Roller lining installation positioning device and method

A roller bushing, installation and positioning technology, applied to workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problem that the installation accuracy and position accuracy of the roller bushing cannot be guaranteed, the installation tool structure is complicated, and the cost is long Time and manpower and other issues, to achieve the effect of low cost, convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

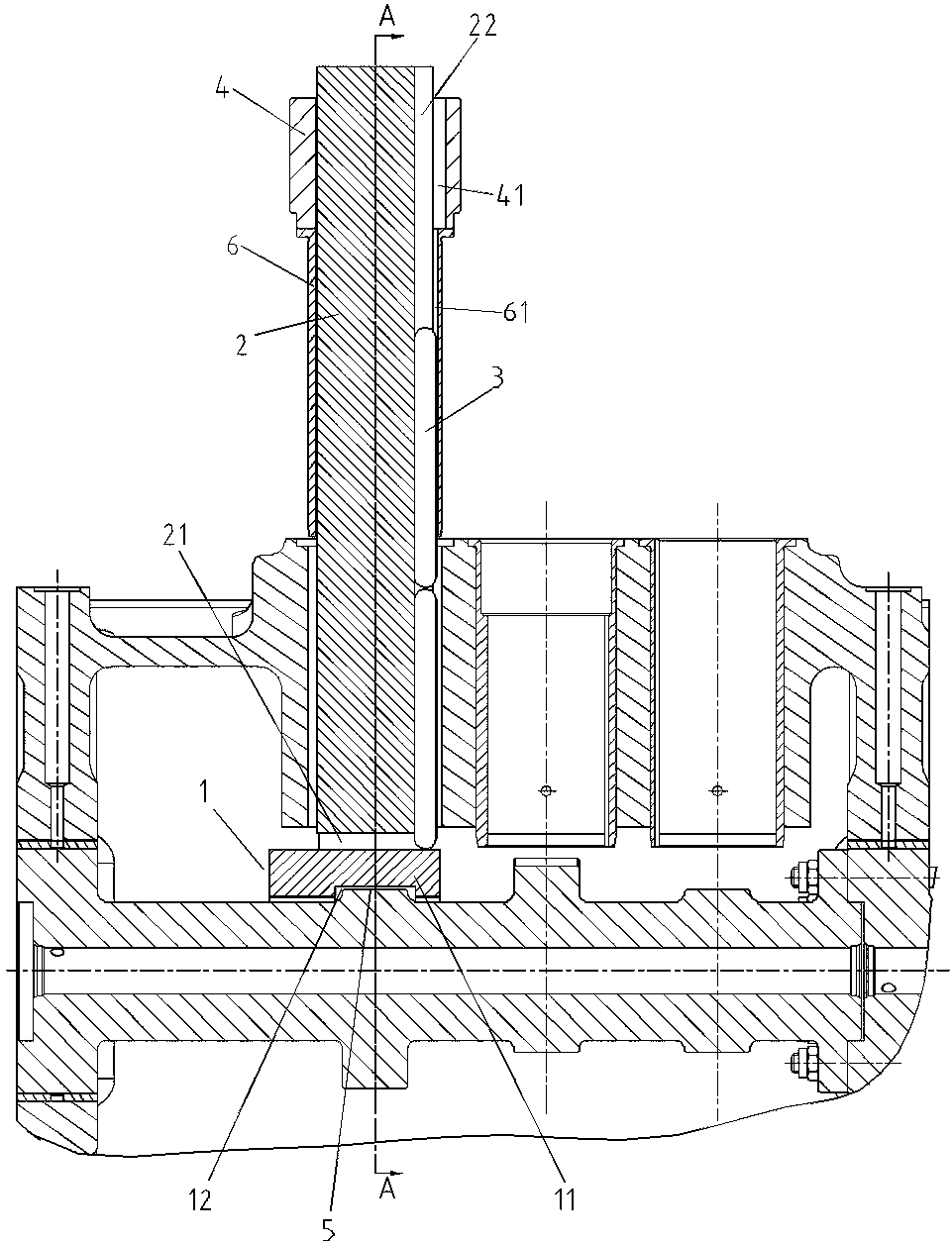

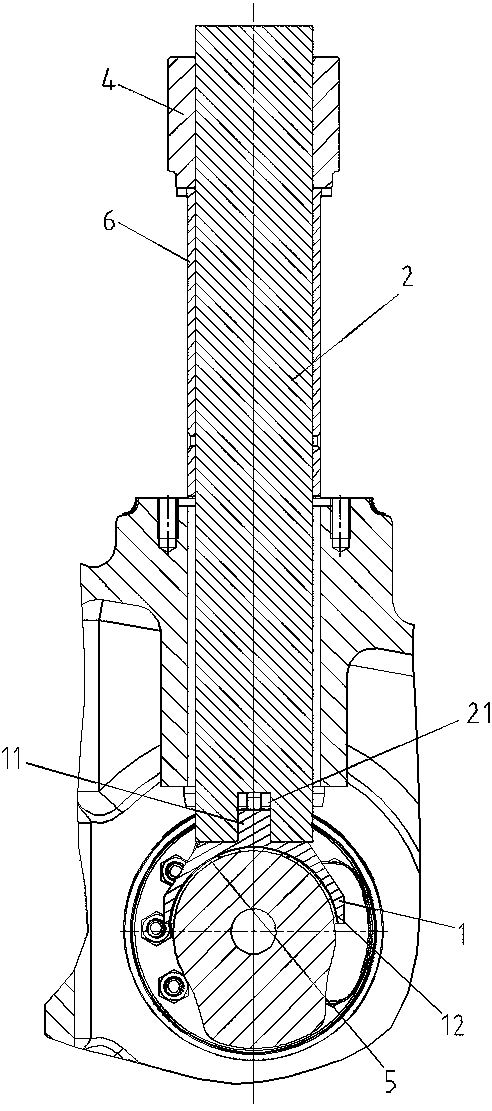

[0023] like figure 1 and figure 2 As shown, the present invention includes a support 1 , a positioning shaft 2 , two guide keys 3 and a pressing block 4 . The support 1 is an arc-shaped structure, the middle part of which extends upwards a positioning boss 11, and the bottom of the support 1 is provided with an arc-shaped positioning groove 12. The support 1 is supported on the cam base circle 5 corresponding to the camshaft of the diesel engine, and the camshaft of the diesel engine corresponds to the cam base circle 5. The base circle 5 is inserted into the arc-shaped positioning groove 12 at the bottom of the support 1 . The lower end of the positioning shaft 2 vertically passes through the installation hole of the diesel engine roller and is supported on the upper side of the support 1. The bottom of the positioning shaft 2 is provided with a positioning groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com