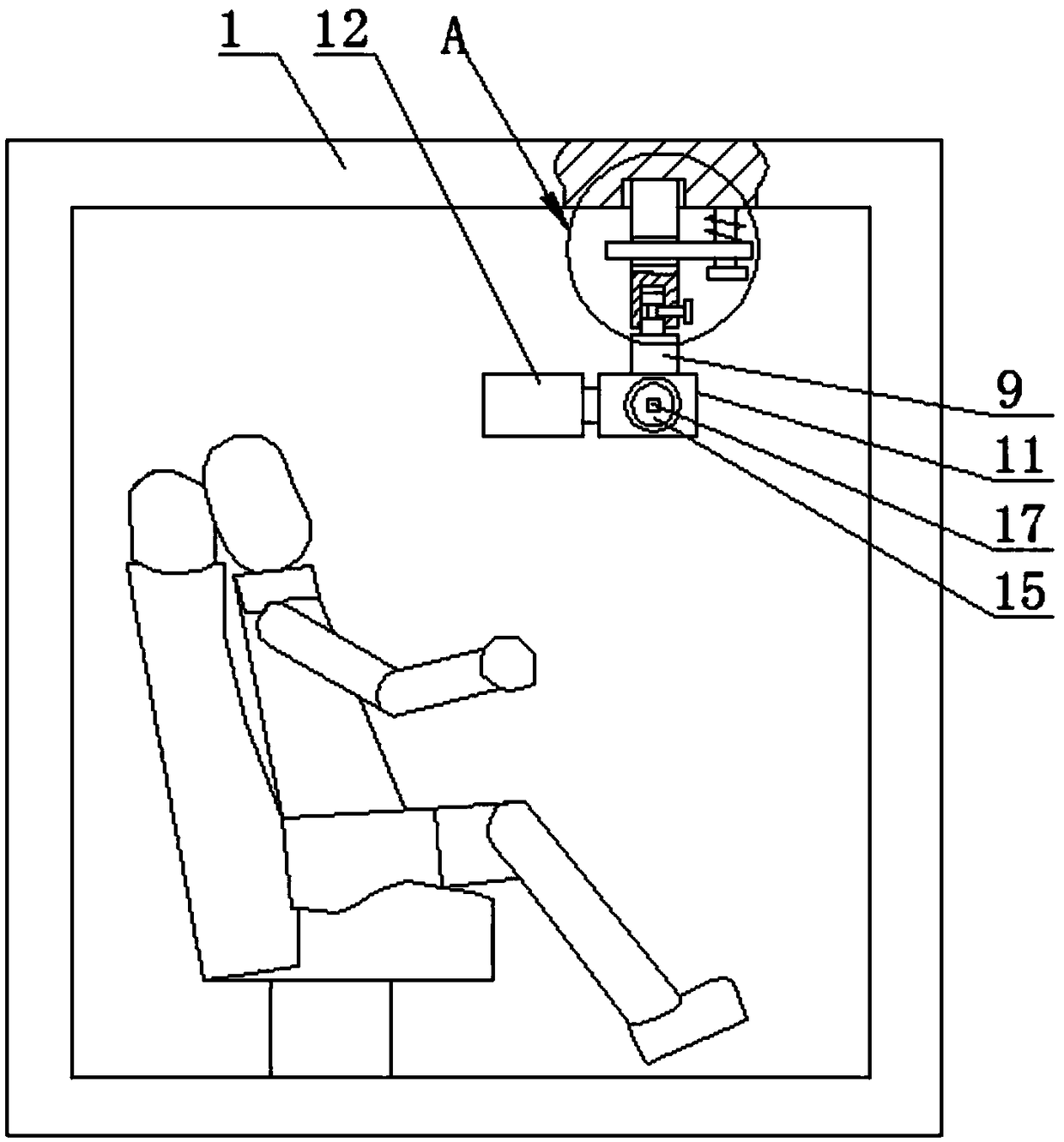

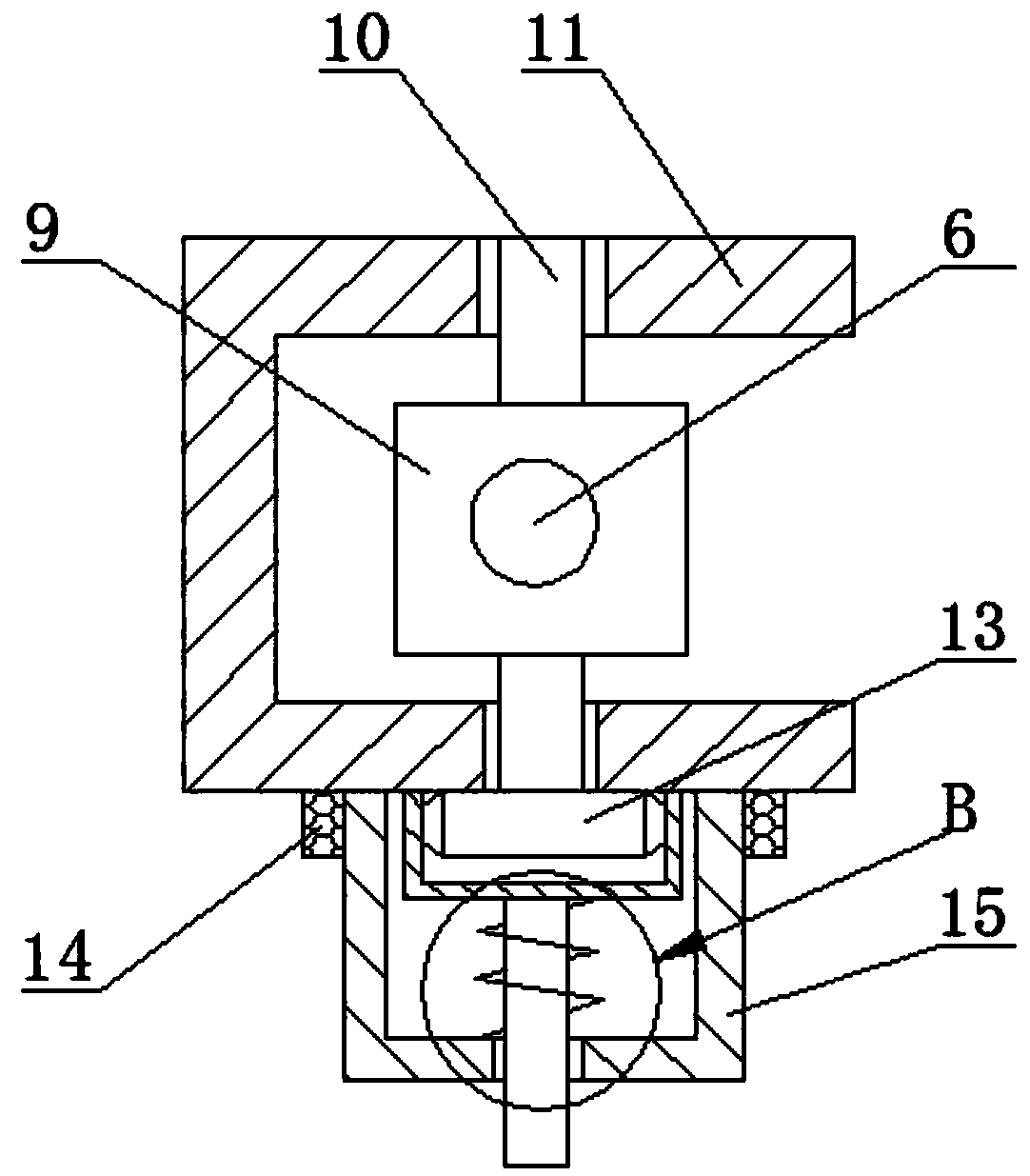

Portal crane operator fatigue monitoring and early warning device

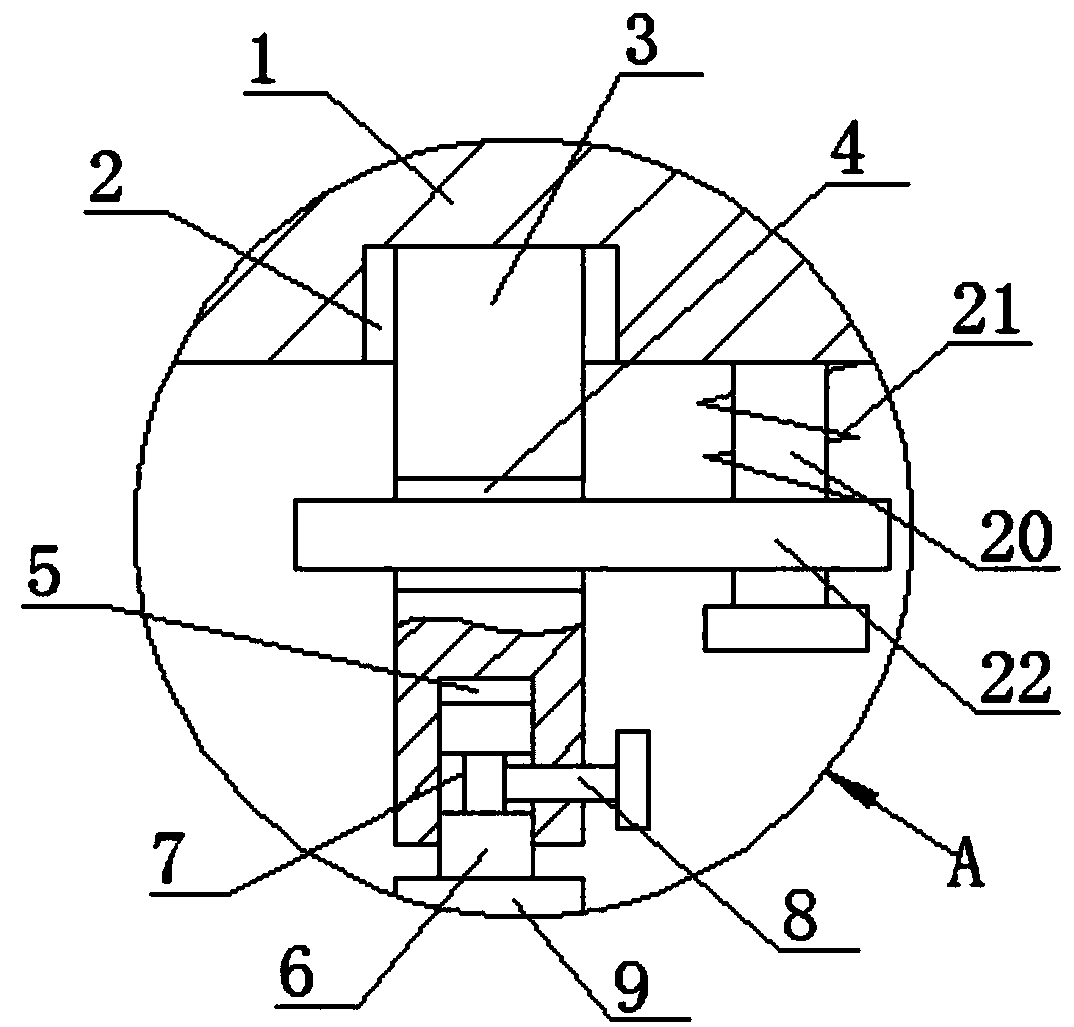

InactiveCN109205471AEasy to installAngle adjustment is stable and reliableSafety gearClamp connectionGear wheel

The invention discloses a portal crane operator fatigue monitoring and early warning device. The device comprises a portal crane, the portal crane is provided with a square groove, a supporting columnis in clamping connection with the interior of the square groove, the supporting column is provided with a circular groove, the interior of the circular groove is rotatably sleeved with a cylinder, aconnection rod is fixedly connected with the lower end of the cylinder, the interior of the connection rod is fixedly sleeved with a positioning shaft, the outer side of the positioning shaft is rotatably sleeved with a shaft seat, and a camera is fixedly connected with the left end of the shaft seat; and a gear is fixedly connected with the tail end of the positioning shaft, a supporting sleeveis fixedly connected with the surface of the shaft seat, a cylinder body is connected with the interior of the supporting sleeve through a thread, the cylinder body is provided with a limiting groove,the interior of the limiting groove is slidably sleeved with a square rod, and a clamping sleeve is fixedly connected with the tail end of the square rod. The camera of the portal crane operator fatigue monitoring and early warning device is convenient to install, the angle can be adjusted stably and reliably, and the phenomenon of dislocation cannot occur.

Owner:青岛港湾职业技术学院

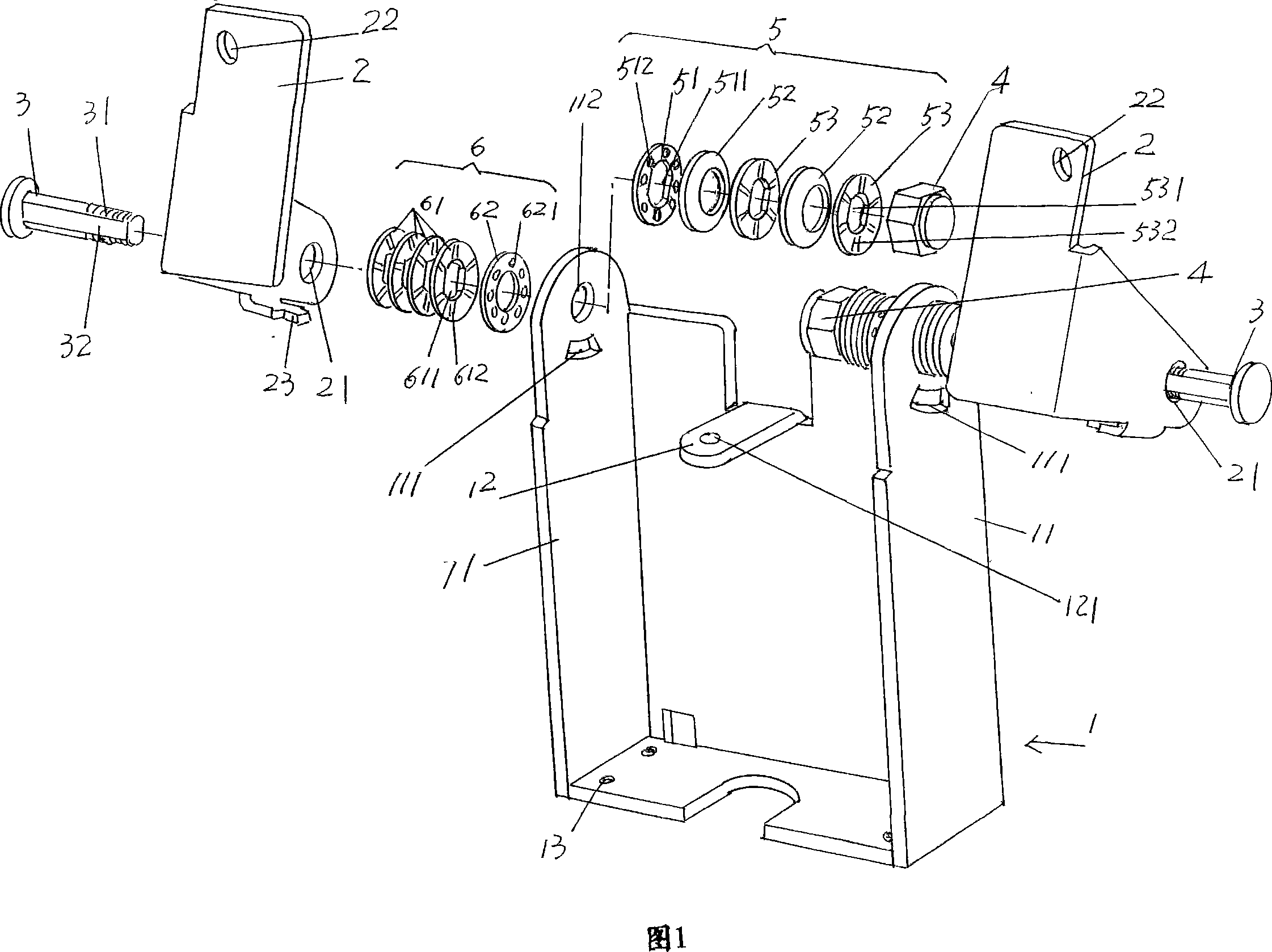

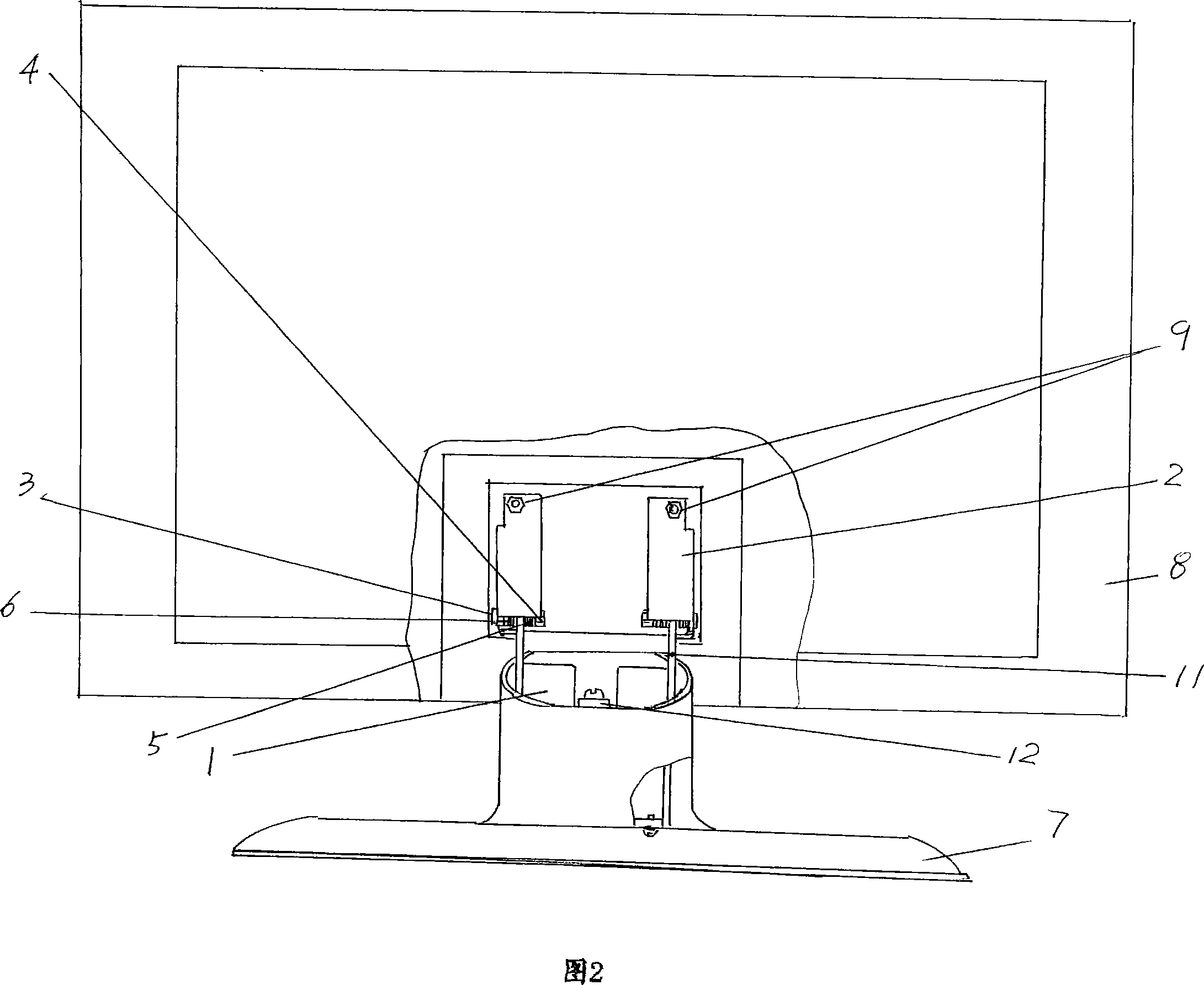

Rotary shaft rack for liquid crystal display screen

InactiveCN101051531AReduce the numberGuaranteed neutralityInstrument housingStands/trestlesLiquid-crystal displayEngineering

The present invention relates to a spindle support for supporting and fixing liquid crystal display screen, belonging to a transition device between the display screen and display screen base seat. Said spindle support includes the following several portions: a first fixing component, a pair of second fixing components a pair of interconnecting components, and elastic positioning device and an alignment regulation device. Said invention also provides the concrete structure of above-mentioned every portion.

Owner:江苏新华明机械制造实业有限公司

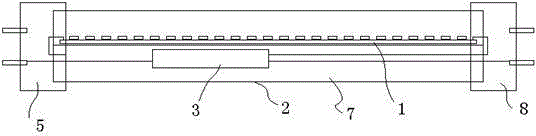

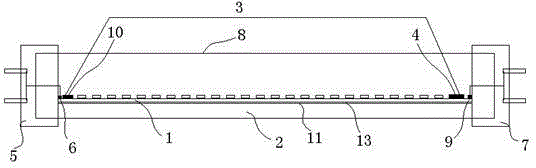

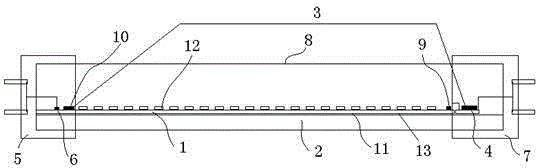

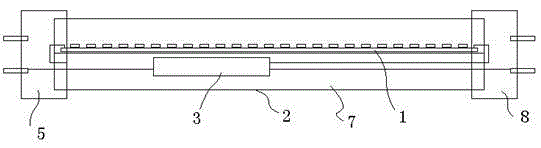

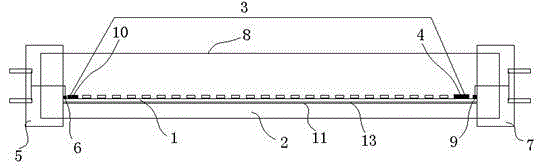

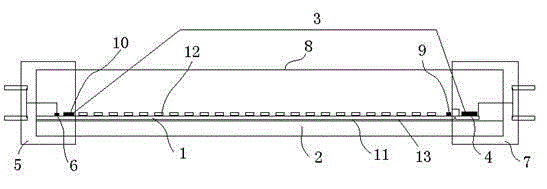

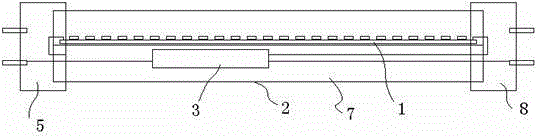

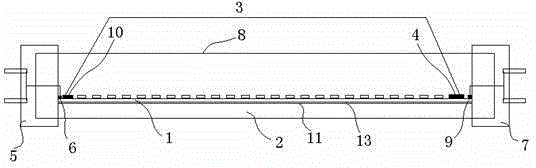

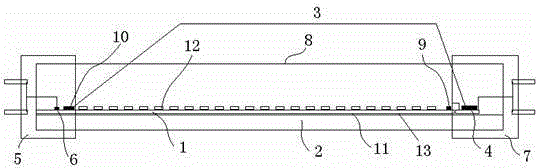

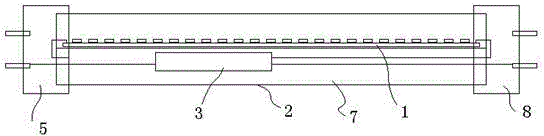

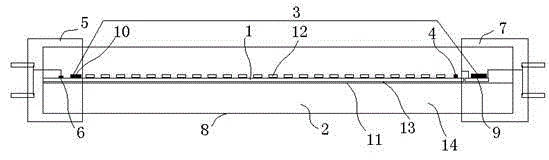

LED tubing lamp structure

InactiveCN104456218AFirmly connectedEasy to assemblePoint-like light sourceElectric circuit arrangementsElectricityAlternating current

The invention relates to an LED tubing lamp structure comprising a lamp panel, a lamp panel holder and a power supply. A rectification IC (integrated circuit) in the power supply is arranged at one end of the lamp panel, a constant current circuit in the power supply is arranged at the other end of the lamp panel, and lamp beads are arranged between the rectification IC and the constant current circuit; the rectification IC and the lamp beads are welded on the lamp panel and distributed along the lengthwise direction of the lamp panel carrier; a non-welding surface of the lamp panel is connected with a plane surface of the lamp panel holder in a heat conduction manner; the alternating-current input end of the rectification IC is provided with a first alternating-current bonding pad close to a first lamp cap, and the first alternating-current bonding pad is electrically connected with the connection end of the first lamp cap; the other alternating-current input end of the rectification IC is routed to the other end of the lamp panel through the lamp panel to be close to a second alternating-current bonding pad of a second lamp cap, and the second alternating-current bonding pad is electrically connected with the connection end of the second lamp cap; the positive output of the rectification IC is electrically connected with one end of the LED lamp beads of the lamp panel; the other end of the LED lamp beads of the lamp panel is electrically connected with the positive input end of the constant current circuit, and the negative output end of the constant current circuit is connected with the negative output end of the rectification IC. The LED tubing lamp structure is good in structure and high in reliability.

Owner:XIAN XINWEI INFORMATION TECH

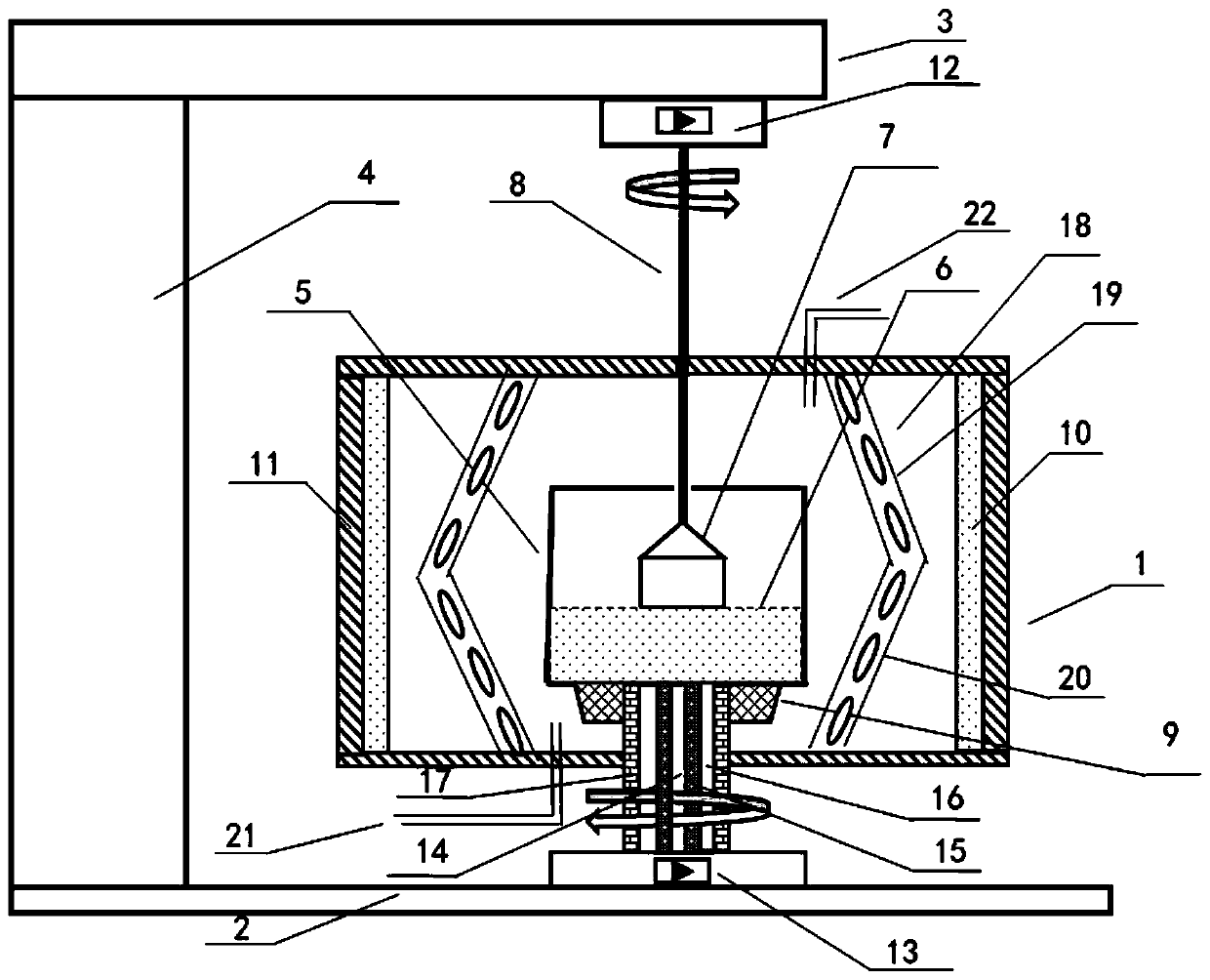

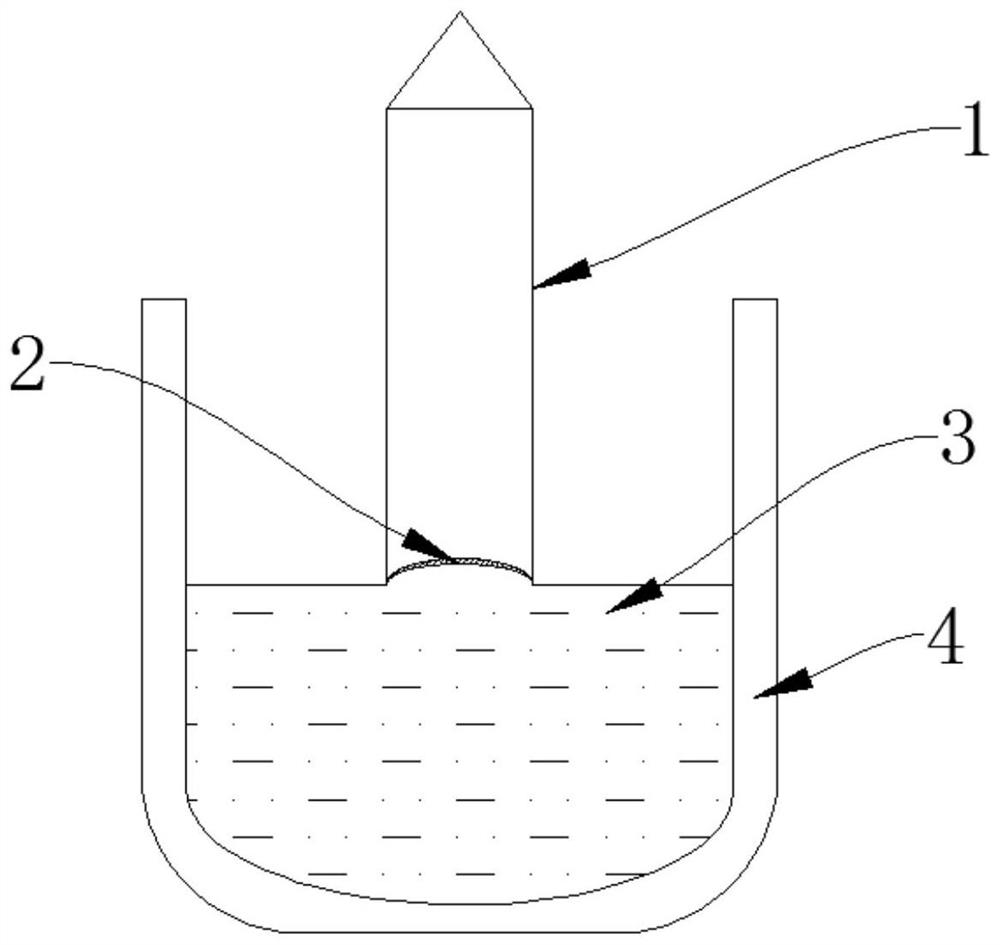

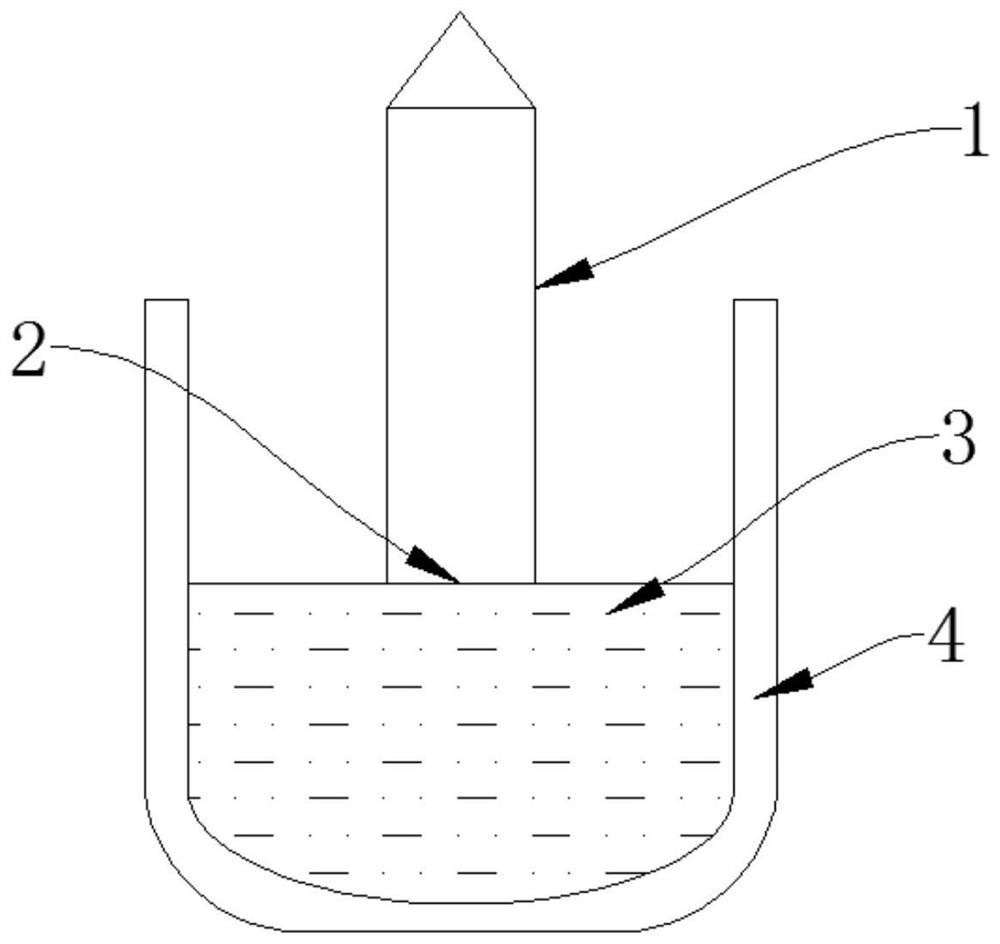

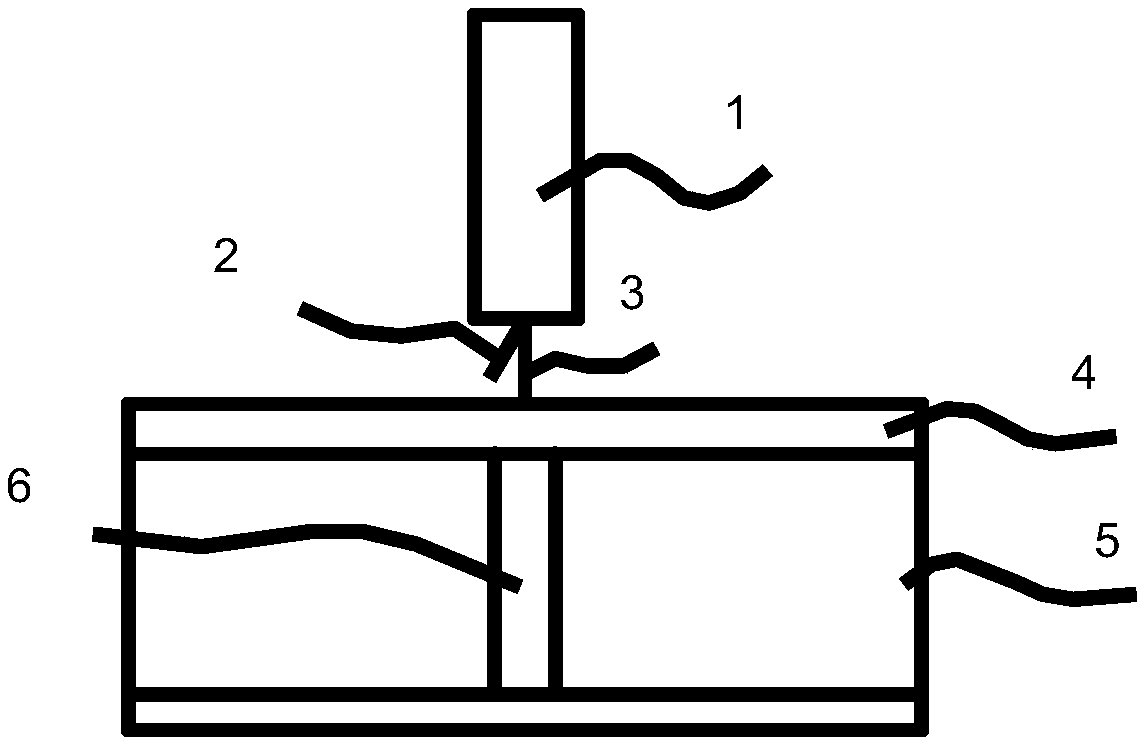

Device and method for preparing high-purity single crystal germanium by Czochralski method

PendingCN111074346APrecise control of temperature gradientsAvoid crackingPolycrystalline material growthBy pulling from meltCzochralski methodCrucible

The invention discloses a device and a method for preparing single crystal germanium by a Czochralski method. The device comprises a germanium single crystal growth furnace, wherein a crucible is arranged in a cavity of the furnace; a heating device is arranged around crucible, wherein the cross section of the heating device in the single crystal pulling direction is of a symmetrical structure like a pair of round brackets, so that the crucible is enclosed by the heating device; the heating device is divided into an upper heater and a lower heater, wherein the included angle between the upperheater and the lower heater is 110-160 degrees, and a plurality of high-frequency eddy current induction coils which are uniformly distributed from top to bottom are arranged in the upper heater andthe lower heater so as to control the axial and radial gradients of a temperature field around a single crystal. The device disclosed by the invention can be used for regulating and controlling the preparation process of single crystal germanium according to production requirements, and has extremely high operation flexibility and automation potential. The prepared crystal is good in crystallization property, free of defects such as cracking, dislocation, bubbles, inclusions and scattering and high in single crystal repetition rate, and a good crystal growth effect is achieved.

Owner:CENT SOUTH UNIV

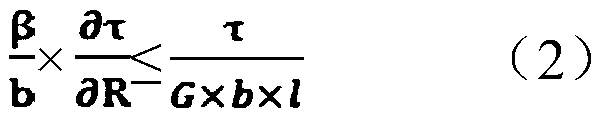

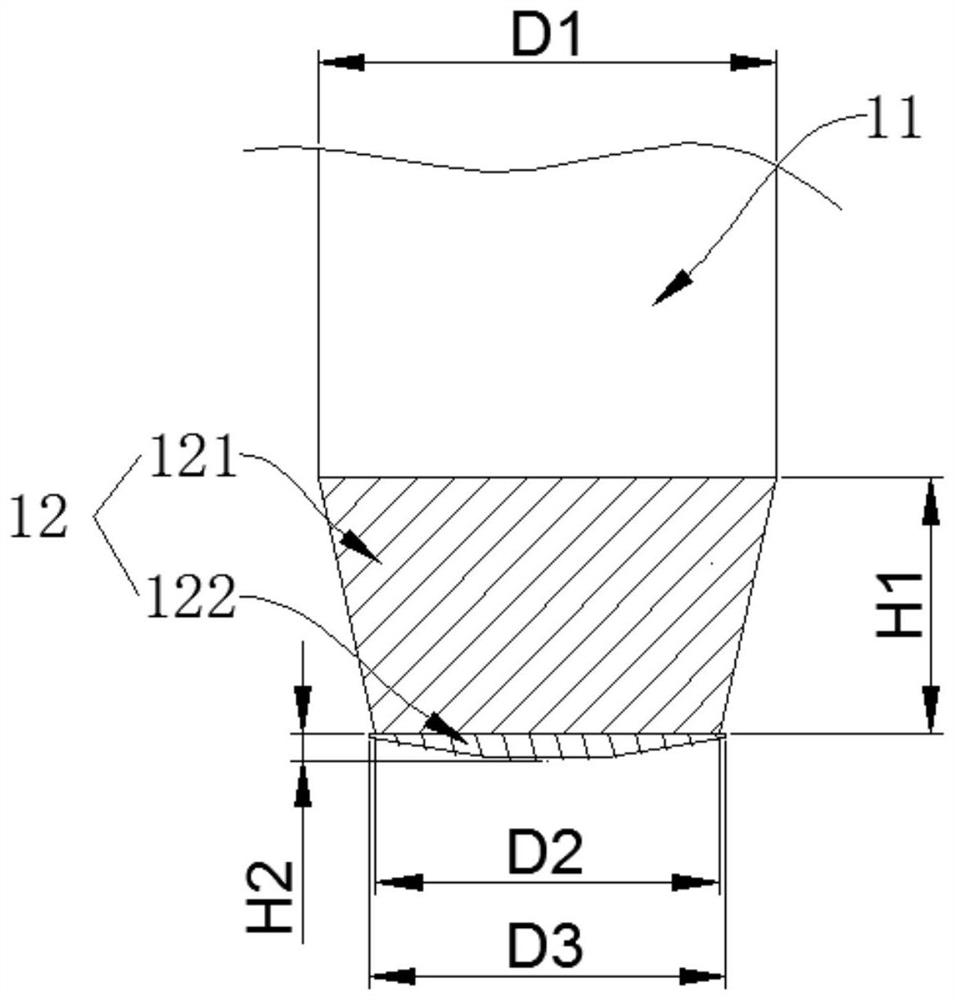

Large-size single crystal segment-taking ending structure and control method thereof

PendingCN112301415ASolve the technical problem of low production efficiency in closing controlHigh applicability and controllabilityPolycrystalline material growthBy pulling from meltEngineeringSingle crystal

The invention provides a large-size single crystal segment-taking ending structure which comprises an upper segment part and a lower segment part integrally connected with the upper segment part. Theupper segment part is higher than the lower segment part, and the maximum diameter of the upper segment part is the same as the diameter of a crystal equal-diameter segment. The maximum diameter of the lower segment part is larger than the minimum diameter of the upper segment part and smaller than the maximum diameter of the upper segment part. The maximum height of the lower segment part is located between the minimum heights of the two sides, and a variable curved surface is arranged between the minimum height and the maximum height. The segment-taking ending structure provided by the invention is a novel ending structure, is particularly suitable for ending large-size single crystal crystals, solves the technical problem of low ending control production efficiency in the prior art, andis high in universality and controllable. The invention further provides a control method of the large-size single crystal segment-taking ending structure, segment-taking ending can be conducted on asingle crystal with the diameter of 240-310 mm within 1-1.5 h, an ending structure which is ended but not sharpened is obtained, the working hours are shortened, dislocation is eliminated, the quality of the single crystal is guaranteed, the production efficiency is improved, and the production cost is reduced.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

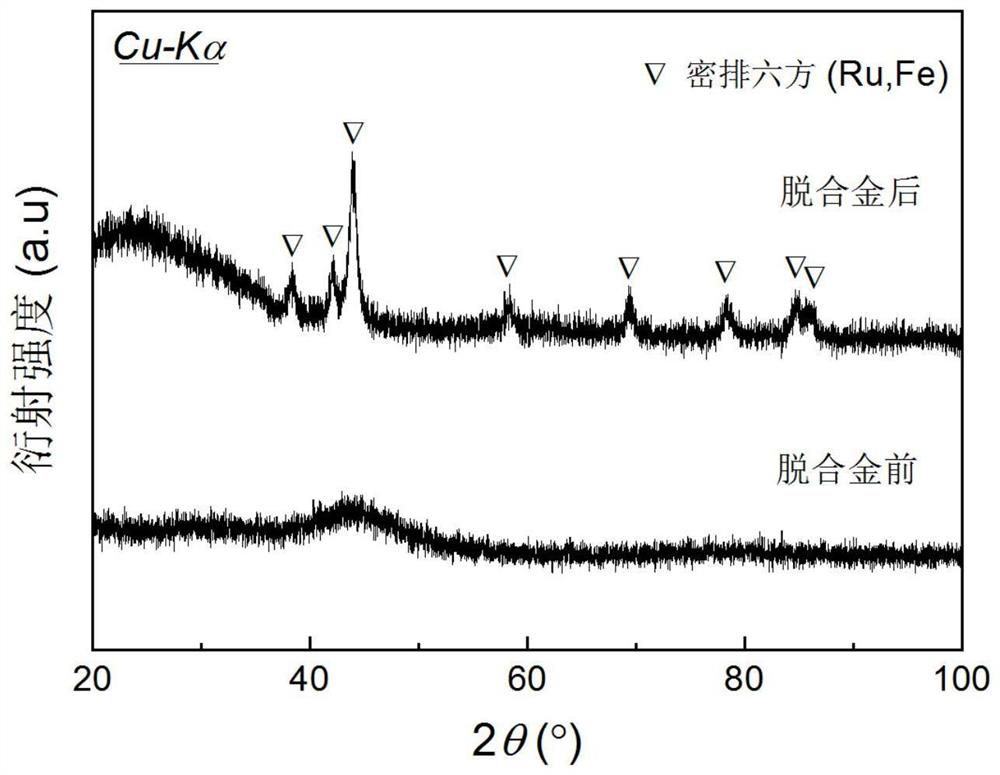

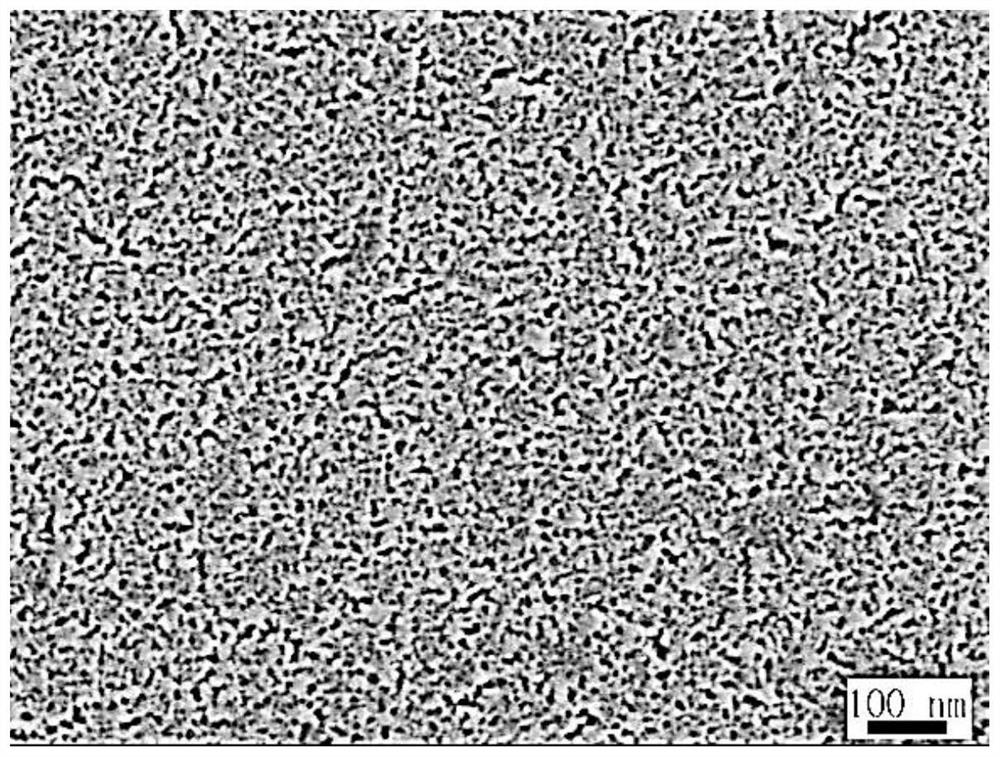

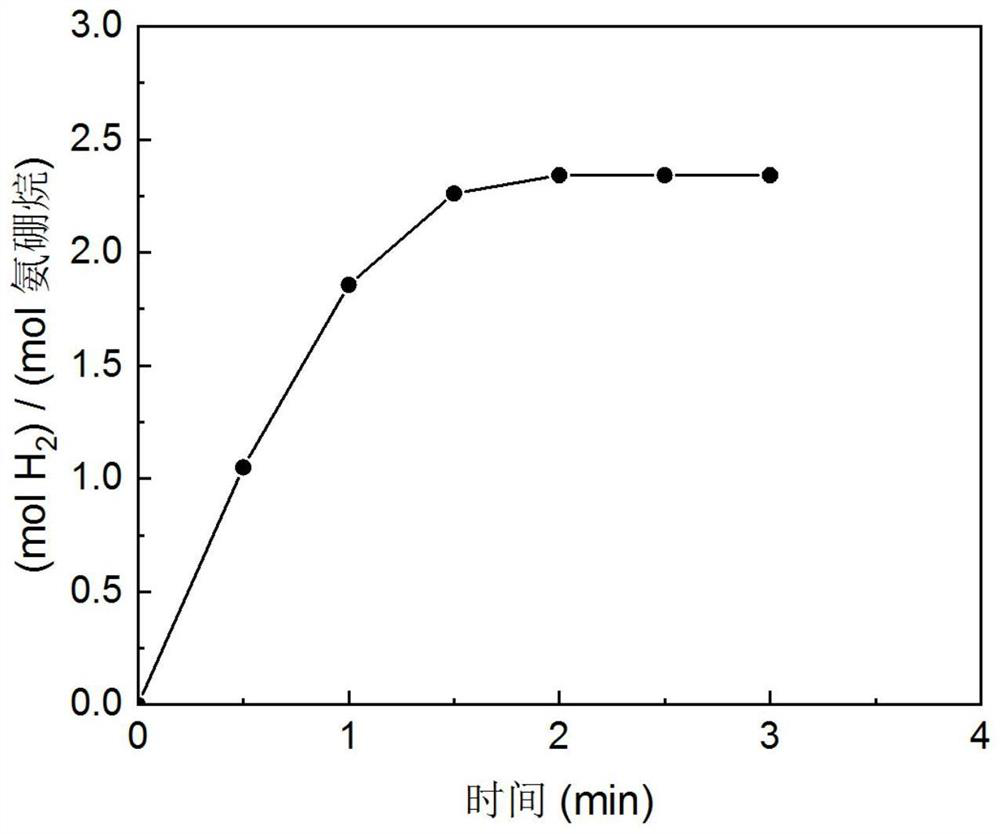

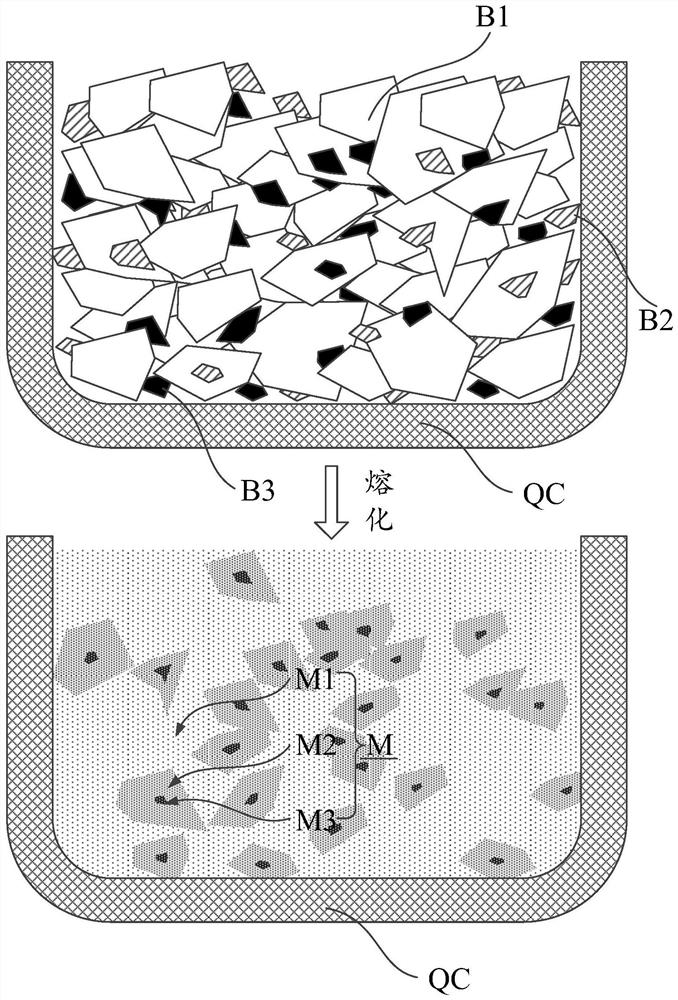

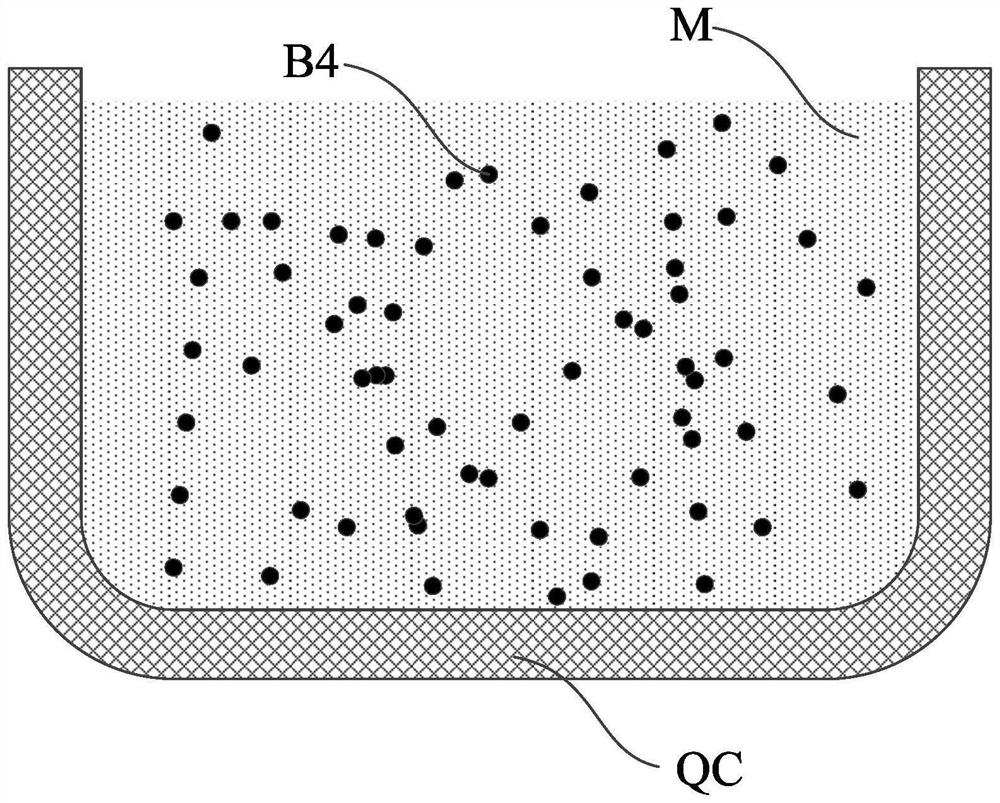

Preparation method of nano-porous Ru-Fe-Co alloy with high ammonia borane hydrolysis hydrogen production catalytic activity

PendingCN113522312ASimple processShort processCatalyst activation/preparationHydrogen productionPtru catalystMetallurgy

The invention provides a preparation method of a nano-porous Ru-Fe-Co alloy with high ammonia borane hydrolysis hydrogen production catalytic activity. The preparation method comprises the following steps: preparing a Fe-Co-Ru-B amorphous alloy strip precursor by adopting a single-roller melt-spinning method; and carrying out dealloying on the precursor through a chemical or electrochemical process in an acid environment of 25-80 DEG C to prepare the nano-porous Ru-Fe-Co alloy which is composed of a single close-packed hexagonal phase and has an average pore size of 5-11 nm and a pore wall size of 10-20 nm. The method is simple in process, short in flow, efficient and energy-saving, the pore size of the nano-porous alloy can be regulated and controlled, and the Ru-Fe-Co nano-porous alloy obtained by combining the high specific surface area characteristic of the nano-porous structure and the dual-function effect between Ru-Fe and Co has high ammonia borane hydrolysis hydrogen production catalytic activity, and the catalyst has an application prospect in the field of ammonia borane hydrolysis hydrogen production catalysts.

Owner:DALIAN UNIV OF TECH

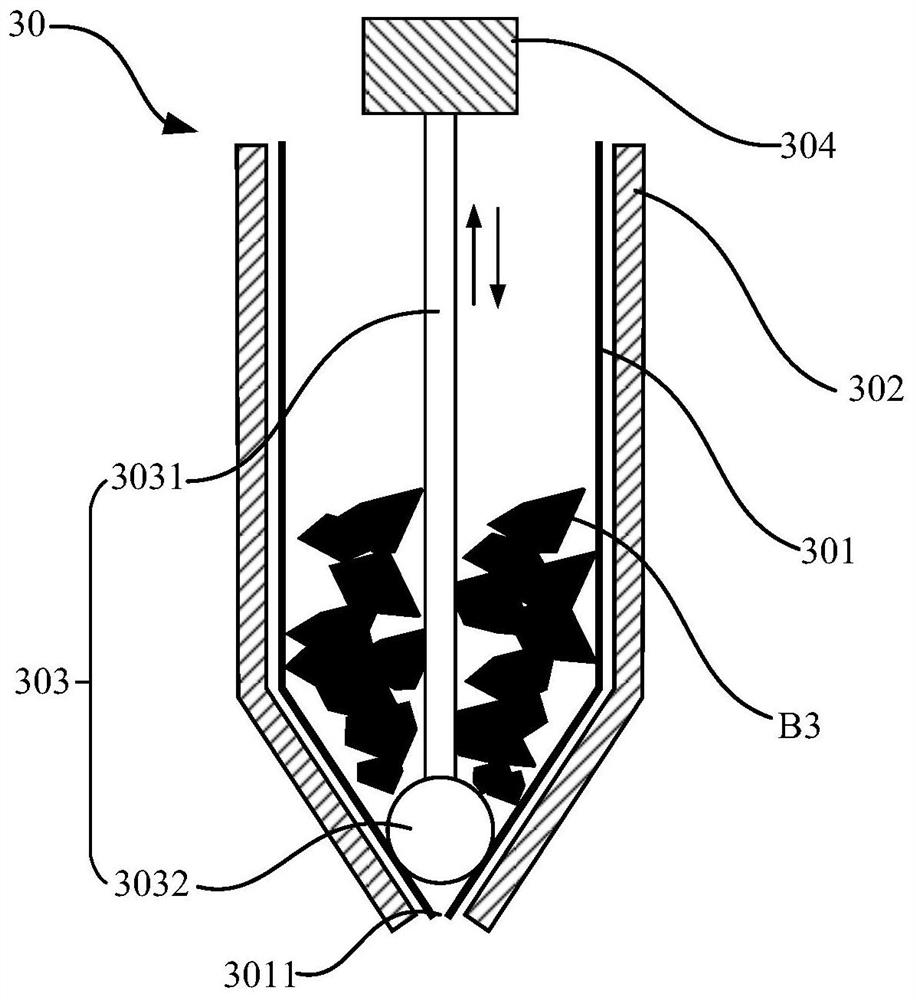

Nitrogen doping agent feeding device and method and manufacturing system of nitrogen-doped single crystal silicon rod

PendingCN113882015ANo dislocationPrevent fallingPolycrystalline material growthBy pulling from meltBoron atomSilicon nitride

The embodiment of the invention discloses a nitrogen doping agent feeding device and method and a manufacturing system of a nitrogen-doped single crystal silicon rod. The nitrogen doping agent feeding device comprises a bearing pipe with an opening formed in the bottom, wherein the bearing pipe is used for bearing silicon nitride to be molten; a heating device which surrounds the outer side of the bearing pipe and is used for heating the silicon nitride to be molten to enable the silicon nitride to be molten to be completely molten into a silicon nitride melt; a blocking device which is arranged in the bearing tube and can be attached to the bottom of the bearing tube to shield the opening, so that the silicon nitride to be molten is prevented from falling into the quartz crucible from the opening; a gap can be formed between the blocking device and the bottom of the bearing pipe to open the opening, so that the silicon nitride melt drops into the quartz crucible bearing the silicon melt containing boron atoms from the opening; and a lifting mechanism which is used for lifting or descending the blocking device.

Owner:西安奕斯伟材料科技股份有限公司

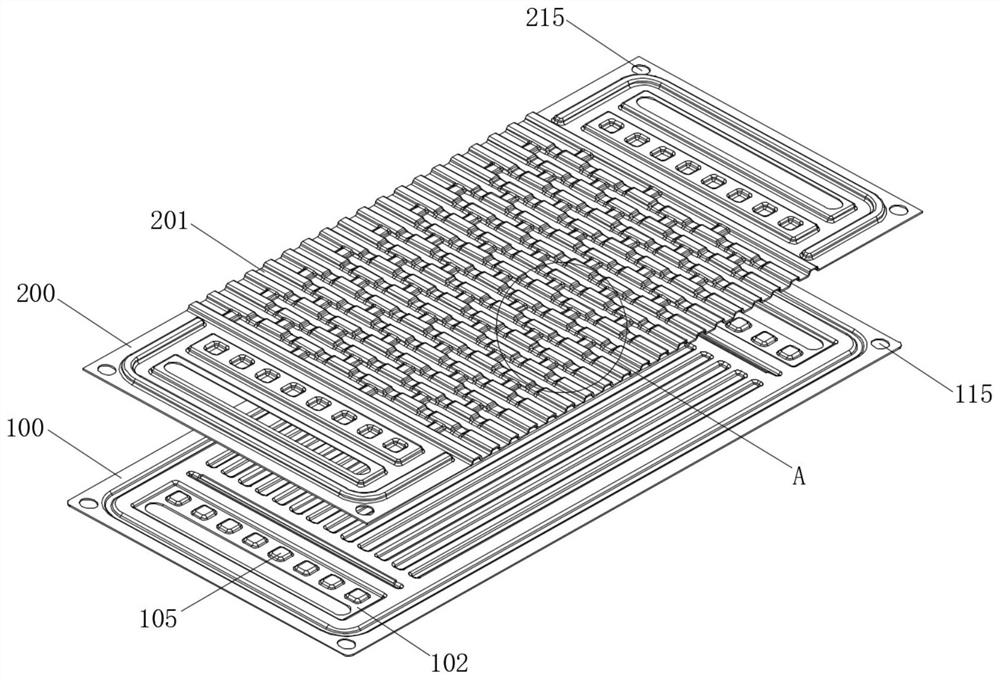

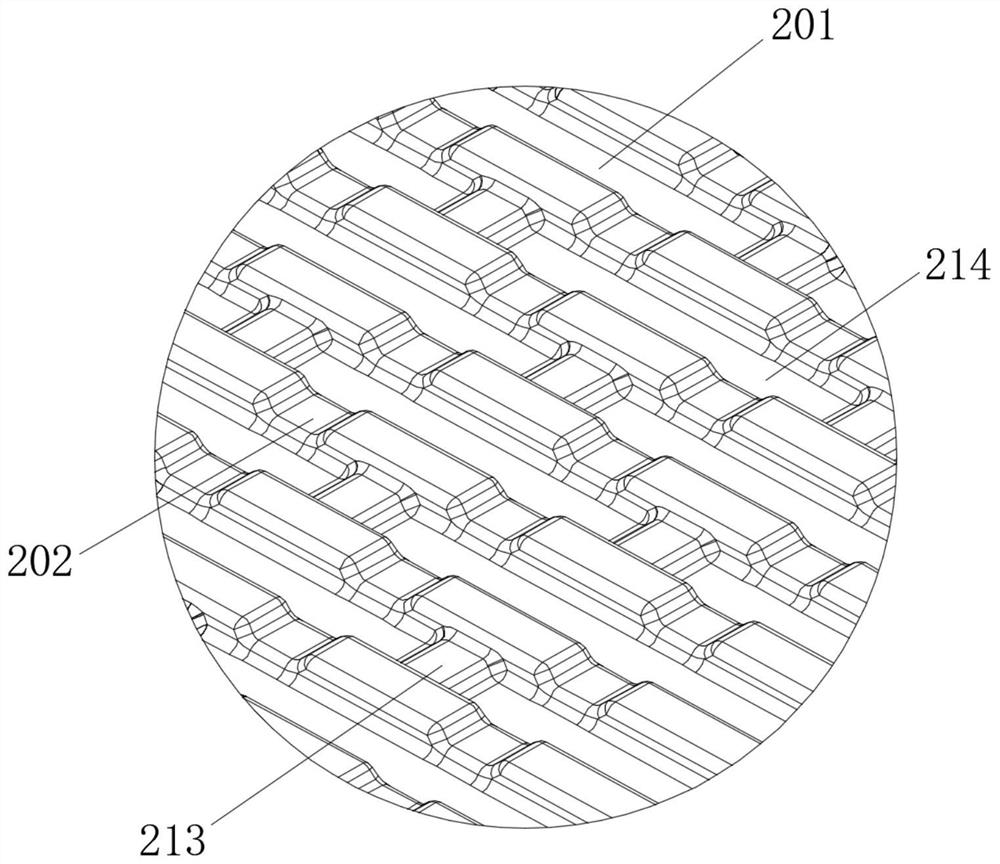

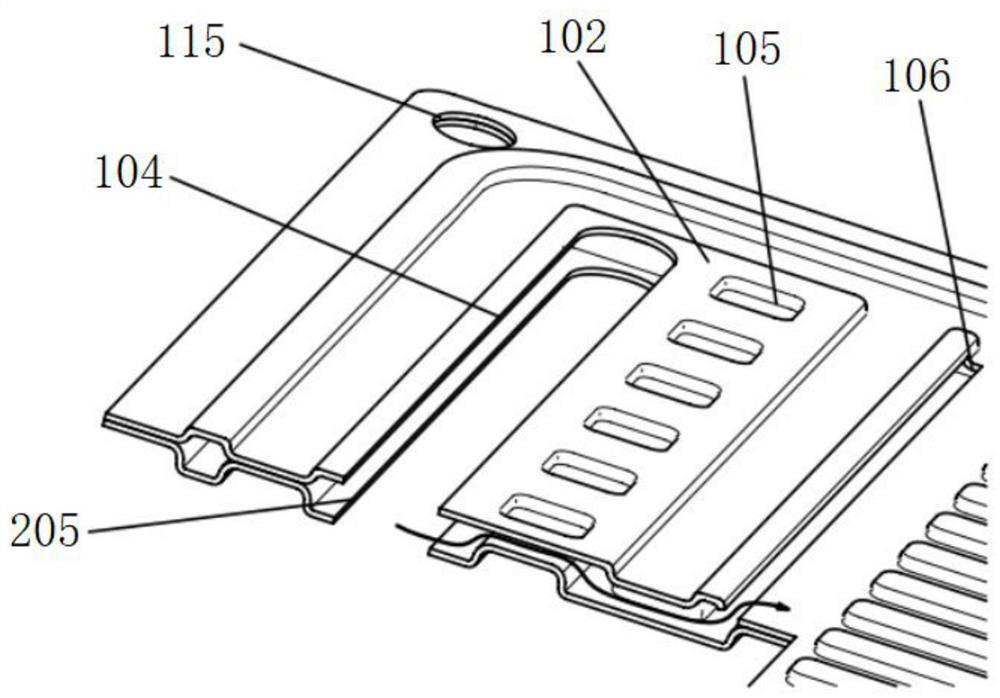

Air-cooled fuel cell stack and metal bipolar plate thereof

PendingCN114583204AReduce volumeImprove power densityFuel cell heat exchangeFinal product manufactureFuel cellsMaterials science

The invention discloses an air-cooled fuel cell metal bipolar plate which comprises an anode plate and a cathode plate which are fixedly connected in a laminated manner, the opposite surfaces of the anode plate and the cathode plate are reaction gas circulation surfaces, and the opposite surfaces of the anode plate and the cathode plate are cooling surfaces; a plurality of fuel gas first flow channels extending in the length direction of the anode plate are arranged on the reaction gas flow surface of the anode plate in parallel; a plurality of second fuel gas flow channels extending in the width direction of the cathode plate are arranged on the reaction gas flow surface of the cathode plate in parallel; a plurality of diffusion grooves communicated with the two adjacent fuel gas second flow channels are formed between the two adjacent fuel gas second flow channels; a plurality of cooling gas flow channels extending in the width direction of the cathode plate are arranged on the cooling surface of the cathode plate in parallel; and the cooling gas flow channels and the second fuel gas flow channels are arranged at intervals and penetrate through the two sides of the cathode plate in the width direction. The assembly and preparation difficulty is low, the oxygen concentration under the bipolar plate ridge can be effectively improved, and the hydrothermal distribution in the fuel cell is improved.

Owner:YOUON TECH CO LTD

Hydraulic locking mechanism for oil storage tank of oil tank truck

InactiveCN107776467AImprove installation stabilityImprove sturdinessTank vehiclesItem transportation vehiclesTelescopic cylinderOperation safety

The invention discloses a hydraulic locking mechanism for an oil storage tank of an oil tanker, which comprises a clamping plate, a clamping plate is arranged on the top of the clamping plate, a clamping groove is opened on the top of the clamping plate, and the clamping plate A positioning pin is arranged on one side of the groove, an oil guide pipe is arranged inside the clamping plate, an oil distribution pipe is arranged inside the oil guide pipe, an oil spray nozzle is arranged inside the oil guide pipe, and a return chamber is arranged on the top of the oil guide pipe. The inner and outer walls of the clamping plate are provided with a hollow plate, and the inside of the hollow plate is provided with balls, and the inner bottom of the clamping plate is provided with a telescopic cylinder, and the telescopic cylinder is connected with a hydraulic locking rod through a hydraulic telescopic rod. The bottom of the holding plate is welded with a bottom plate, the inner surface of the bottom plate is provided with positioning grooves, the two sides of the bottom plate are provided with anti-collision bars, and the outer side of the clamping plate is provided with reinforcing blocks. In the present invention, the overall structural design of the locking mechanism is simple and reasonable, the operation is safe and flexible, no loosening occurs after locking, and it has strong practicability.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Guidance system for hip replacement and method of use thereof

ActiveCN105012054BShorten completion timeShorten operation timeJoint implantsAcetabular componentCompletion time

The invention discloses a guide system for hip replacement and a using method thereof. The guide system comprises a handle, a guide connecting rod, an acetabular cup connector and a sleeve. The lower end of the handle is connected with the acetabular cup connector. One end of the guide connecting rod is connected with the side close to the upper end of the handle, a sleeve hole is formed in the other end of the guide connecting rod, and the sleeve is nested into the sleeve hole. The acetabular cup connector comprises a mounting shaft which can be connected with an acetabular cup in a rotating mode, and the center axis of the sleeve is roughly overlapped with the axis of the mounting shaft. According to the guide system for hip replacement and the using method thereof, the guide system is easy to assemble and disassemble and convenient, quick and accurate to use, the completion time of minimally invasive surgery is greatly shortened, any muscle and any joint capsule do not need to be cut off in the operation process, an acetabular component can be accurately positioned, inserted and pressed in a matched mode, and dislocation can be avoided.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

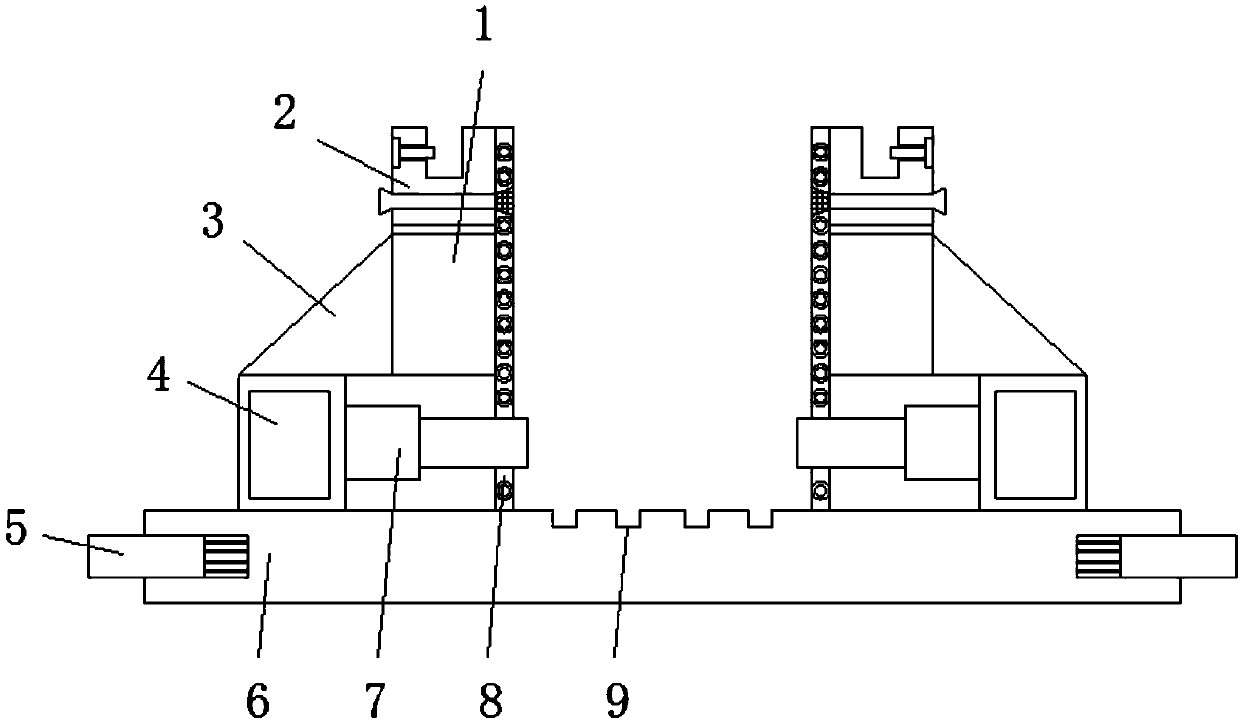

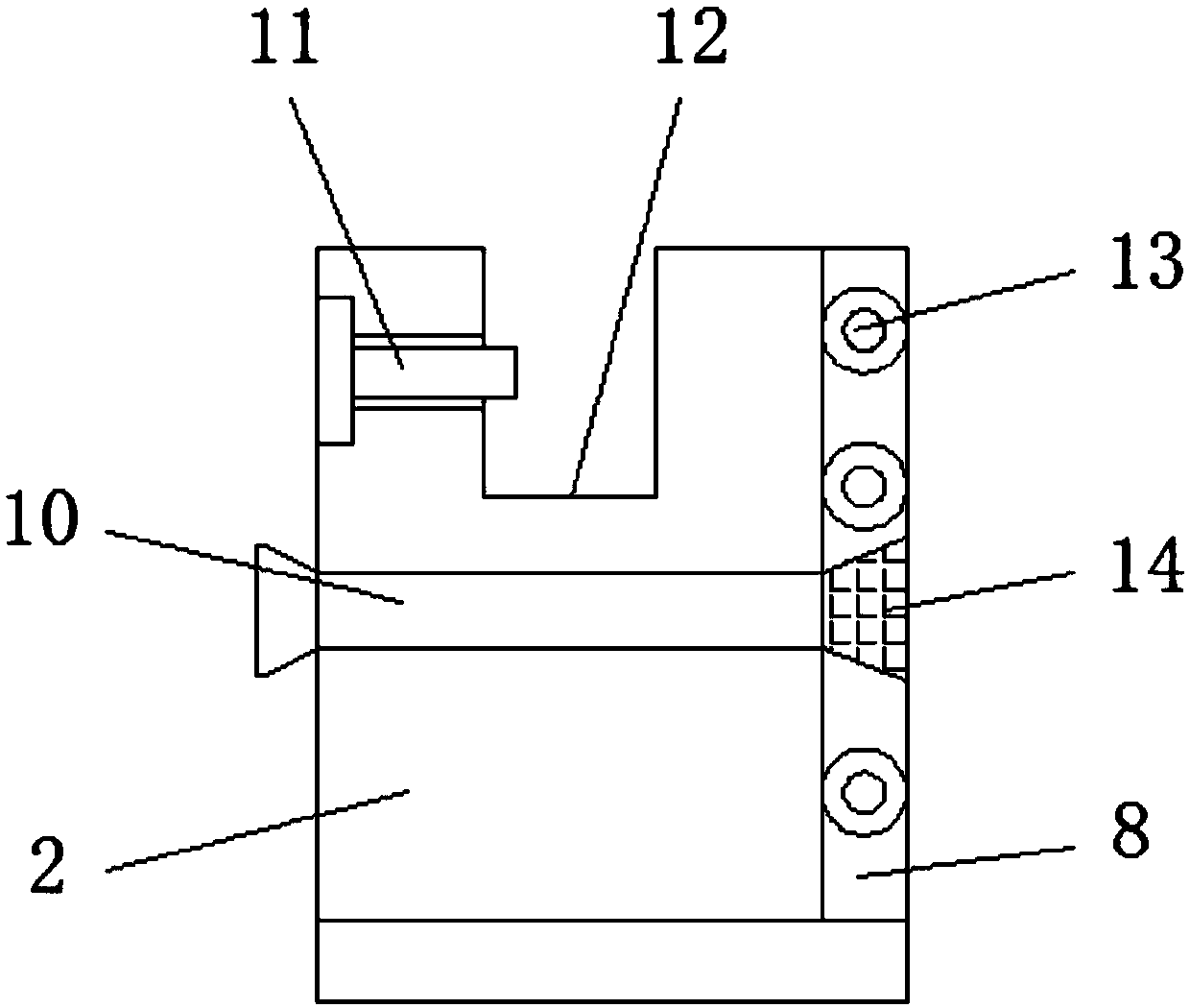

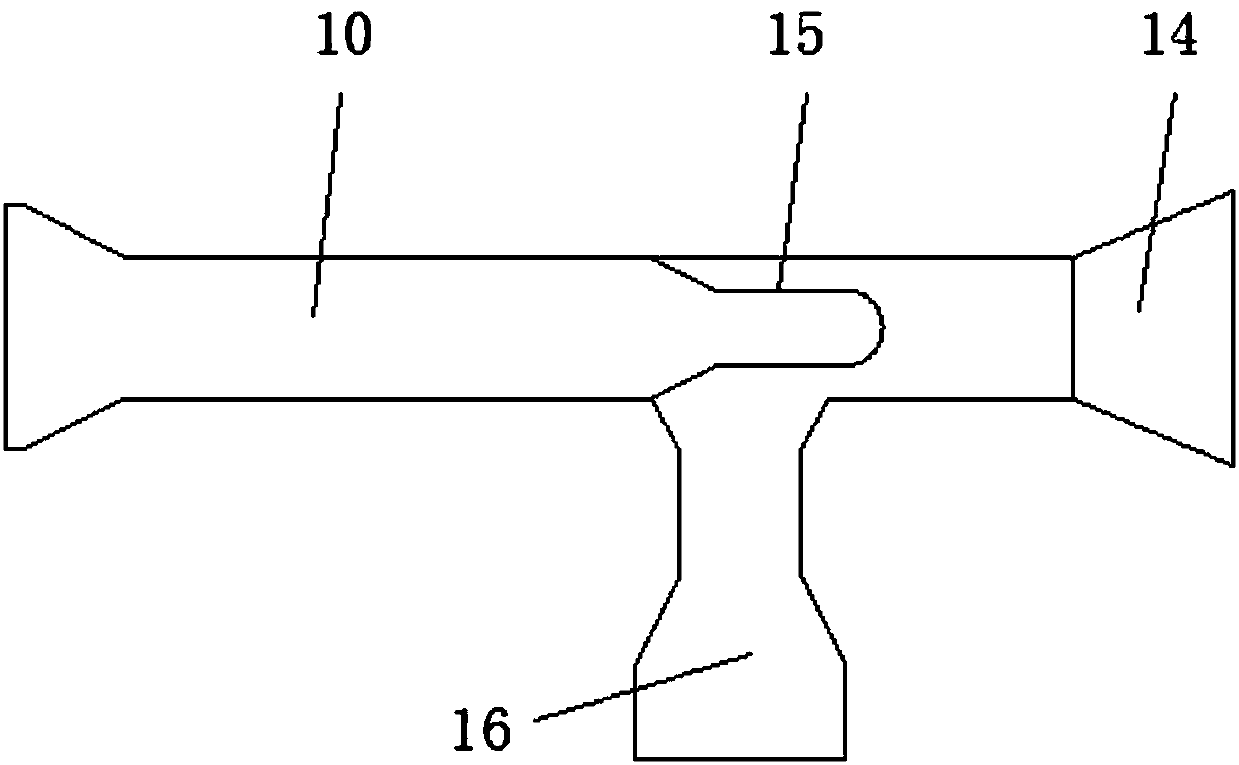

Roller lining installation positioning device and method

ActiveCN107838834APrecise positioningMeet the installation needsWork holdersMetal-working hand toolsDieselingStructural engineering

The invention discloses a roller lining installation positioning device and method. The device comprises a support, a positioning shaft, multiple guide keys and a pressing block. The support is supported on a diesel engine cam shaft corresponding cam base circle, the lower end of the positioning shaft is supported on the upper side of the support, one side of the positioning shaft is provided withan axially-through first guide groove, the multiple guide keys are axially overlapped in the lower end of the first guide groove, the middle of the positioning shaft is sleeved with a roller lining in a sliding mode, the upper end of the positioning shaft is sleeved with the pressing block in a sliding mode, and the pressing block presses the top of the roller lining. The structure is simple andcompact, assembly and disassembly are convenient, installation requirements of different specifications of roller linings can be met, and universality is high. The roller lining can be pressed in place only by pressing down the pressing block, operation and use are quite convenient, time and labor are saved, and the working efficiency is high. The roller lining is free of shaking and shifting in the pressing process, it is ensured that positioning of the roller lining is accurate without error in the pressing process, and therefore the installation precision and position precision of the roller lining are ensured.

Owner:CSSC MARINE POWER

Method for producing MOS transistor with shallow-source electrode/drain electrode junction region

InactiveCN100423198CNo dislocationTransistorSemiconductor/solid-state device manufacturingCrystal structureDislocation

A method of fabricating a MOS transistor having shallow source / drain junction regions is provided. A diffusion source layer is formed on a semiconductor substrate on which gate patterns are formed. Same type or different type of impurities are implanted into the diffusion source layer several times in different directions. As a result, dislocation does not occur and the impurity concentration of the diffusion source layer can be nonuniformly controlled so that damage to the crystal structure of the semiconductor substrate does not occur. Also, the impurities nonuniformly contained in the diffusion source layer are diffused into the semiconductor substrate by a solid phase diffusion method to form shallow source / drain junction regions having LDD regions and highly doped source / drain regions by a self-alignment method.

Owner:ELECTRONICS & TELECOMM RES INST

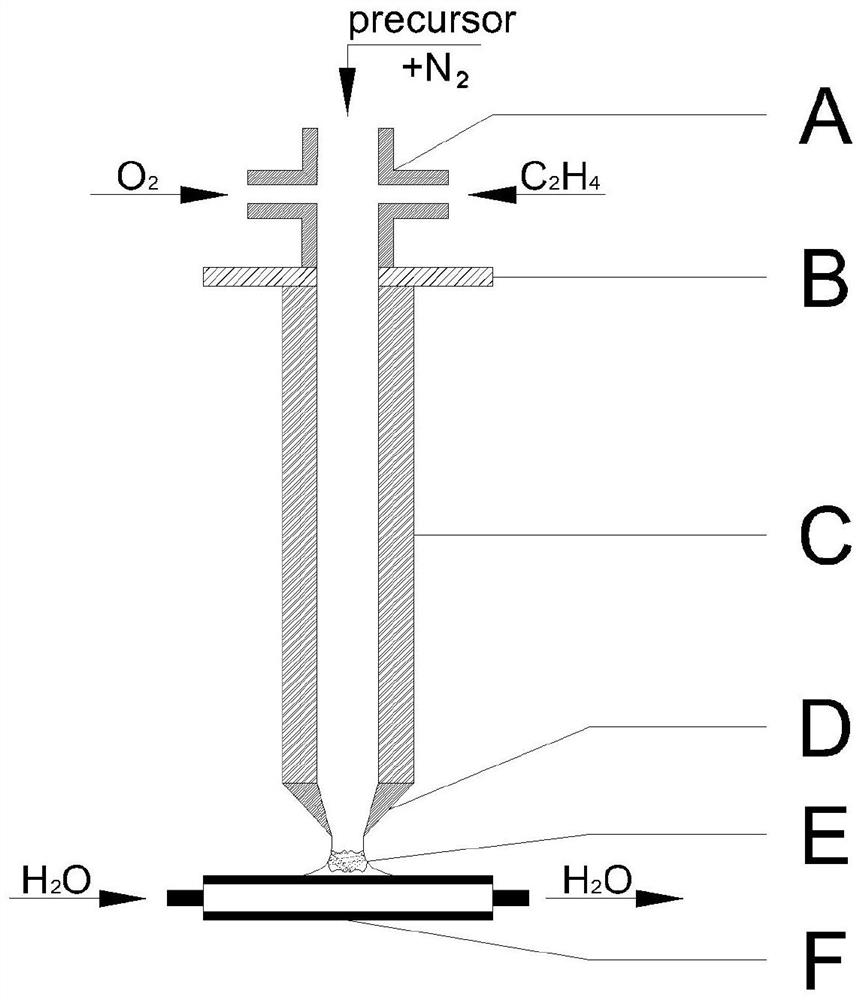

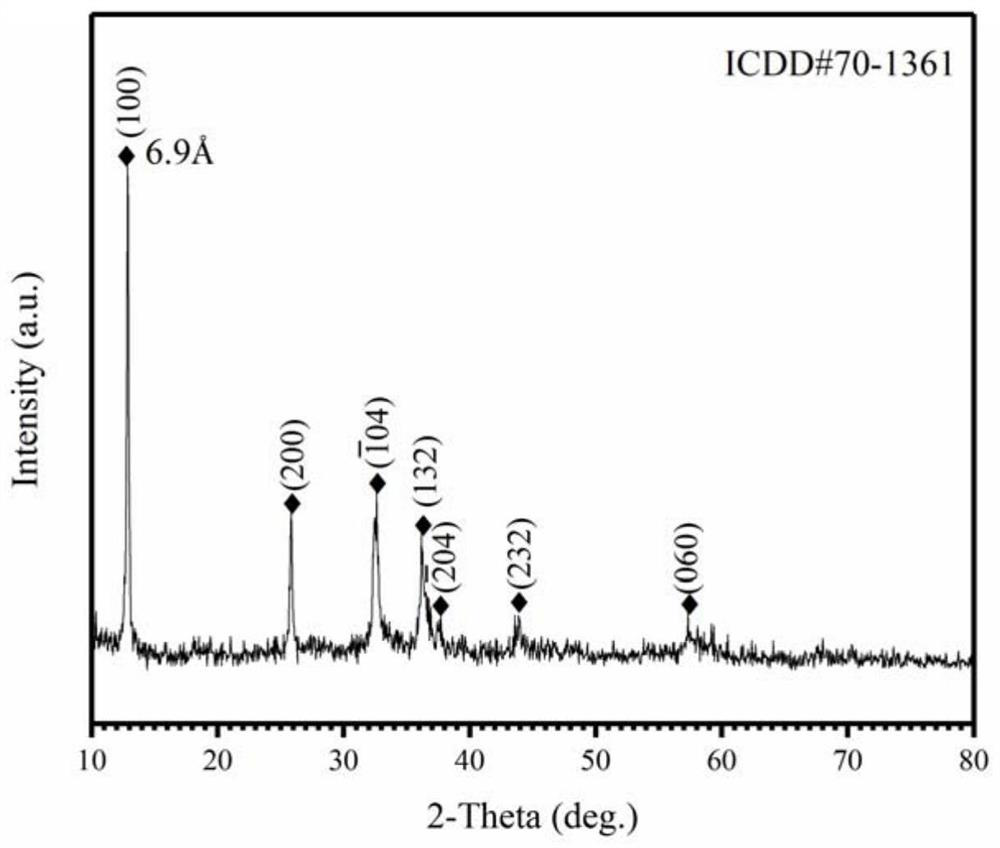

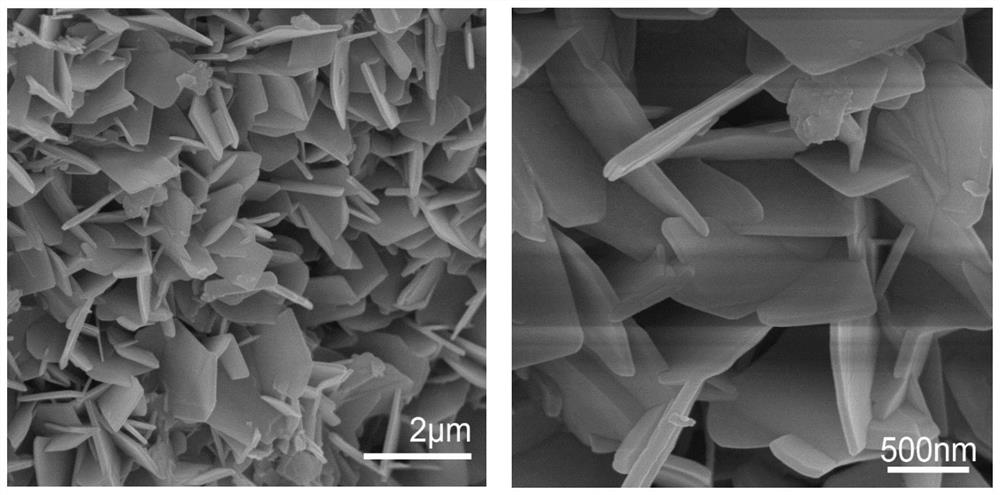

An ultrathin single crystal zn 3 (oh) 4 (no 3 ) 2 Structured hydroxyzinc nitrate nanosheets and preparation method thereof

ActiveCN110219052BGood single crystal morphologyEasy to shapeMaterial nanotechnologyPolycrystalline material growthChemical synthesisHydration reaction

The invention discloses an ultra-thin single crystal Zn 3 (OH) 4 (NO 3 ) 2 Hydroxyzinc nitrate nanosheets of structure and preparation method thereof, the preparation method of the hydroxyzinc nitrate nanosheets is as follows with hexahydrate zinc nitrate Zn(NO 3 ) 2 ·6H 2 O is the precursor, through the improved premixed flame synthesis method, the carrier gas is used to bring the precursor into the flame zone, and after passing through the temperature gradient of the flame zone, it is deposited on the surface of the water-cooled solid phase receiving plate to prepare the Zn 3 (OH) 4 (NO 3 ) 2 Structured 2D materials of hydroxyzinc nitrate nanosheets. The preparation method of hydroxyzinc nitrate nanosheets of the present invention overcomes unfavorable factors such as uneven product morphology, too many impurity phases, complicated experimental operations, and harsh conditions in complex chemical synthesis methods, and at the same time synthesizes ultra-thin nano-scale hydroxynitric acid for the first time Zinc-based substances to obtain Zn with excellent performance 3 (OH) 4 (NO 3 ) 2 Nanosheets.

Owner:NANJING UNIV OF SCI & TECH

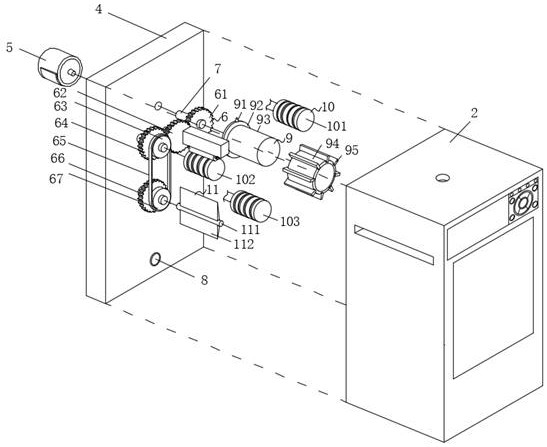

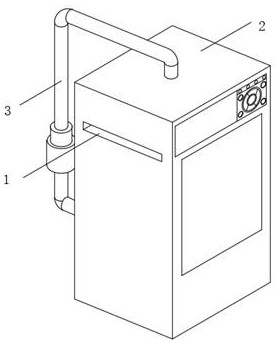

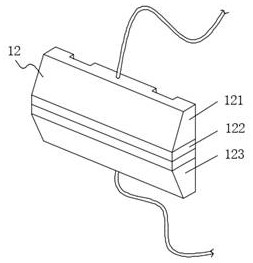

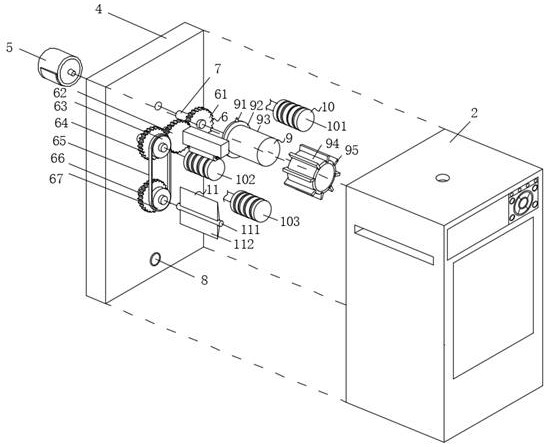

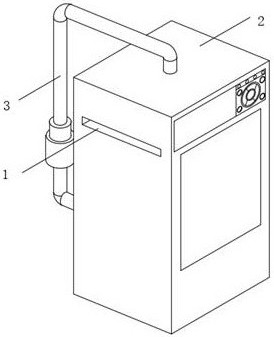

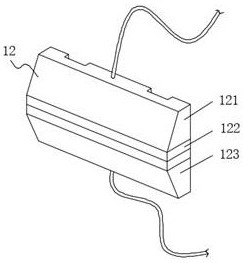

Cable inner core wire oiling device

ActiveCN113695125AReduce energy consumptionGuaranteed stabilityCleaning using toolsLiquid spraying apparatusDrive motorStructural engineering

The invention discloses a cable inner core wire oiling device, and belongs to the technical field of cable spraying oiling. The cable inner core wire oiling device comprises a machine shell, a rear shell is fixedly installed on the outer wall of one side of the machine shell, inner core grooves are formed in the outer walls of the two sides of the machine shell, and a driving motor is fixedly installed on the outer wall of one side of the rear shell; and a rotating shaft is fixedly mounted at one end of an output shaft of the driving motor, a mounting main shaft is fixedly mounted at one end of the rotating shaft, a transmission assembly is arranged outside the mounting main shaft and used for stabilizing a wire of a cable, and the transmission assembly is located in a shell cavity of the rear shell. According to the device, the transmission assembly and a wire guiding mechanism are arranged in the device, meanwhile, an oil spraying assembly is arranged in the device, through linkage design, cable conduction, preliminary oiling and oil stirring can be achieved through a same driving source, energy consumption is reduced, and meanwhile, the preliminary oiling effect can be guaranteed by widely spraying oil stirred in real time.

Owner:如东佳成再生资源科技有限公司

A cable inner core wire oil passing device

ActiveCN113695125BAchieve real-time mixingReduce consumptionCleaning using toolsLiquid spraying apparatusOil canElectric machinery

The invention discloses a cable inner core wire oil passing device, which belongs to the technical field of cable spray oil passing, and comprises a casing, a rear casing is fixedly installed on one side of the casing, and two sides of the casing are The outer walls are provided with inner core grooves, and a driving motor is fixedly installed on one side of the outer wall of the rear shell. There is a transmission assembly on the outside, which is used for the stable wire of the cable, and the transmission assembly is located in the shell cavity of the rear shell; in the present invention, the transmission assembly and the wire mechanism are arranged inside, and the oil sprinkling assembly is arranged inside, Through the linkage design, the conduction of the cable, the preliminary oiling and the stirring of the oil can all be realized through the same driving source, which reduces the energy consumption. At the same time, the real-time stirred oil is widely sprayed to ensure the preliminary oiling effect.

Owner:如东晟方硬质合金材料有限公司

Growth method of large size non-core YAG series laser crystal

ActiveCN101338453BIncrease concentrationNo corePolycrystalline material growthBy pulling from meltHigh concentrationOptoelectronics

The invention discloses a grower and a growing method of a laser crystal that belongs to YAS series with large size and no core, which belongs to the crystallization technology of the laser crystal. The invention comprises the grower adopting a Mo crucible pulling method heated by resistance and the crystal growing method comprising two procedures and four phases. The laser crystal of YAS series provided by the invention has large size of 35 to 50mm, high concentration (reaching 2.0at percent), no core, no dislocation and no scattering. In addition, the growing technology is stable; growing cycle is short; cost is low; and the yield of the crystal is high with above 85 percent.

Owner:成都东骏激光股份有限公司

Gallium nitride single crystal substrate manufacturing method based on magnetron sputtering aluminum nitride

InactiveCN113046712AAvoid damageNo dislocationPolycrystalline material growthVacuum evaporation coatingChemical physicsPhysical chemistry

The invention discloses a gallium nitride single crystal substrate manufacturing method based on magnetron sputtering aluminum nitride, which comprises magnesium aluminum scandium tetraoxide (ScAlMgO4), and is characterized by comprising the following steps: S1, selecting the magnesium aluminum scandium tetraoxide (ScAlMgO4) as a substrate; S2, forming an aluminum nitride (AlN) thin film layer on the magnesium aluminum scandium tetraoxide (ScAlMgO4) substrate by adopting a magnetron sputtering method; S3, epitaxially growing a gallium nitride (GaN) single crystal layer on the aluminum nitride (AlN) thin film layer formed in the step S2 through an HVPE vapor phase growth method in a high-temperature environment; and S4, removing the magnesium aluminum scandium tetraoxide (ScAlMgO4) substrate and the aluminum nitride (AlN) thin film layer on the gallium nitride (GaN) single crystal layer to obtain the gallium nitride (GaN) single crystal substrate. The magnetron sputtering method and the HVPE vapor phase growth method are used for secondary growth, the situation that the magnesium aluminum scandium tetraoxide substrate is damaged when the GaN crystal grows is effectively avoided, and manufacturing of the high-quality GaN crystal substrate free of dislocation and crystal defects is achieved.

Owner:WUXI WUYUE SEMICON CO LTD

High-insulativity LED tube lamp structure

InactiveCN104456217AFirmly connectedEasy to assemblePoint-like light sourceElectric circuit arrangementsElectricityHeat conducting

The invention discloses a high-insulativity LED tube lamp structure which comprises a lamp plate, a lamp plate frame and a power source. A rectifier IC in the power source is positioned at one end of the lamp plate, a constant-current circuit in the power source is positioned at the other end of the lamp plate, lamp beads are positioned between the rectifier IC and the constant-current circuit, the rectifier IC and the lamp beads are welded on the lamp plate and distributed along the length direction of the lamp plate frame, a non-welding face of the lamp plate and a plane of the lamp plate frame are in heat-conducting connection, an alternating-current first welding wire disc is arranged between an alternating-current input end of the rectifier IC and a first lamp holder close to the alternating-current input end, the alternating-current first welding wire disc is electrically connected with a wiring end of the first lamp holder, another alternating-current input end of the rectifier IC routes onto an alternating-current second welding wire disc, close to a second lamp holder, at the other end of the lamp plate, the alternating-current second welding wire disc is electrically connected with a wiring end of the second lamp holder, a positive output end of the rectifier IC is electrically connected with one end of the lamp plate LED lamp bead, the other end of each lamp plate LED lamp bead is electrically connected with a positive input end of the constant-current circuit, and a negative output end of the constant-current circuit is electrically connected with a negative output end of the rectifier IC. The high-insulativity LED tube lamp structure is high in structuredness and reliability.

Owner:XIAN XINWEI INFORMATION TECH

A mold that facilitates the disassembly and assembly of exhaust inserts

The invention relates to the technical field of molds, in particular to a mold with an exhaust insert convenient to disassemble and assemble. The mold comprises a mold core, the exhaust insert, an insert base and a first mold plate. The exhaust insert is arranged on the insert base, the insert base is arranged on the mold core, and the mold core is arranged on the first mold plate. The mold further comprises an ejection rod, an ejection rod base and a cam. The first mold plate is provided with a guide hole for the ejection rod to move in the axial direction. One end of the ejection rod is connected with the insert base, and the other end of the ejection rod is connected with the ejection rod base. The cam is connected to the insert base in an abutting mode and presses the ejection rod to move in the axial direction under the drive effect of external force. Compared with the prior art, there is no need to disassemble the mold core and the mold plate when the exhaust insert needs to be cleaned, the exhaust insert can be disassembled through the compact matching structure of the cam and the ejection rod, the reliability is high, energy consumption is small, and the work is stable.

Owner:东莞华誉精密技术有限公司

LED (light emitting diode) tubular lamp structure with high technological performance

InactiveCN104456216AFirmly connectedEasy to assemblePoint-like light sourceElectric circuit arrangementsElectricityEngineering

Owner:XIAN XINWEI INFORMATION TECH

Manufacturing method of gallium nitride single crystal substrate based on plasma CVD

PendingCN113161226AAvoid damageNo dislocationPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalSilicon oxide

The invention discloses a manufacturing method of a gallium nitride single crystal substrate based on plasma CVD (chemical vapor deposition). The substrate comprises scandium aluminum magnesium tetraoxide (ScAlMgO4). The method comprises the following steps of: S1, selecting the scandium aluminum magnesium tetraoxide (ScAlMgO4) as a substrate base; S2, forming a silicon dioxide (SiO2) film layer on the scandium aluminum magnesium tetraoxide (ScAlMgO4) substrate base by adopting either a plasma CVD (Chemical Vapor Deposition) method or a thermal CVD method; S3, epitaxially growing a gallium nitride (GaN) single crystal layer on the silicon dioxide (SiO2) film layer formed in the step S2 through an HVPE method at a high temperature; and S4, removing the scandium aluminum magnesium tetraoxide (ScAlMgO4) substrate base and the silicon dioxide (SiO2) film layer on the gallium nitride (GaN) single crystal layer. According to the method, secondary growth is carried out by using a plasma CVD or thermal CVD method and an HVPE method, so that the damage to the scandium aluminum magnesium tetraoxide substrate during the growth of the GaN crystal is effectively avoided, and the manufacturing of the high-quality GaN crystal substrate without dislocation and crystal defects is realized.

Owner:WUXI WUYUE SEMICON CO LTD

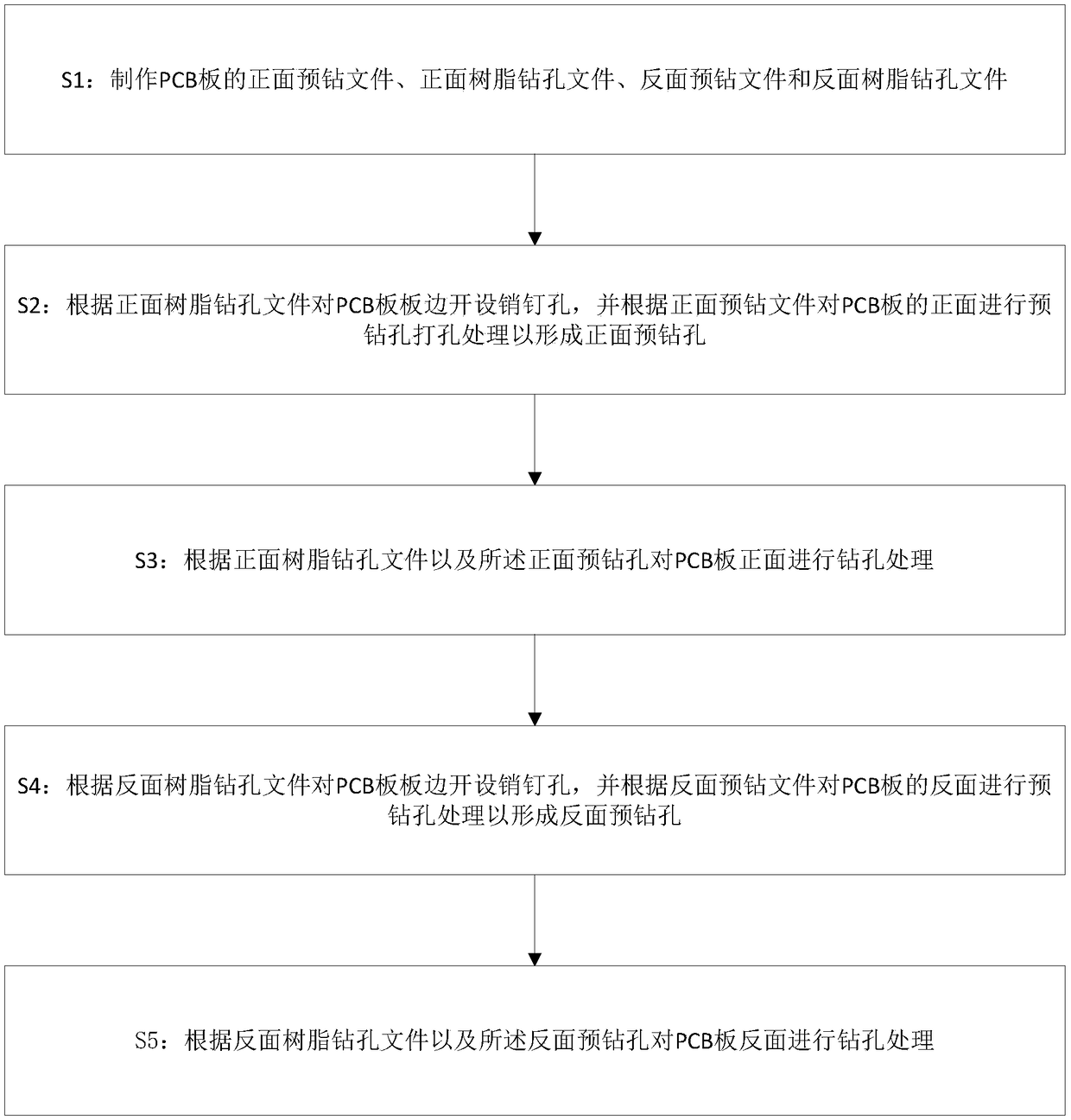

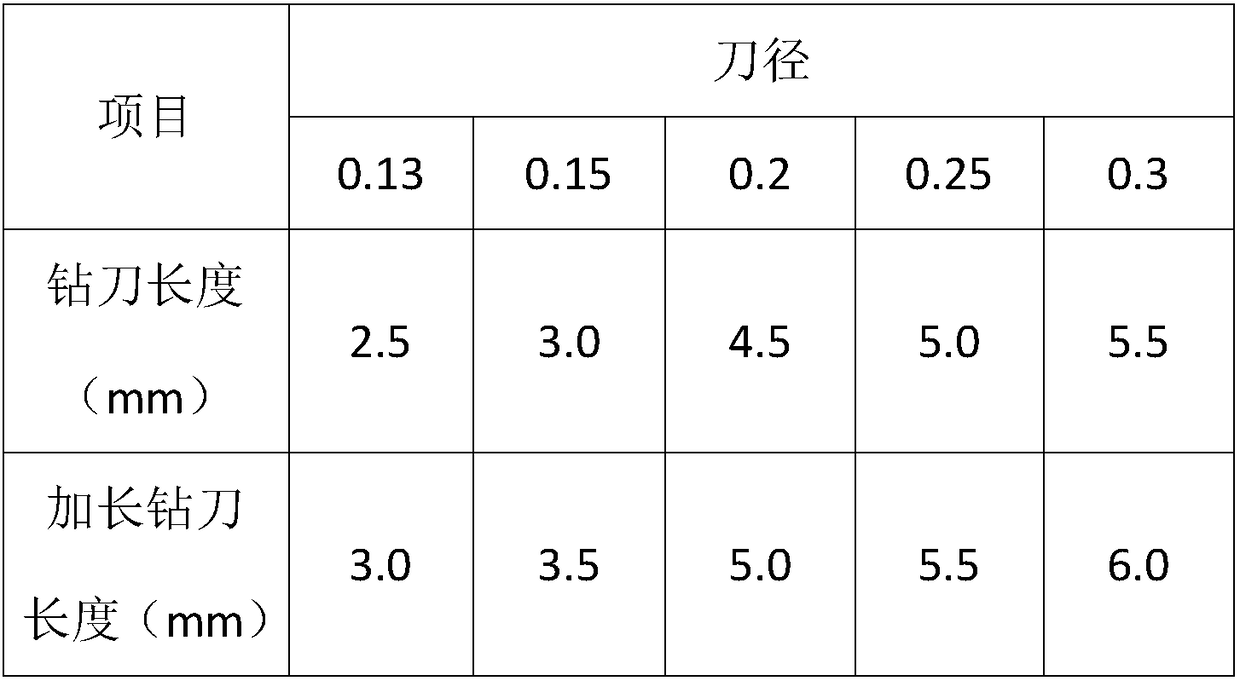

Drilling method for improving drilling accuracy of high-thickness-diameter PCB

InactiveCN109176703AImprove drilling accuracyImprove production quality and yieldMetal working apparatusCutting forceHole drilling method

The invention discloses a drilling method for improving the drilling accuracy of a high-thickness-diameter PCB. The method comprises the following steps that a front side pre-drilling file, a front side resin drilling file, a reverse side pre-drilling file and a reverse side resin drilling file of the PCB are prepared; a pin hole is formed in the PCB edge according to the front resin drilling file, and the front side of the PCB is subjected to pre-drilling slotting process to form a front side pre-drilling hole according to the front pre-drilling file; the front side of PCB is subjected to drilling process according to the front side resin hole drilling file and the front side pre-drilling hole; a pin hole is formed in the PCB edge according to the reverse side resin drilling file, and thereverse side of the PCB is subjected to pre-drilling process to form a reverse side pre-drilling hole according to the reverse side pre-drilling file; and the reverse side of the PCB is subjected tothe drilling process according to the reverse side resin drilling file and the reverse side pre-drilling hole. A pre-drilling process is introduced, cutting force resistance produced in the resin drilling process is greatly reduced, and the yield of production quality is improved.

Owner:GUANGZHOU MEADVILLE ELECTRONICS

High-power LED lamp structure with good manufacturability

InactiveCN104534311AFirmly connectedEasy to assemblePoint-like light sourceElectric circuit arrangementsElectricityEngineering

The invention discloses a high-power LED lamp structure with good manufacturability. The high-power LED lamp structure with good manufacturability comprises a lamp panel, a lamp panel frame and a power source, wherein a rectification IC in the power source is arranged at one end of the lamp panel, a constant current circuit in the power source is arranged at the other end of the lamp panel, and lamp beads are arranged between the rectification IC and the constant current circuit; the rectification IC and the lamp beads are welded on the lamp panel, and are distributed in the length direction of the lamp panel frame; the non-welding surface of the lamp panel and the plane surface of the lamp panel frame are in heat conduction connection; a first alternating-current welding wire coil is arranged at one alternating-current input end of the rectification IC and an adjacent first lamp holder, and is electrically connected with the wiring end of the first lamp holder; a wire penetrates through the lamp panel, and extends from the other alternating-current input end of the rectification IC to a second alternating-current welding wire coil arranged on the portion, close to a second lamp holder, of the other end of the lamp panel, and the second alternating-current welding wire coil is electrically connected with the wiring end of the second lamp holder; the positive output end of the rectification IC is electrically connected with one end of each LED lamp bead of the lamp panel, the other end of each LED lamp bead of the lamp panel is electrically connected with the positive input end of the constant current circuit, and the negative output end of the constant current circuit is electrically connected with the negative output end of the rectification IC. The high-power LED lamp structure is good in structural performance and high in reliability.

Owner:XIAN XINWEI INFORMATION TECH

A guide device for in-line hip replacement

The invention discloses a direct insertion type guide device for hip replacement. The direct insertion type guide device comprises a handle, a guide connecting rod, an acetabular cup connector and a sleeve, wherein the lower end of the handle is connected to the acetabular cup connector; one end of the guide connecting rod is connected to one side, close to the upper end, of the handle, and the other end of the guide connecting rod is provided with a sleeve hole into which the sleeve is inserted; the acetabular cup connector comprises an installing shaft, the center shaft of the sleeve is approximately overlapped with the axis of the installing shaft, and the handle and the guide connecting rod are fixedly connected through a first insertion rod and a first socket matched with each other; the lower ends of the acetabular cup connector and the handle are fixedly connected through a second insertion rod and a second socket matched with each other. The guide device is easy to assemble and disassemble, and can be used for accurately locating, inserting and press-matching an acetabular prosthesis without dislocation.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com