Backlight source, manufacturing method of backlight source and liquid crystal display

A technology of backlight source and line light source is applied in the field of designing liquid crystal display, which can solve the problems affecting the luminous effect of the backlight source, the display effect of the liquid crystal display, the poor flatness of the light-emitting diode 2, the poor straightness of the light-emitting strip plane, etc., so as to improve the display effect. , The effect of improving the coupling efficiency and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

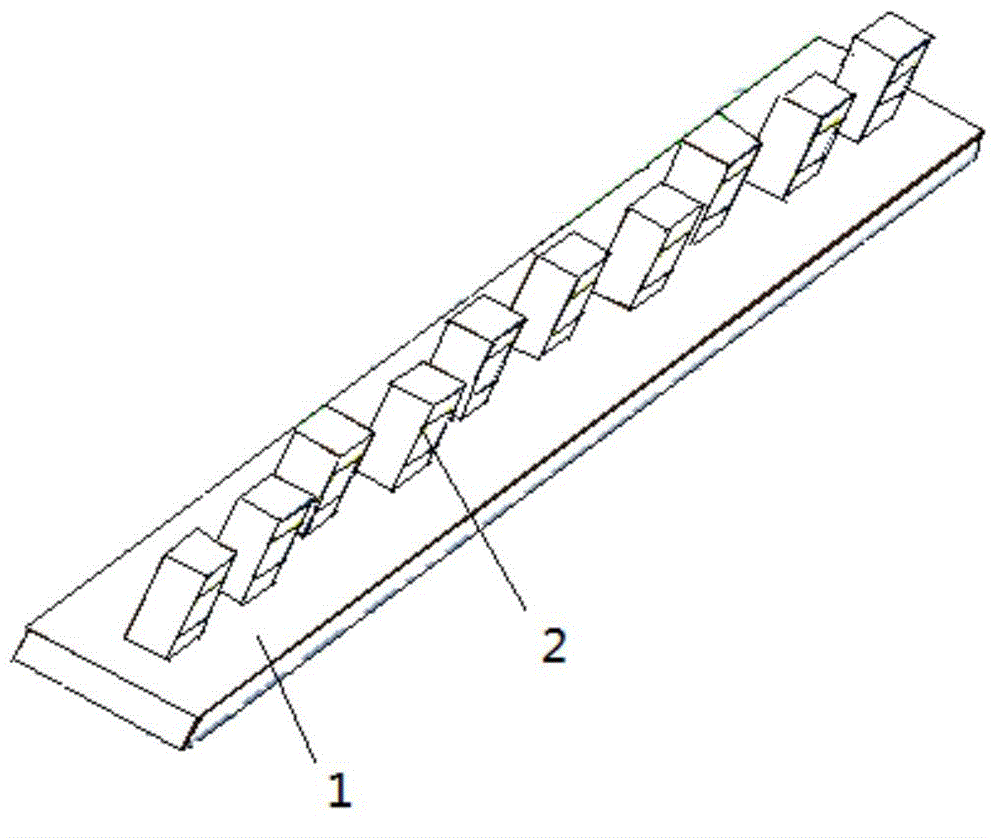

[0023] figure 1 A structural diagram of a backlight source in the prior art is schematically shown. Such as figure 1 As shown, the light emitting diodes 2 on the printed circuit board 1 are relatively dislocated, that is, the flatness of these light emitting diodes 2 is poor.

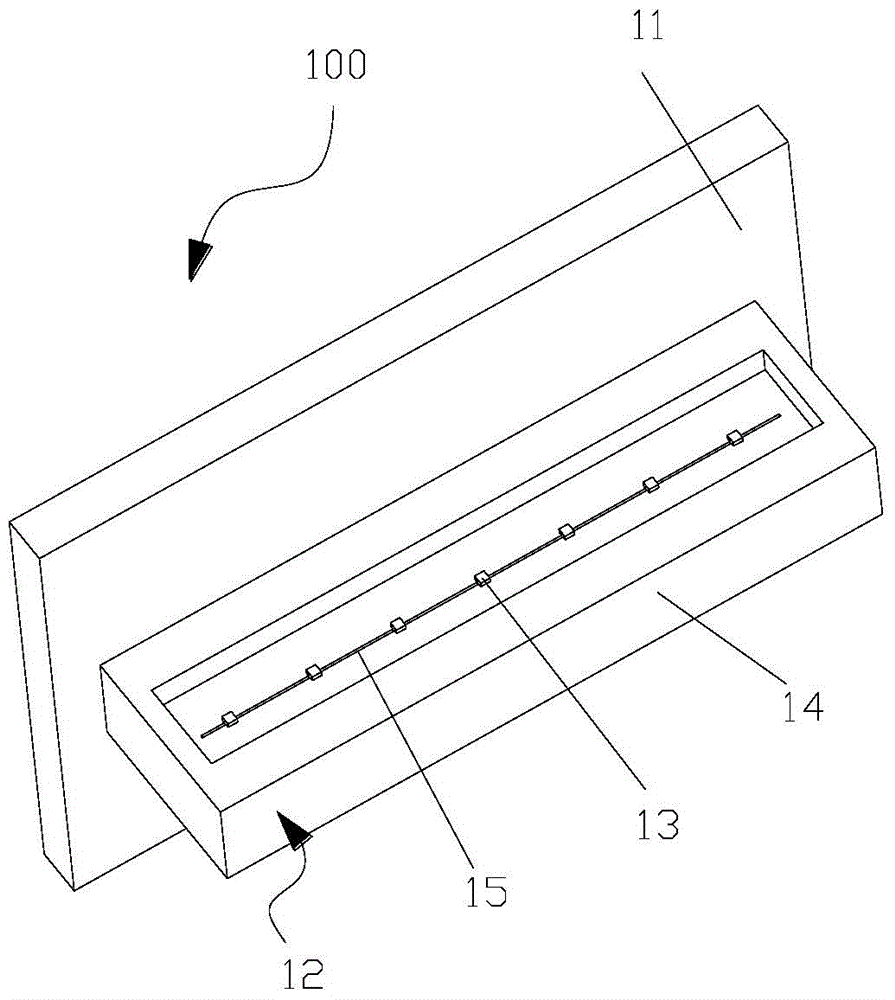

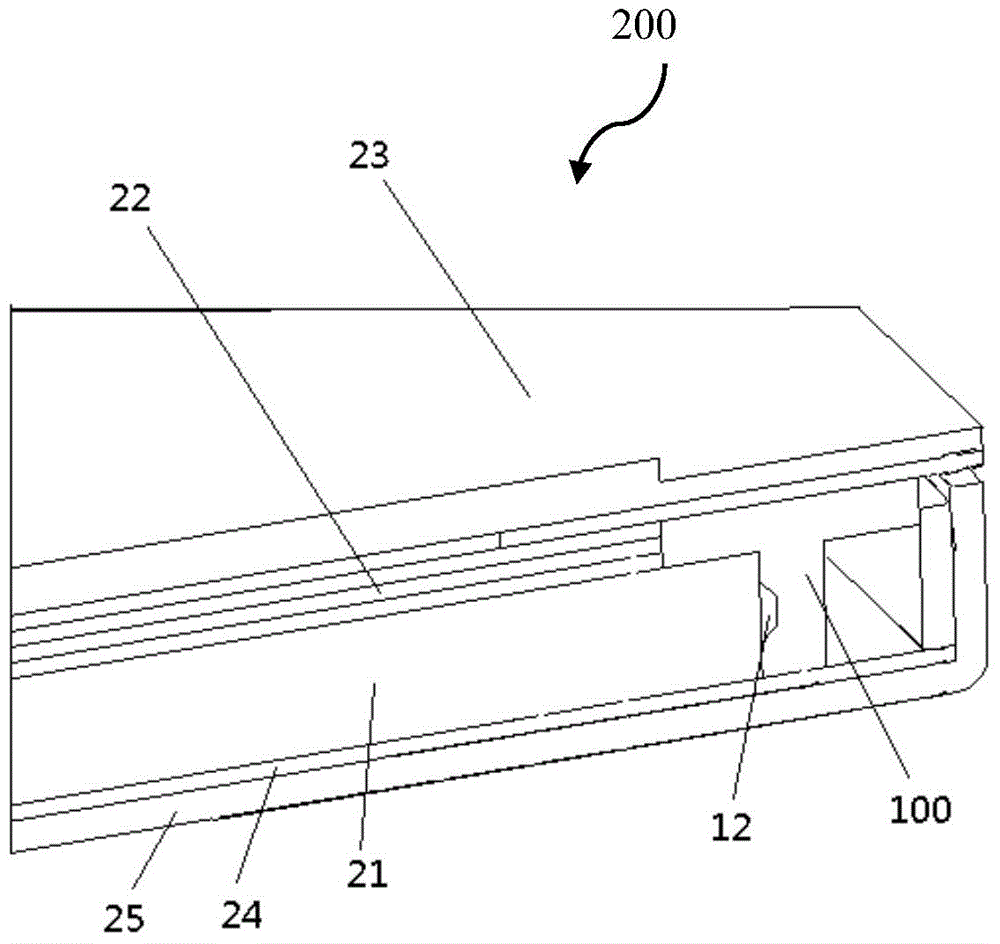

[0024] figure 2 The structure of the backlight source 100 according to the present invention is schematically shown. Such as figure 2 As shown, the backlight source 100 includes a printed circuit board 11 and a line light source 12 disposed on the side of the printed circuit board 11 . The line light source 12 includes an integral module, and multiple point light sources 13 on the same plane are included in the integral module. In one embodiment, the point light sources 13 can be selected as light emitting diodes.

[0025] Specifically, as figure 2 As shown, the linear light source 12 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com