Flowing gas humidity control device

A technology of humidity control and flowing gas, applied in the direction of humidity control, non-electric variable control, control/regulation system, etc., can solve the problems of waste of gas resources, increase of test cost, threat to the safety of test operators, etc., to reduce the risk of leakage Possibilities, reduce test costs, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

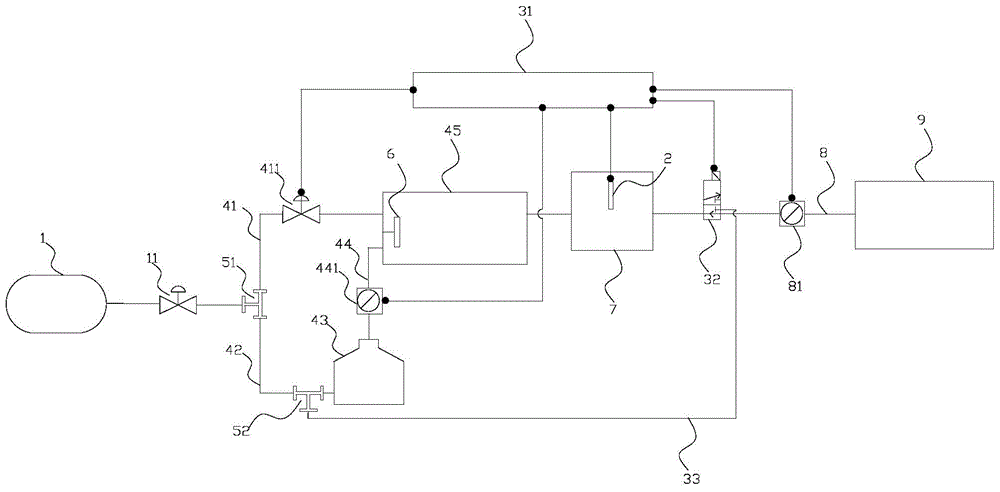

[0018] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the flow gas humidity control device of the present invention includes a gas source 1 and a humidification system for mixing the gas from the gas source 1 into humidified gas for use in the test device 9, It also includes a humidity sensor 2 for detecting the humidity of the humidified gas and a humidification circuit system for returning the humidified gas that has not reached the standard to the humidification system for remixing; the humidified gas formed by the humidification system is transmitted to the test device 9 Humidity sensor 2 is added in the middle, the humidity sensor 2 can monitor the non-standard gas in real time, and the added humidification loop system can return the non-standard gas to the humidification system for re-mixing for test needs. This repeated use reduces the consumption of gas resources. Waste, reduce the test cost, and reduce the possibility o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com