Air-cooled fuel cell stack and metal bipolar plate thereof

A metal bipolar plate, fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as unreasonable distribution of water and heat in fuel cells, flooded membrane electrodes, and unfavorable mass production. , to solve the effect of reducing the performance of the stack, improving the distribution of water and heat, and increasing the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

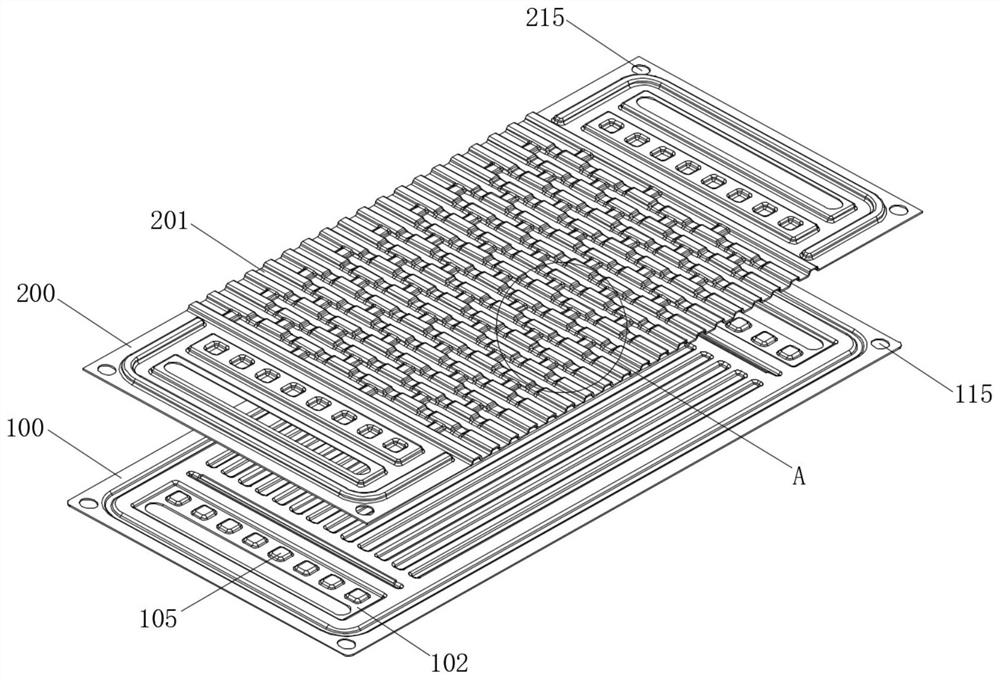

[0050] See Figure 1 to Figure 6 , the air-cooled fuel cell stack of this embodiment includes an air-cooled fuel cell metal bipolar plate, and the air-cooled fuel cell metal bipolar plate includes stacked and fixedly connected anode plates 100 made by a stamping process and Cathode plate 200 .

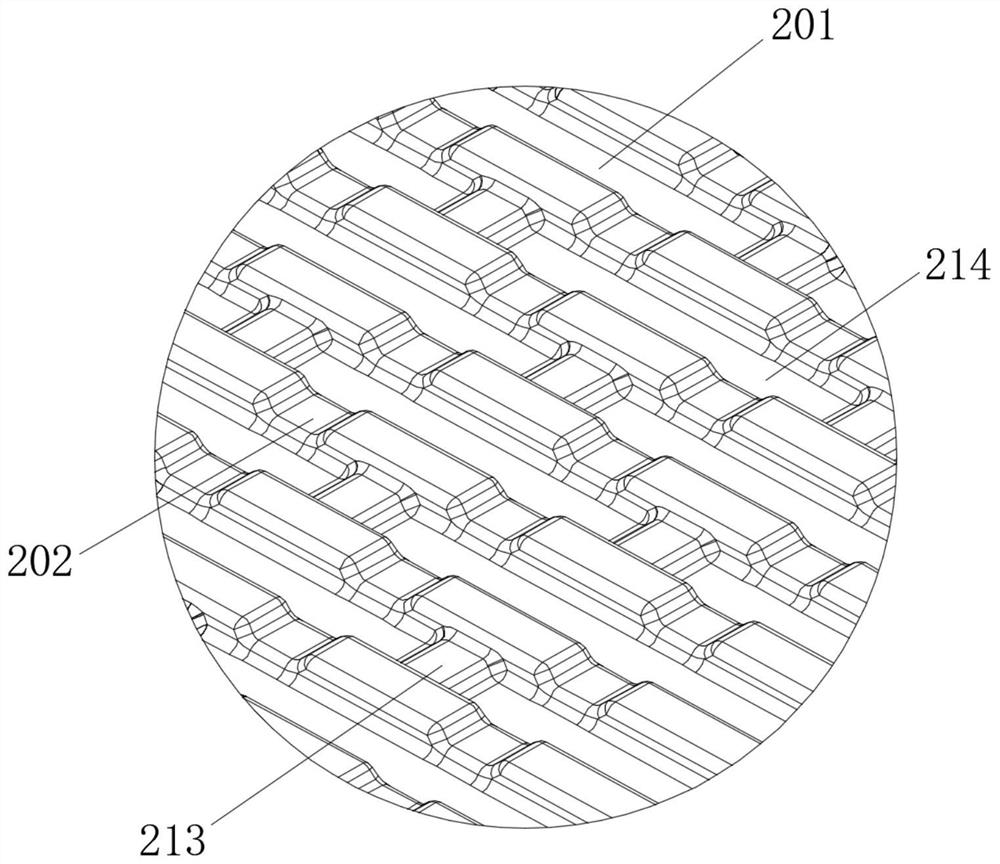

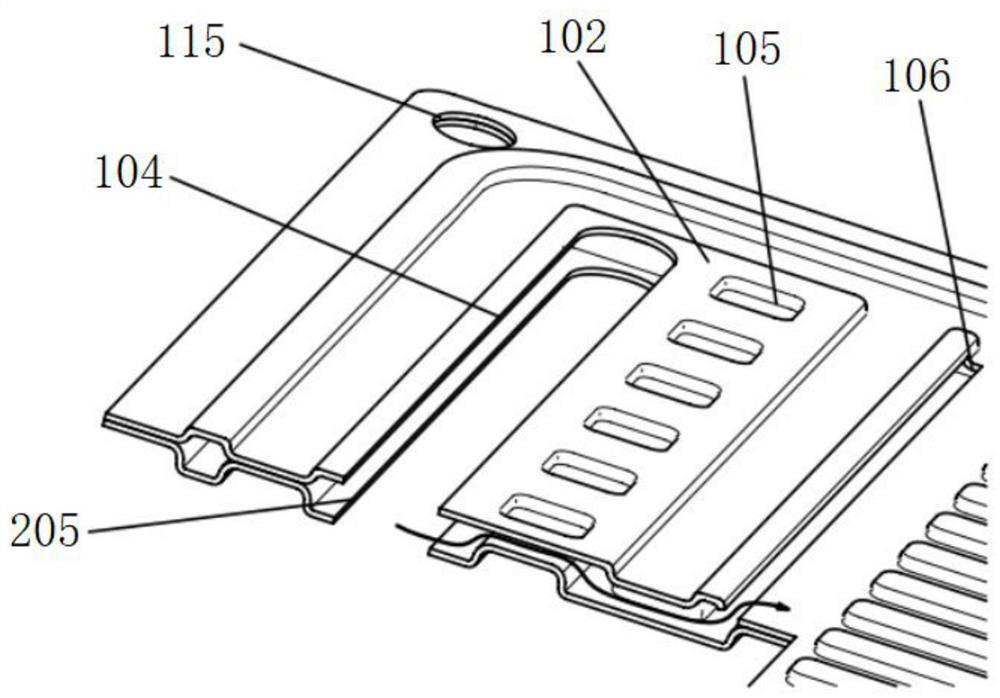

[0051] The anode plate 100 and the cathode plate 200 are made of metal materials with gas barrier properties and electron conductivity, such as aluminum alloy, aluminum plate, copper, stainless steel, titanium or titanium alloy. The surface of the anode plate 100 opposite to the cathode plate 200 is the reaction gas flow surface, and the surface of the anode plate 100 and the cathode plate 200 opposite is the cooling surface. A plurality of first fuel gas flow channels 101 extending along the length direction of the anode plate 100 are provided in parallel on the reaction gas flow surface of the anode plate 100 . The fuel gas first flow channels 101 are formed between the ridges form...

Embodiment 2

[0064] This embodiment is basically the same as Embodiment 1, except that the anode plate 100 and the cathode plate 200 are laminated and fixedly connected by means of glue injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com