Five-position eight-way valve and chromatogram system based on five-position eight-way valve

A five-position eight-way valve and chromatography system technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of reduced life, inconvenient operation, and easy contamination, so as to improve work efficiency and ensure service life , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

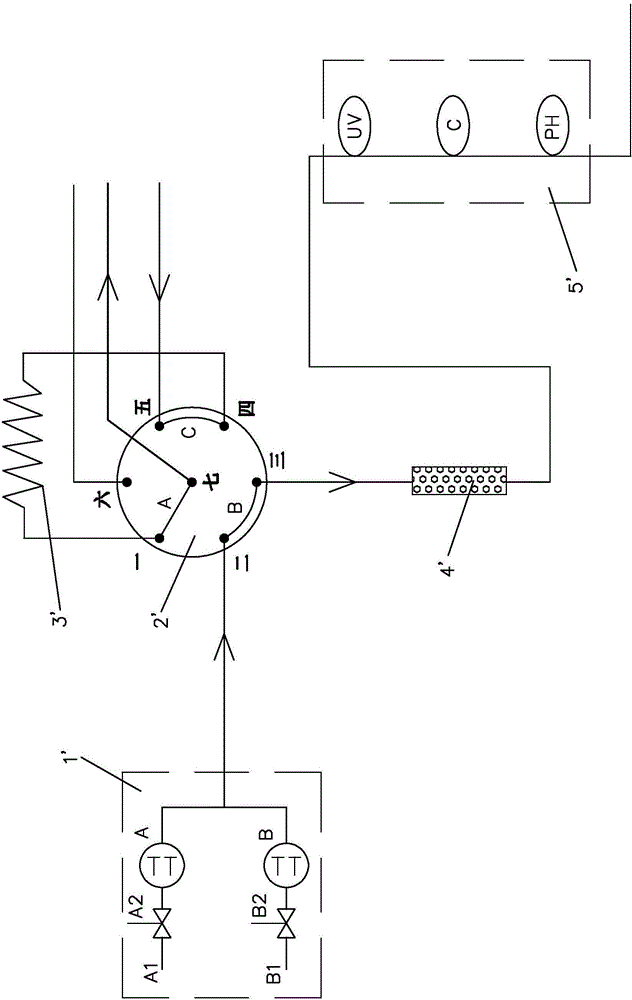

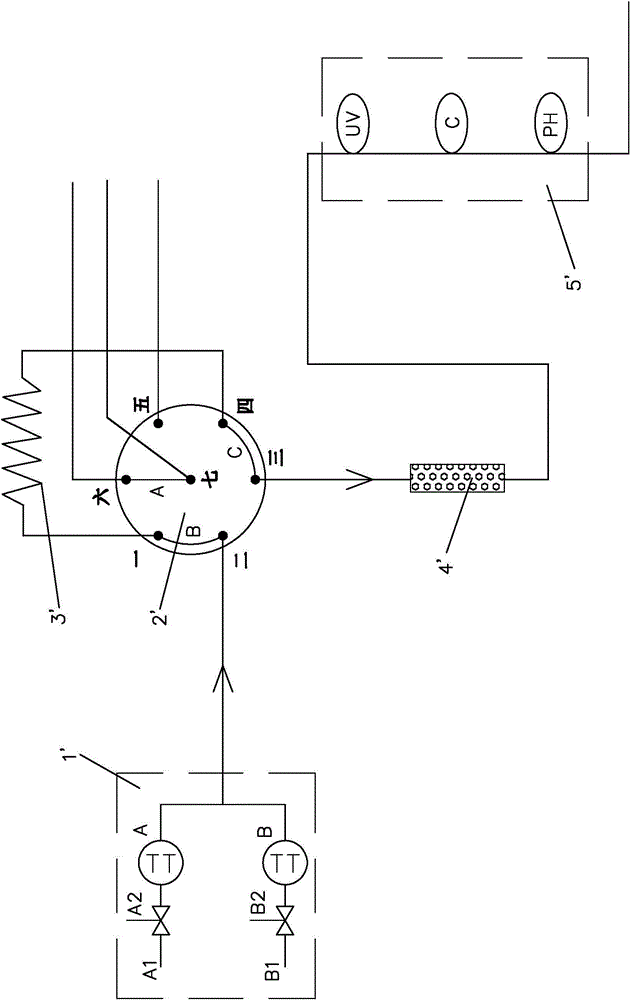

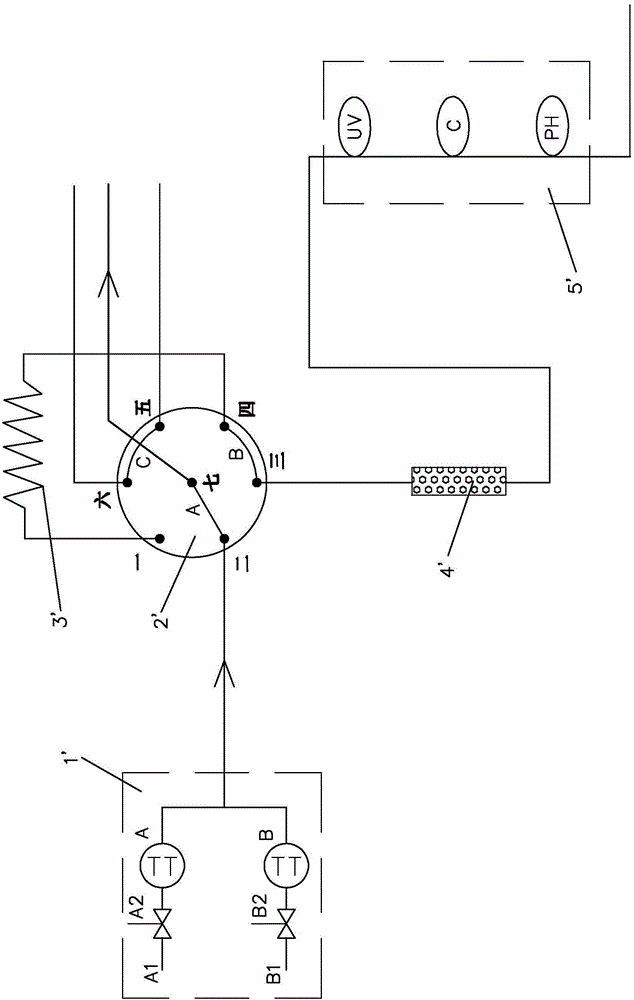

[0035] like Figure 2a As shown, a five-position, eight-way valve of the present invention includes a valve core and a valve body, and the valve body is provided with eight interfaces, which are respectively interface one to interface eight, and the eight interfaces on the valve body are sequentially uniform along the circumferential direction of the valve body Distribution, there are three channels in the spool, which are the first spool channel A, the second spool channel B and the third spool channel C. The spool is located in the valve body and has five positions. At position 1, port 1 and port 2 on the valve body are connected through the first spool channel A, and port 3 and port 7 are connected through the second spool channel B. Port four and port six communicate through the third spool channel C. like Figure 2b As shown, the spool rotates 135° clockwise relative to station 1 so that the spool is at station 2. Port 1 and port 3 on the valve body are connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com