Nitrogen doping agent feeding device and method and manufacturing system of nitrogen-doped single crystal silicon rod

A feeding device and feeding method technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as dislocation of single crystal silicon rods, increased volatilization, and scrapping of single crystal silicon rod products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

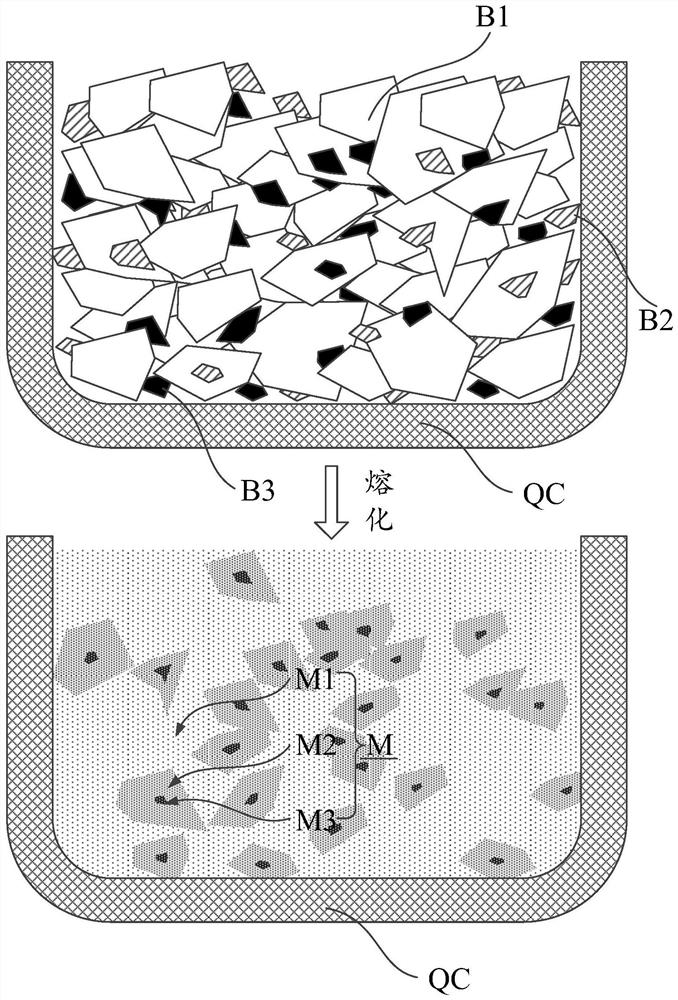

[0028] see figure 1 , which shows an implementation of nitrogen doping in conventional technical solutions. Such as figure 1 As shown, polysilicon raw material B1 and other dopants such as boron B2 are housed in a quartz crucible QC together with silicon nitride B3, wherein polysilicon raw material B1 is schematically shown by the area surrounded by a wire frame, and boron dopant B2 The silicon nitride B3 is schematically indicated by a black-filled area, schematically indicated by a region filled with oblique lines. After the quartz crucible QC is heated to melt the polysilicon raw material B1, boron dopant B2 and silicon nitride B3 contained in the quartz crucible QC, a melt M including silicon atoms, boron atoms and nitrogen atoms can be obtained. However, in the above i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com