Multi-station repeated bending test machine

A technology of repeated bending and testing machine, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, and can solve the problems of no repeated bending testing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

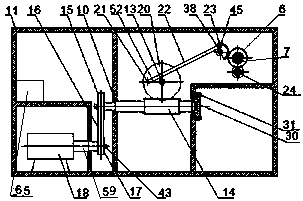

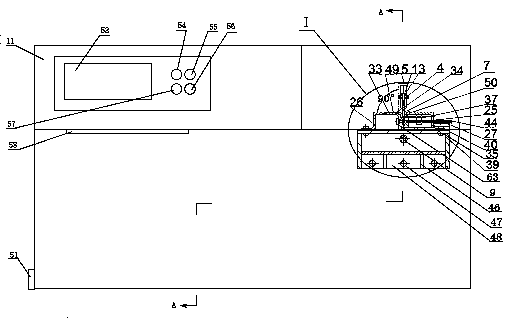

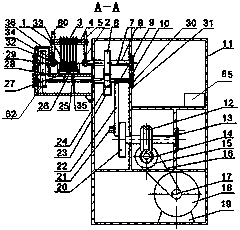

[0020] A multi-station repeated bending testing machine, such as Figure 1-Figure 5As shown, it is characterized in that: the motor 18 is installed on the body 11 with a machine base 19, the motor shaft 59 is fixedly connected with the small pulley 17 through the fastening bolt B43, and the small pulley 17 uses a V-shaped belt 16 and a large pulley 15 Connection, the worm 14 is supported by a bearing 10 and connected with the large pulley 15, the bearing 10 is installed on the body 11, positioned with an end cover 30, the end cover 30 is fixed on the body 11 with a fixing screw 31, the worm 14 is connected with the worm wheel 12, The shaft B13 is supported by the bearing 10, one end is connected to the worm wheel 12, and the other end is connected to the eccentric wheel 20, and one end of the connecting rod 22 is connected with the eccentric wheel 20 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com