Preparation method of nano-porous Ru-Fe-Co alloy with high ammonia borane hydrolysis hydrogen production catalytic activity

A ru-fe-co, nanoporous technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of complex preparation process and achieve simple process , Improve the structure uniformity, the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: The precursor alloy composition is Fe 65 Ru 5 B 30

[0039] Step 1: Prepare master alloy ingot

[0040] Select Fe, Ru, and B raw materials with a purity of not less than 99% by weight to weigh the ingredients according to the proportion of the precursor alloy; smelt the weighed raw materials in a vacuum arc melting furnace under an argon atmosphere to obtain a uniform composition. master alloy ingot;

[0041] Step 2: Preparation of Alloy Strips

[0042] Under an argon atmosphere, the melted master alloy ingot was sprayed onto a high-speed rotating copper roller by using a single-roll strip stripping device to obtain an alloy strip with a width of 1 mm and a thickness of 20 μm.

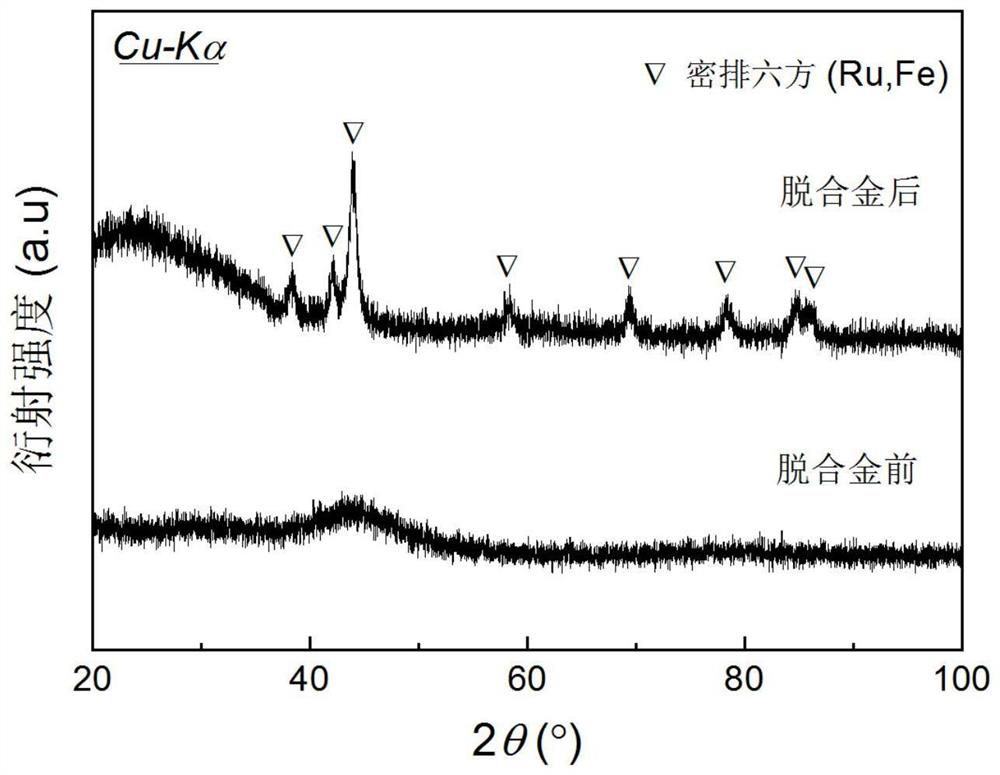

[0043] The phase structure of the alloy strips was detected by X-ray diffractometer (XRD). as attached figure 1 As shown, the XRD results show that the quenched alloy strips have a completely amorphous structure;

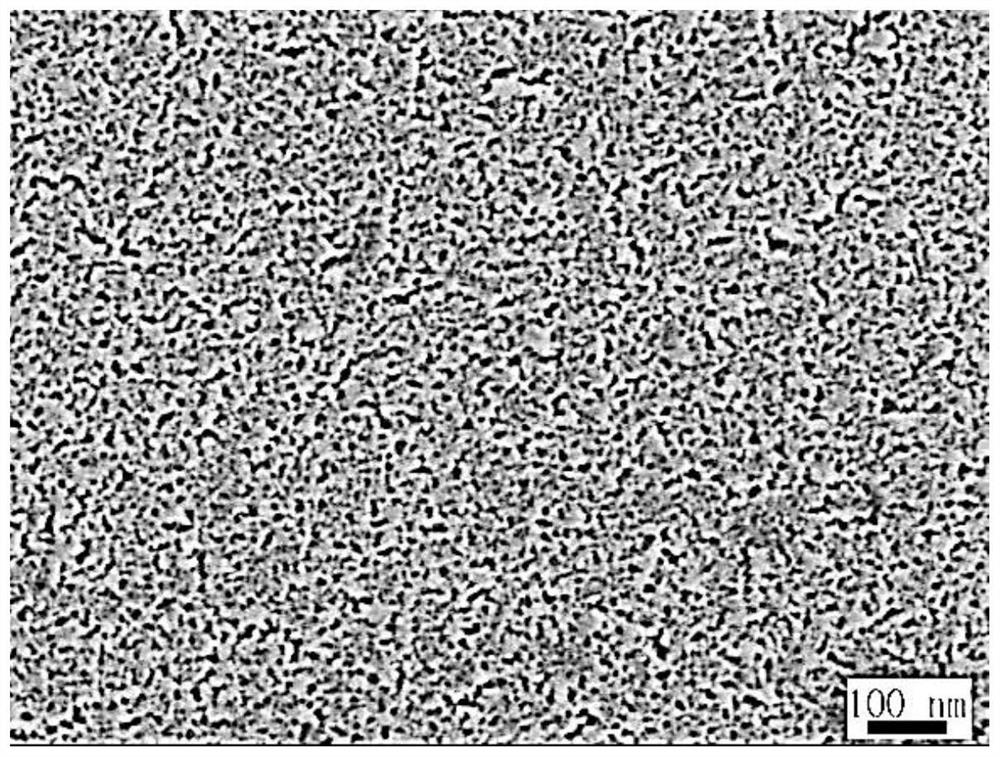

[0044] Step 3: Preparation of nanoporous Ru-Fe alloy by electr...

Embodiment 2

[0049] Example 2: The precursor alloy composition is Fe 75 Ru 5 B 20

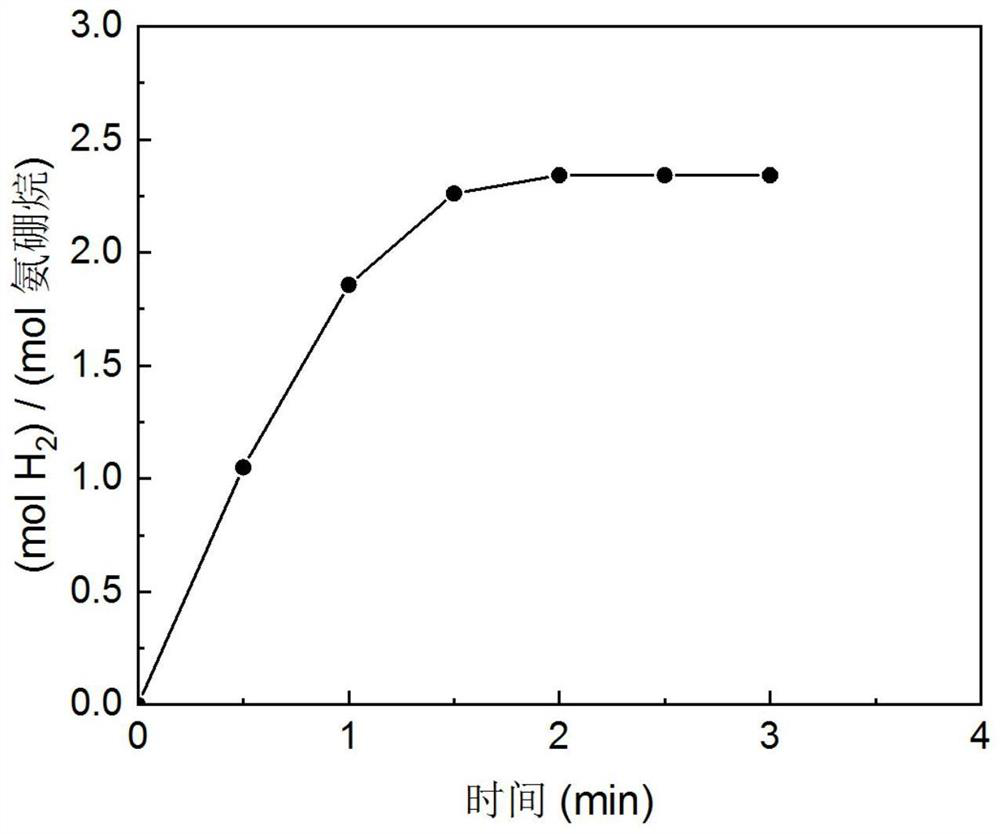

[0050] The preparation of precursor alloy and nanoporous alloy and the test method of catalytic performance are the same as in Example 1. The protective gas used in steps 1 and 2 is a nitrogen atmosphere, and the prepared amorphous precursor alloy strip has a width of 1 mm and a thickness of 25 μm. The dealloying solution is H + A hydrochloric acid solution with a concentration of 1mol / L has a constant potential of -0.20V and a temperature of 80°C. The d of the nanoporous alloy prepared after dealloying is 6nm, l is 20nm, and the chemical composition of the alloy is Ru 50 Fe 50 . TOF is 31mol H 2 mol -1 Rumin -1 . The specific data are listed in Appendix Table 1.

Embodiment 3

[0051] Embodiment 3: the precursor alloy composition is Fe 65 Ru 15 B 20

[0052] The preparation of precursor alloy and nanoporous alloy and the test method of catalytic performance are the same as in Example 1. The width of the amorphous precursor alloy strip prepared in the second step is 2 mm, and the thickness is 30 μm. The dealloying solution is H + A sulfuric acid solution with a concentration of 0.5mol / L has a constant potential of 0.15V. The d of the nanoporous alloy prepared after dealloying is 5nm, l is 18nm, and the chemical composition of the alloy is Ru 70 Fe 30 . TOF is 40mol H 2 mol -1 Ru min -1 . The specific data are listed in Appendix Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com