Checking method and testing system for stop valve rigidity

A detection method, the technology of the stop valve, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, measurement device, mechanical component test, etc., can solve the problems of no detection means, deformation leakage, torsion force and system pressure shock, etc. Achieve the effect of improving the quality of the whole machine and reducing the after-sales failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

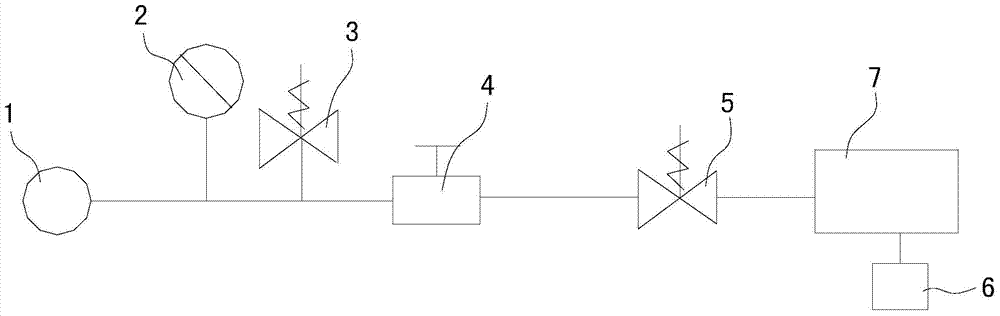

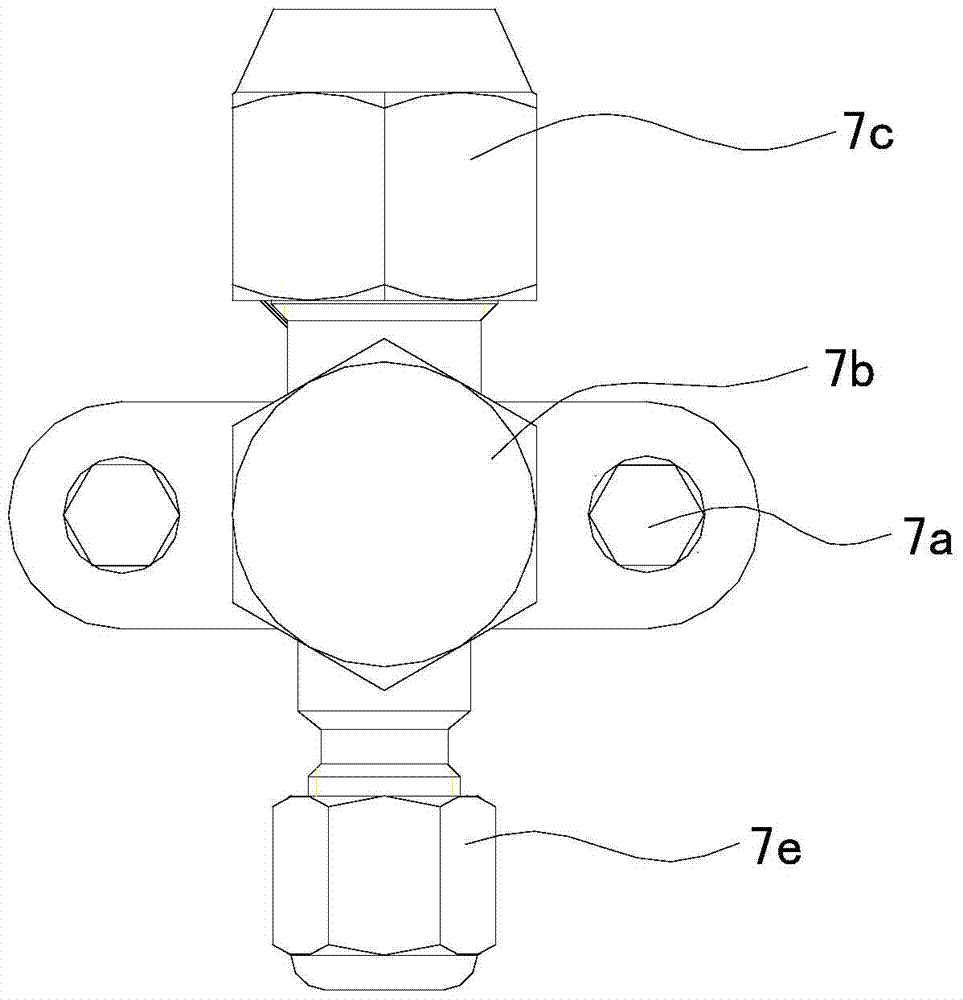

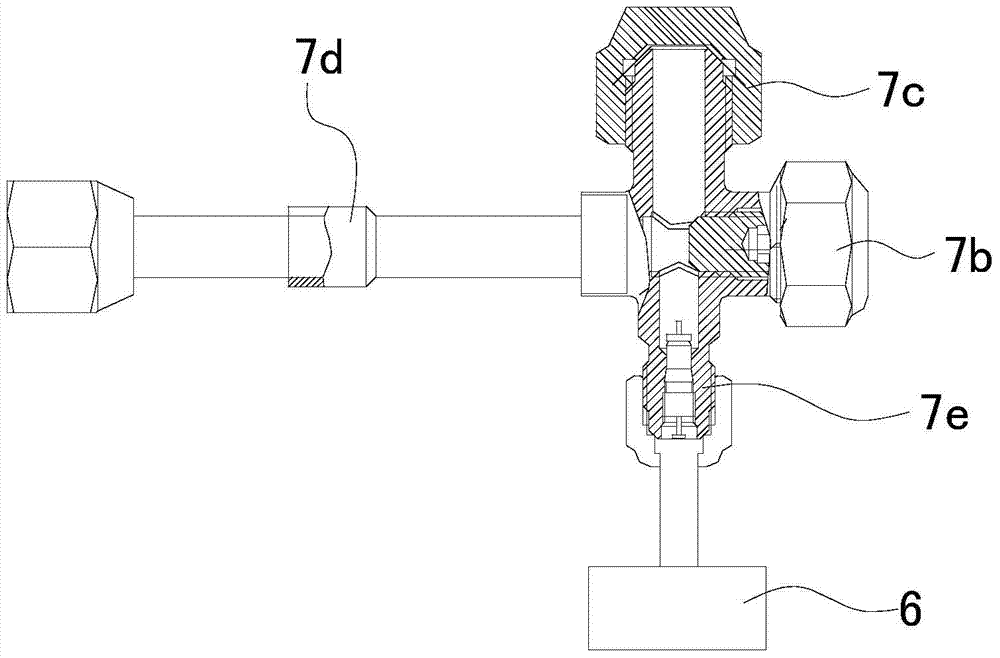

[0028] figure 1 Shown is a schematic diagram of the stop valve rigidity detection system in one of the embodiments of the present invention. The stop valve rigidity detection system includes a workbench (not shown in the figure), an air source 1, an air intake pipeline and a leak detection device 6. Said workbench is used for fixing shut-off valve 7. The gas source 1 is used to provide the high-pressure gas required for the test, and the gas source 1 has a gas outlet. Preferably, the gas source 1 is a nitrogen cylinder. The air inlet pipeline has an air inlet interface for connecting with the air outlet of the air source 1 and an air outlet interface for connecting with the connection end 7d of the shut-off valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com