A fully automatic all-in-one machine for hexagonal firecracker cakes

A technology of hexagonal and firecracker cakes, which is applied in the field of fully automatic all-in-one machines, can solve the problems of low production efficiency, inability to produce firecrackers with multi-station automatic integration, difficulty in satisfying fully automatic mechanized production, etc., and achieve fast forming speed, The effect of solving labor shortage and quick maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

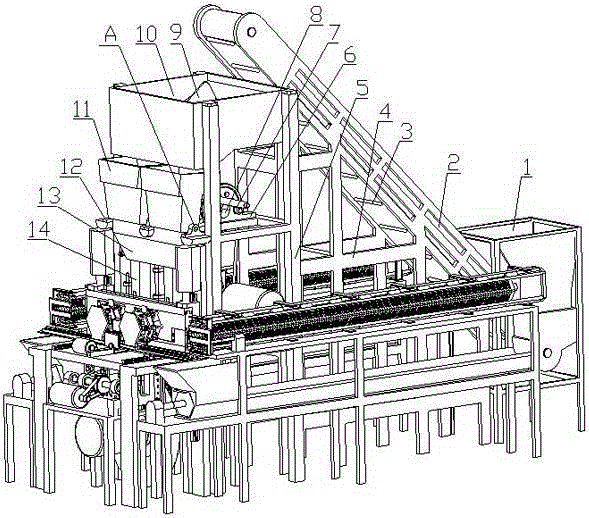

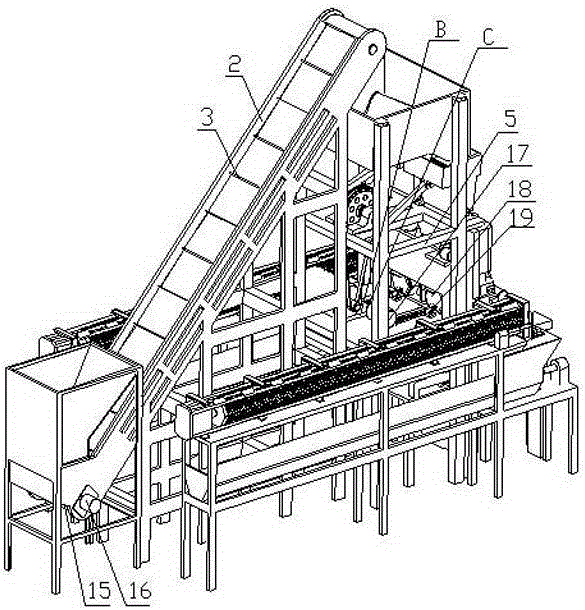

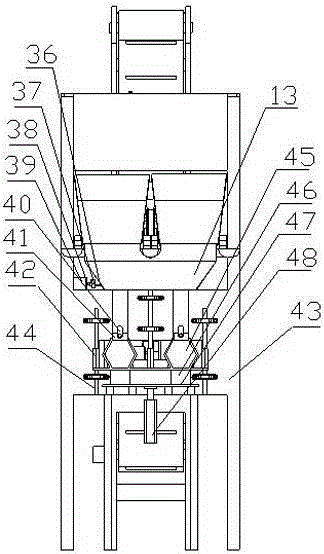

[0027] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a fully automatic all-in-one machine for hexagonal firecracker cakes, including a feeding device, a cake forming device, a clamping device, a bottom sealing device and a cutting device;

[0028] The feeding device comprises a loading hopper 1, a fixed support 4, a conveyor belt 2, a strip baffle 3 and an adjustable motor 16; the loading hopper 1 is arranged on the fixed support 4; the conveyor belt 2 is arranged on the fixed support 4, It is inclined; the tail end of the conveyor belt 2 is arranged below the loading hopper 1; the adjustable motor 16 is arranged at the tail end of the conveyor belt 2 and is connected with the first rolling cylinder 15 on the conveyor belt 2; A strip baffle 3 is provided on the conveyor belt 2;

[0029] Described group cake molding device comprises frame 5, feed hopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com