Method for manufacturing gallium nitride single crystal wafer

A gallium nitride monolithic and manufacturing method technology, which is applied in the field of manufacturing, can solve problems such as crystal defects, fractures, wafer deformation and warping, and achieve the effect of no crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

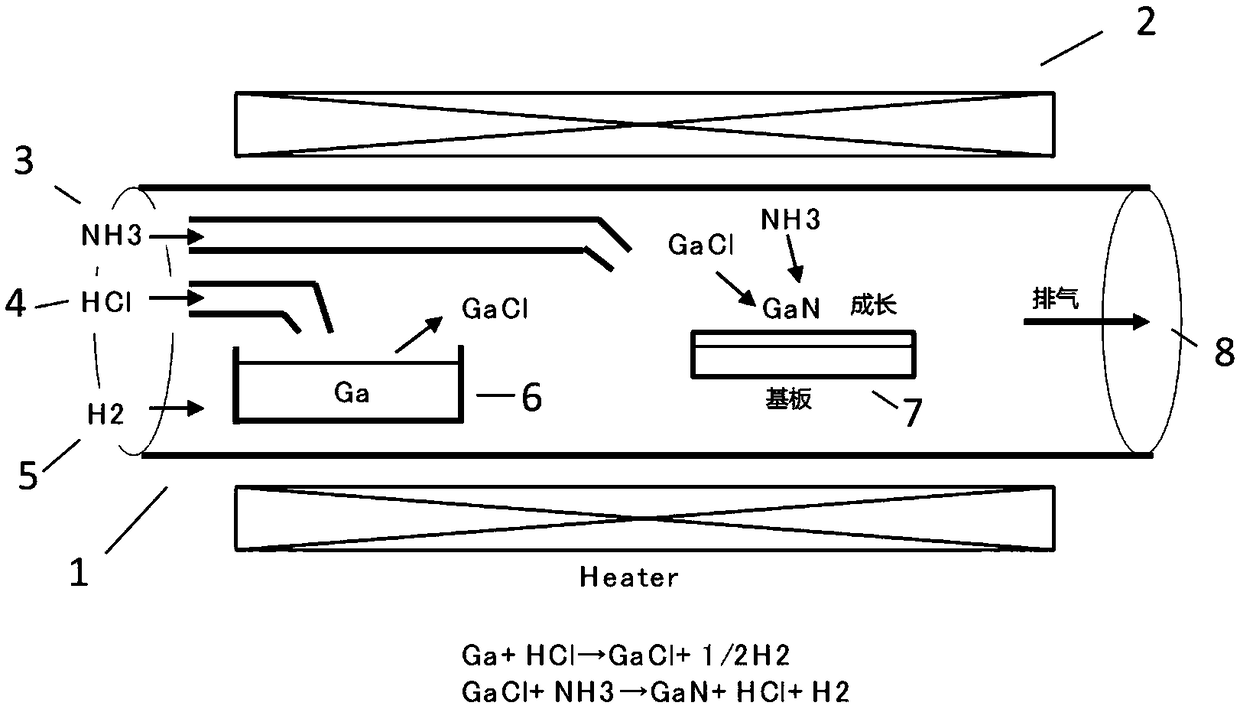

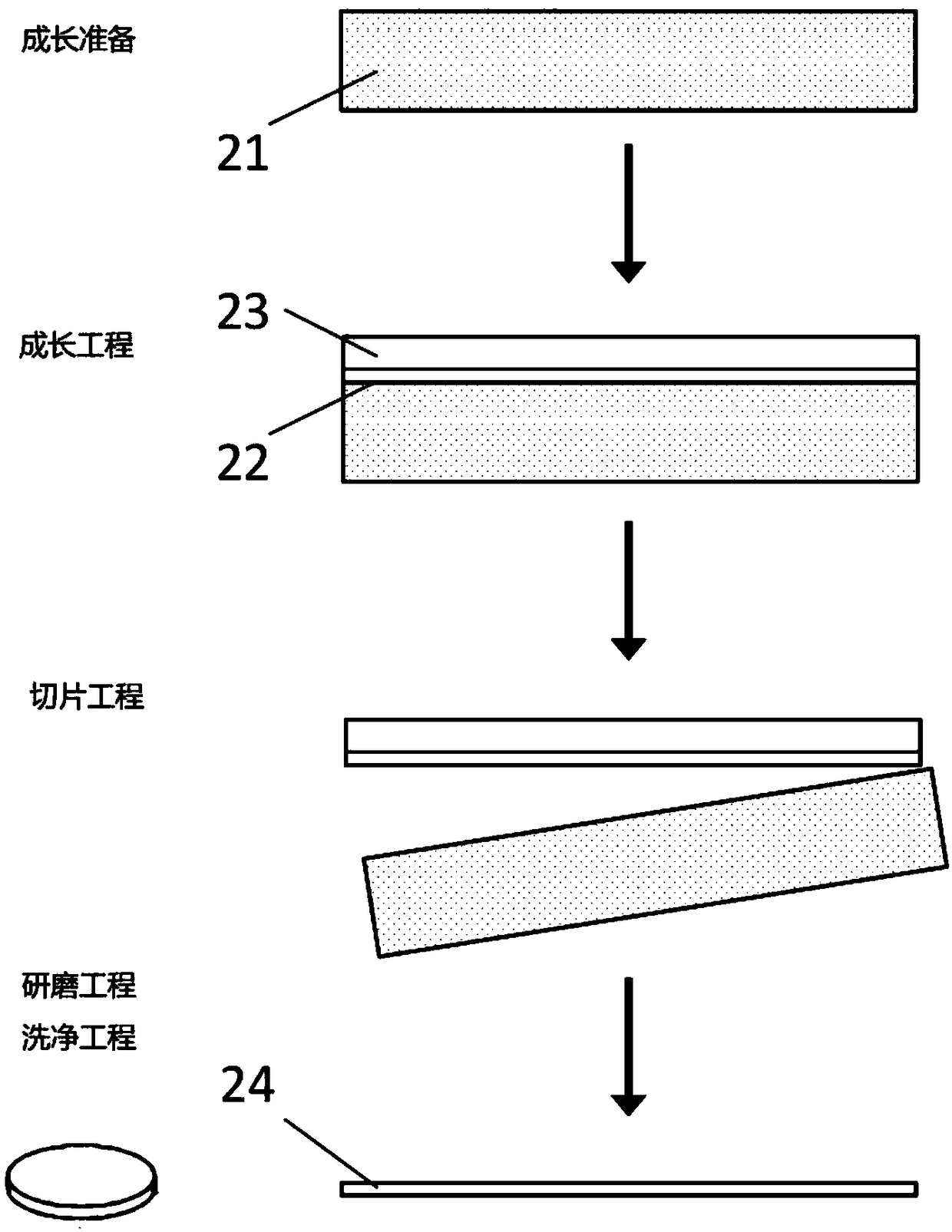

[0024] Example 1 (HVPE method combined with two-stage growth method to produce a single GaN wafer)

[0025] figure 2 The schematic diagram of the manufacturing process of Example 1 implemented based on the method of the present invention (manufacturing of a single GaN wafer) and its process flow (preparation stage for crystal growth—crystal growth process—crystal slicing process—grinding and cleaning process) are shown. After completing various preparations before crystal growth (detailed steps are painstakingly omitted here), the GaN buffer layer 22 and the GaN epitaxial layer 23 are grown on the SCAM substrate 21 by using the HVPE method combined with the two-stage growth method. The GaN layer is stripped from the SCAM substrate, and the stripped GaN layer is ground and cleaned to obtain a finished GaN single crystal substrate 24.

[0026] (1) Crystal growth process of GaN buffer layer

[0027] A 2 inch diameter SCAM substrate was placed on a pedestal (not shown in the fi...

example 2

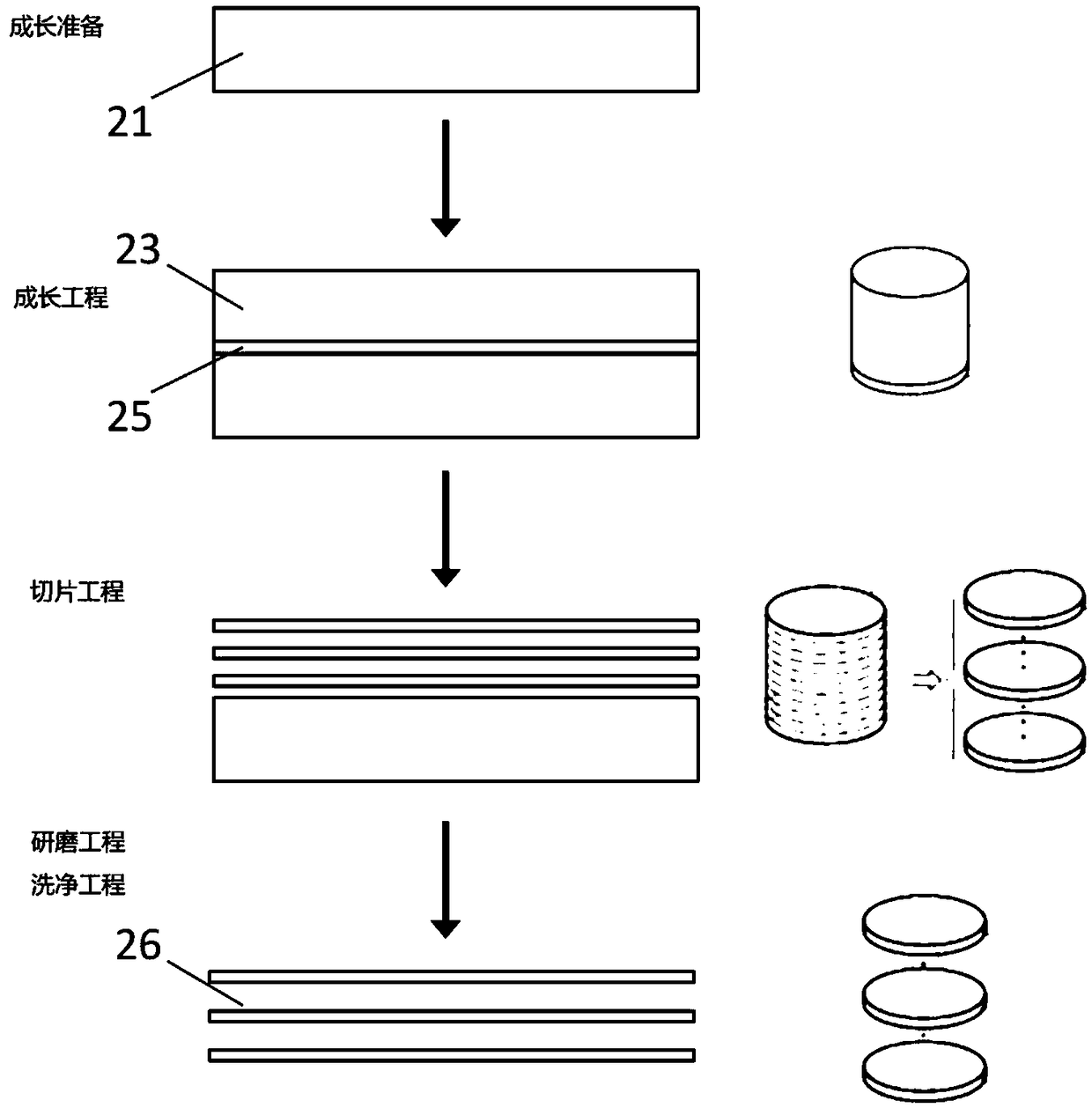

[0034] Example 2 (HVPE method combined with two-stage growth method to produce GaN crystal ingot and multiple wafers)

[0035] image 3 A schematic diagram of the manufacturing process implemented based on the method of the present invention (fabrication of GaN crystal ingots and multiple wafers) is shown. After completing a series of preparatory work in advance (the detailed steps are omitted here), the HVPE method combined with the two-stage growth method was used to complete the In growth process on the SCAM substrate 21. x Ga 1-x Fabrication of N (x=0.17) layer 25 and GaN epitaxial layer 23 . The GaN crystal ingot is peeled off from the SCAM substrate, and several GaN wafers 26 are obtained after a slicing process, a grinding process, and a cleaning process.

[0036] (1)In x Ga 1-x Crystal growth process of N(x=0.17) layer

[0037] A SCAM substrate 7 with a diameter of 2 inches was placed on a susceptor (not shown in the figure) in the reaction furnace 1 (HVPE appara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com