Growth method of large size non-core YAG series laser crystal

A laser crystal and growth method technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult to obtain, low crystal utilization rate, high cost, etc., and achieve coreless, low cost, and short growth cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

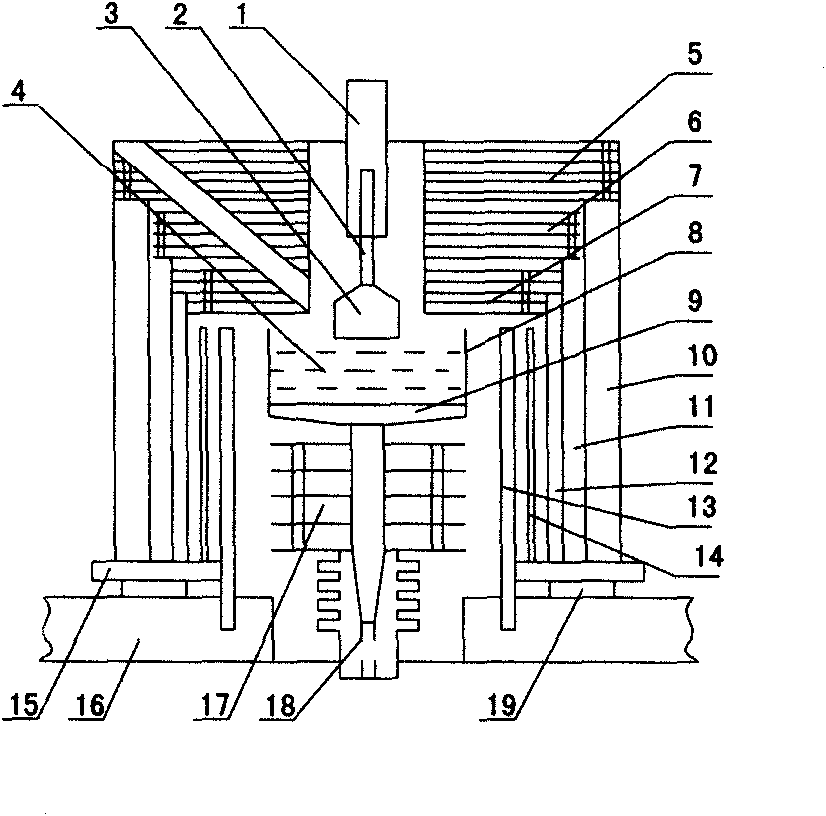

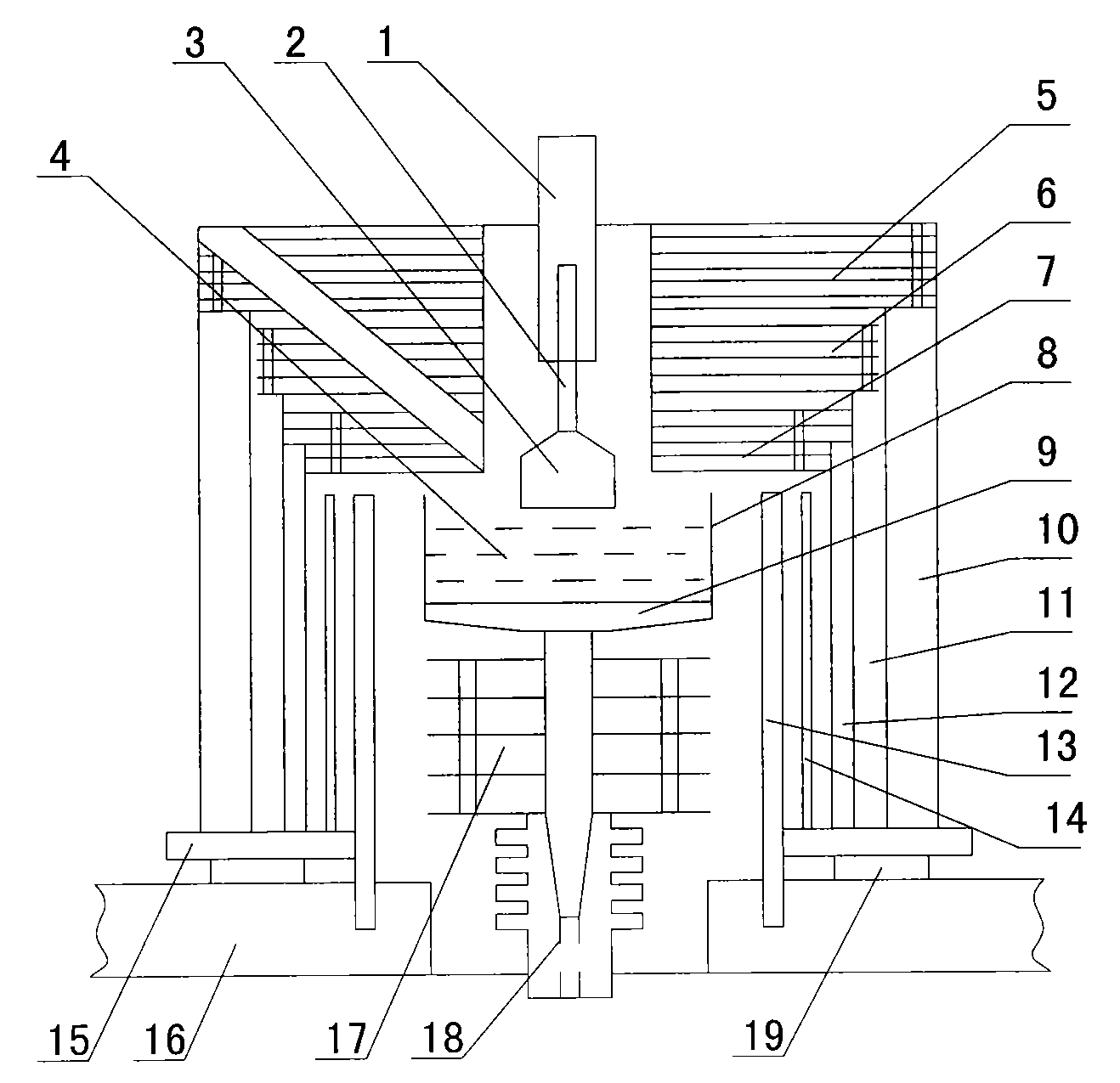

[0026] Such as figure 1 As shown, a large-size coreless YAG series laser crystal growth device includes a tray 15 connected to the electrode plate 16 through an alumina gasket 19, and molybdenum side insulation screens 10, 11, 12 placed on the tray 15, molybdenum Molybdenum upper insulation screens 5, 6, and 7 are arranged on the upper ends of the side insulation screens 10, 11, and 12, and a resistance heater 13 is installed on the inner side of the molybdenum side insulation screen 12, and the resistance heater 13 is directly connected with the electrode plate 16, and the molybdenum crucible holder 9 passes through The graphite joint 18 is connected with the lower transmission system of the single crystal furnace, a molybdenum table cover 17 is arranged between the graphite joint 18 and the molybdenum crucible holder 9, and the molybdenum crucible 8 is provided on the molybdenum crucible holder 9, and the molybdenum crucible 8 is equipped with a melt 4, The diameter of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com