Sensitive detection unit of nuclear magnetic resonance gyroscope and manufacturing method of the unit

A nuclear magnetic resonance gyroscope and sensitive detection technology, which is applied in the direction of instruments, measuring devices, steering sensing equipment, etc., can solve the problems of low precision of sensitive detection units and cannot meet the requirements of nuclear magnetic resonance gyroscopes, and achieve high practical value, reliable performance, The effect of improving the overall accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

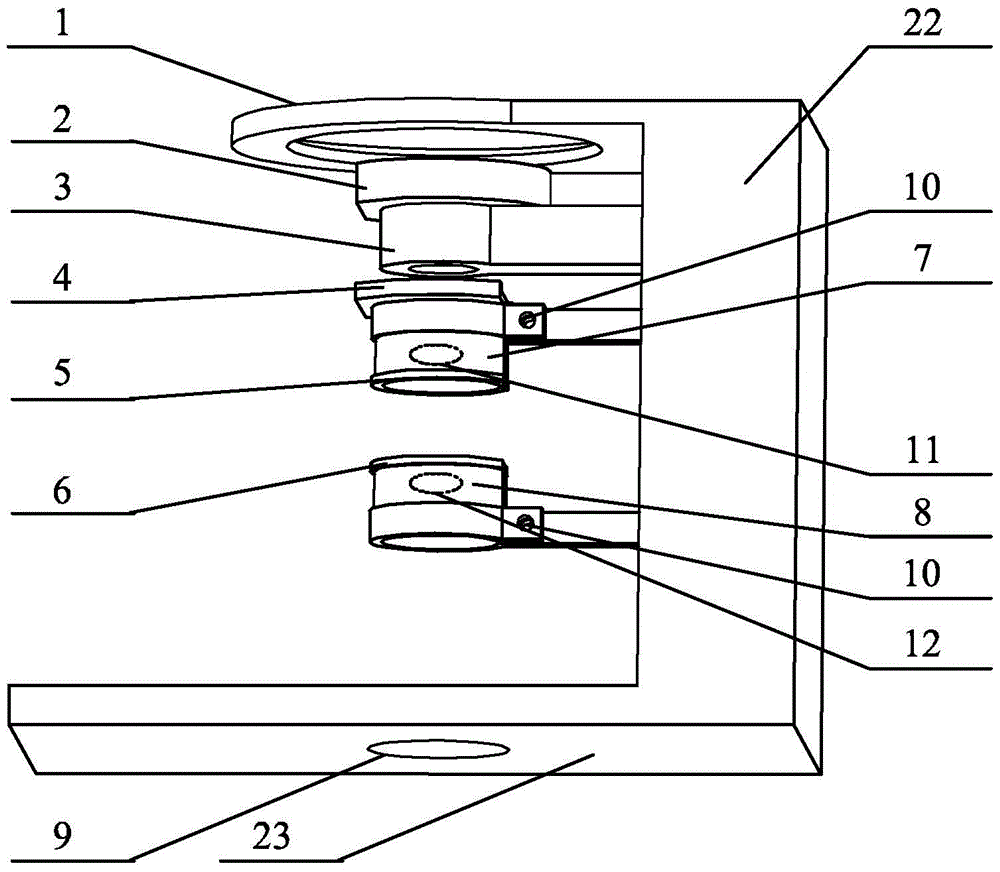

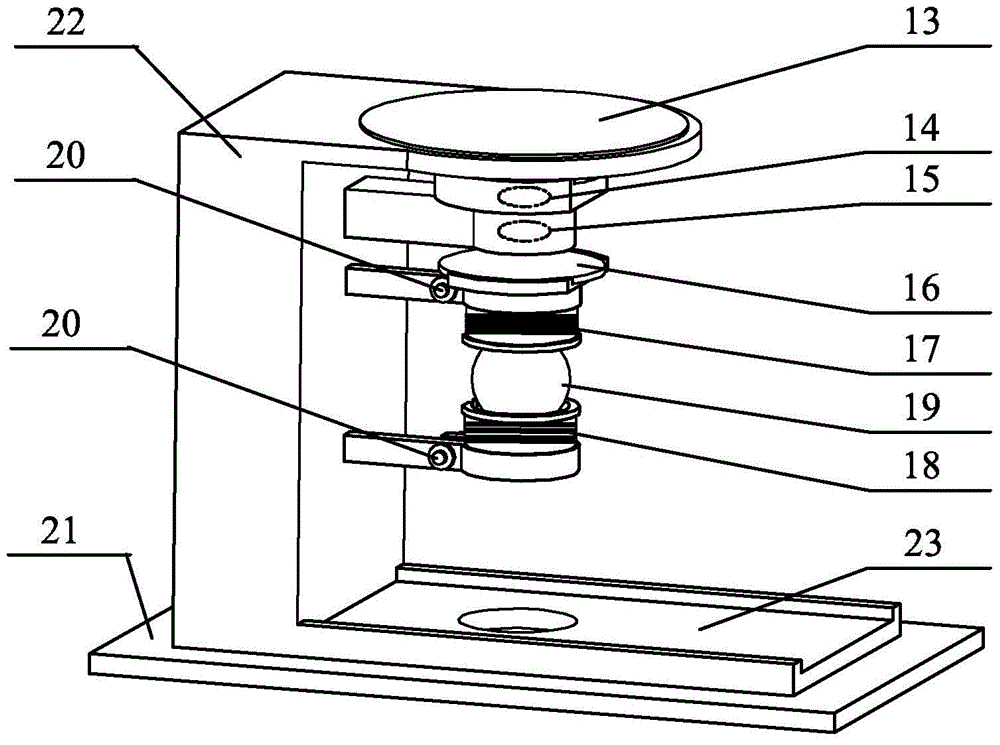

[0014] Specific implementation mode one: refer to figure 1 and figure 2 Specifically illustrate the present embodiment, the nuclear magnetic resonance gyroscope sensitive detection unit described in the present embodiment, it comprises: VCSEL laser device 13, polarizer 14, collimator lens 15, 1 / 4 wave plate 16, nuclear magnetic resonance gas chamber 19, Photodetector 21 and support;

[0015] The bracket includes: column 22, base 23, laser slot 1, polarizer slot 2, collimator lens slot 3, 1 / 4 wave plate slot 4, clamp 5 above the gas chamber, and clamp 6 below the gas chamber;

[0016] The column 22 is vertically fixed on the base 23, and the base 23 is provided with a photodetector light hole 9, a laser slot 1, a polarizer slot 2, a collimator lens slot 3, a 1 / 4 wave plate slot 4, Fixture 5 above the gas chamber and fixture 6 below the gas chamber are sequentially fixed on the column 22 from top to bottom, and laser slot 1, polarizer slot 2, collimator lens slot 3, 1 / 4 wave ...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is a further description of the NMR gyroscope sensitive detection unit described in Embodiment 1. In this embodiment, the bracket is an integrated structure.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is a further description of the NMR gyroscope sensitive detection unit described in Embodiment 1. In this embodiment, the material of the bracket is photosensitive resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com