Large-size single crystal segment-taking ending structure and control method thereof

A control method and large-scale technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of low production efficiency in finishing control, and achieve the effect of universal controllability and high universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

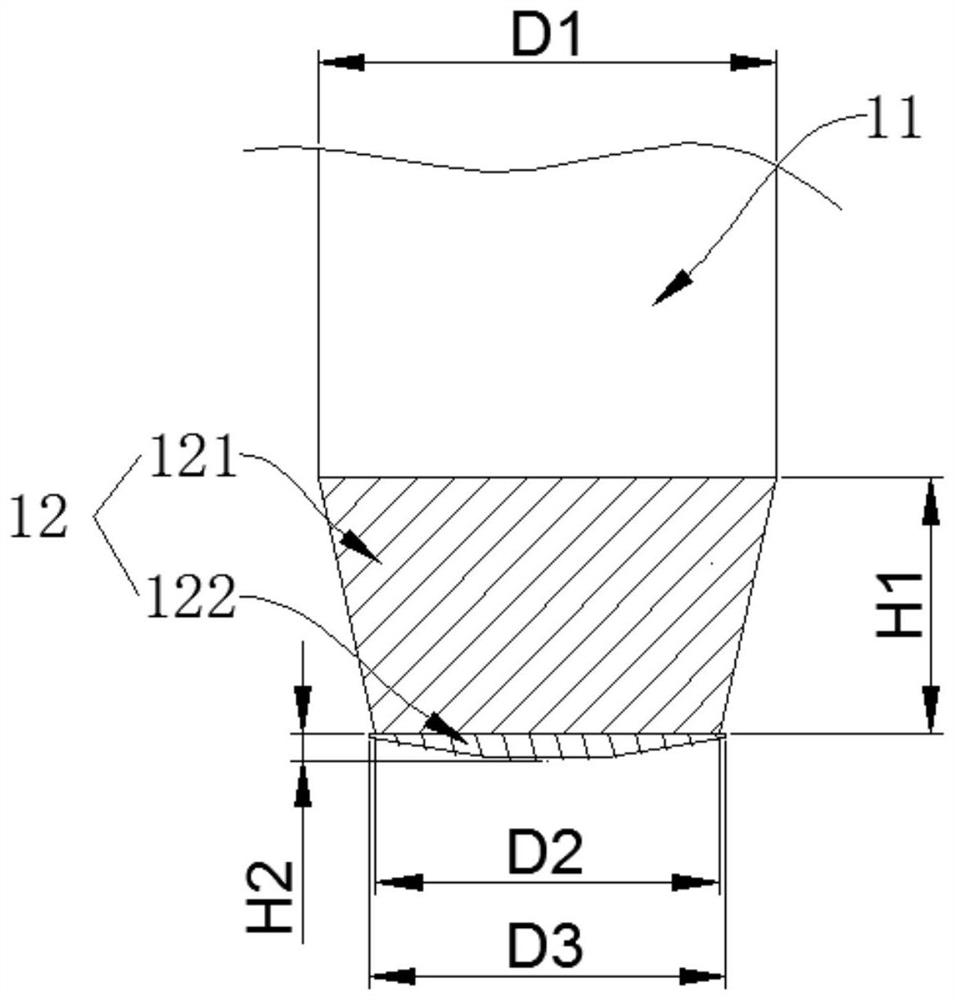

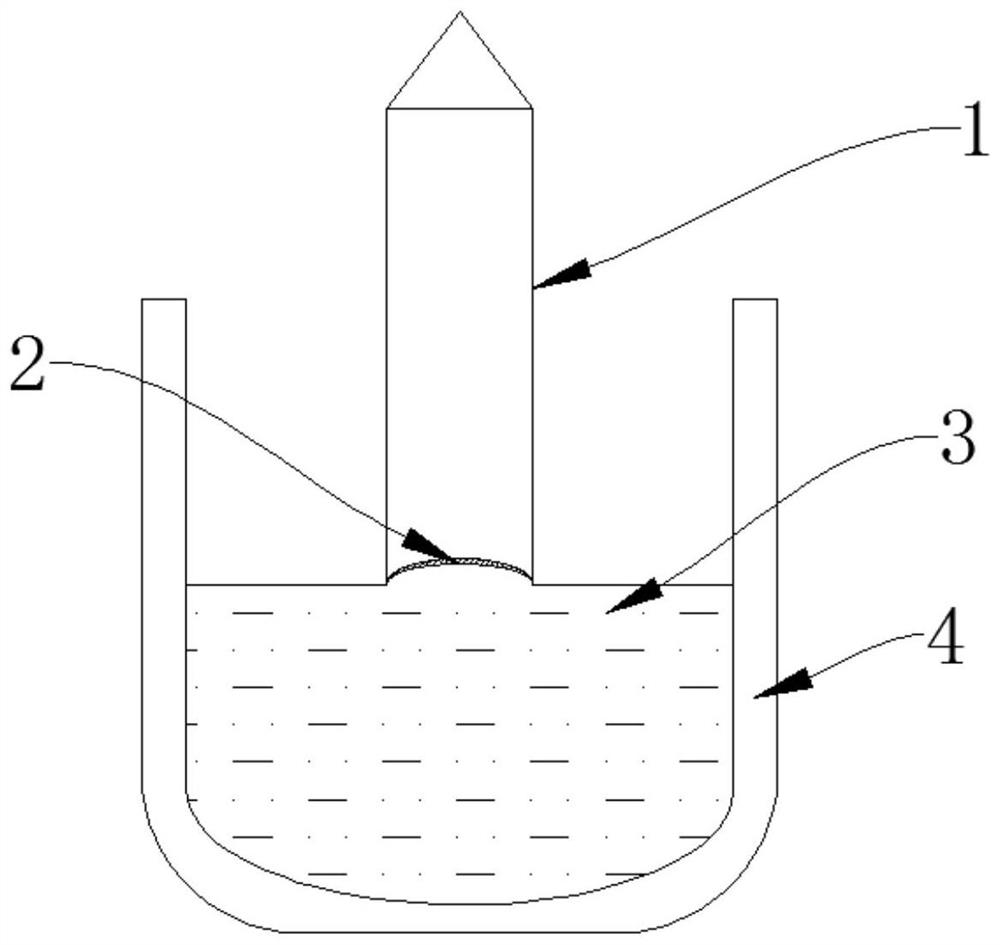

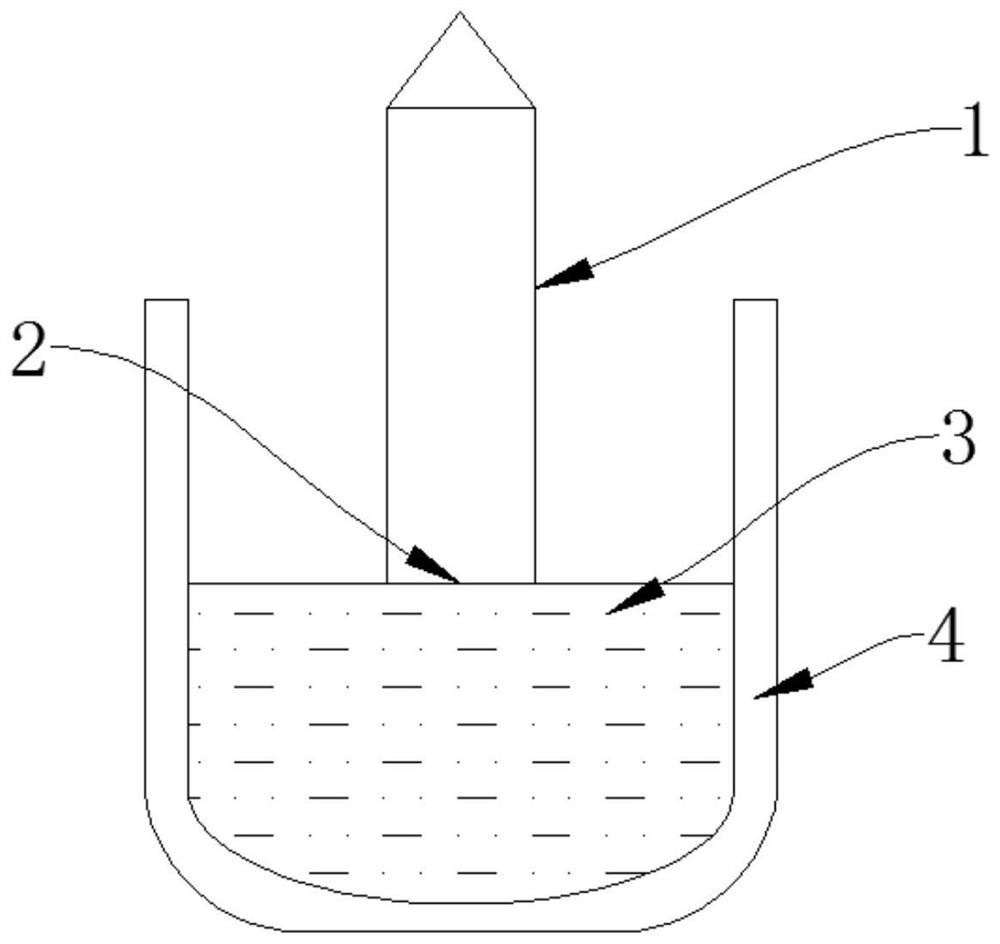

[0040] The single crystal diameter is 240m, and the Czochralski single crystal furnace is Jingsheng 105s.

[0041] S1: When the equal-diameter section 11 is completed, the power of the main heater is 65kW, the crystal pulling speed is 97mm / hr, the rotation speed of the crystal 1 is 10r / min, and the rotation speed of the crucible 4 is 10r / min.

[0042] At the beginning of finishing, keep the crystal rotation and crucible rotation unchanged, manually click the start finishing button, and keep the diameter control module running continuously and stop the crucible 4 from rising. 70kW after a 5kW increase and stay at 70kW until the end of the tail. At the same time, manually set the initial pulling speed of the crystal 1 in the upper section 121 to 60mm / hr and slowly increase it. After the finishing lasts for 30 minutes, the pulling speed of the crystal 1 rises to 61mm / hr, and the upper section 121 is finished. At this time, the ending shape of the crystal 1 is a truncated conical...

Embodiment 2

[0047] The single crystal diameter is 280m, and the Czochralski single crystal furnace is Jingsheng 105s.

[0048] S1: When the equal-diameter section 11 is completed, the power of the main heater is 63.8kW, the crystal pulling speed is 95mm / hr, the rotation speed of the crystal 1 is 10r / min, and the rotation speed of the crucible 4 is 10r / min.

[0049] When starting to finish, keep the crystal rotation and crucible rotation unchanged, manually click the start finishing button, and keep the diameter control module running continuously and stop the crucible 4 from rising. At this time, on the basis of the main heater power 63.8kW at the end of the equal diameter A quick 7.2kW boost to 71kW and a constant 71kW until the finish. At the same time, manually set the initial pulling speed of the crystal 1 in the upper section 121 to 63mm / hr and slowly increase it, and after finishing for 35 minutes, the pulling speed of the crystal 1 rises to 64mm / hr, and the upper section 121 is fin...

Embodiment 3

[0054] The single crystal diameter is 310m, and the Czochralski single crystal furnace is Jingsheng 105s.

[0055] S1: When the equal-diameter section 11 is completed, the power of the main heater is 61kW, the crystal pulling speed is 90mm / hr, the rotation speed of the crystal 1 is 10r / min, and the rotation speed of the crucible 4 is 10r / min.

[0056]When starting to finish, keep the crystal rotation and the crucible rotation unchanged, manually click the start finishing button, and keep the diameter control module running continuously and stop the crucible 4 from rising. At this time, based on the main heater power 61kW at the end of the isometric A 12kW boost to 73kW and a constant 73kW until the tail end. At the same time, manually set the initial pulling speed of the crystal 1 in the upper section 121 to 65mm / hr and slowly increase it, and after finishing for 45 minutes, the pulling speed of the crystal 1 rises to 69mm / hr, and the upper section 121 is finished. At this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com