Holographic mirror surface high-grade double-interface wire-winding welding IC card

A dual-interface, holographic technology, applied in the field of electronic information, can solve the problems of not being able to meet the requirements of high-end customers, and the appearance effect is flat, so as to achieve the effect of improving the aesthetic effect, highlighting individuality, and improving grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

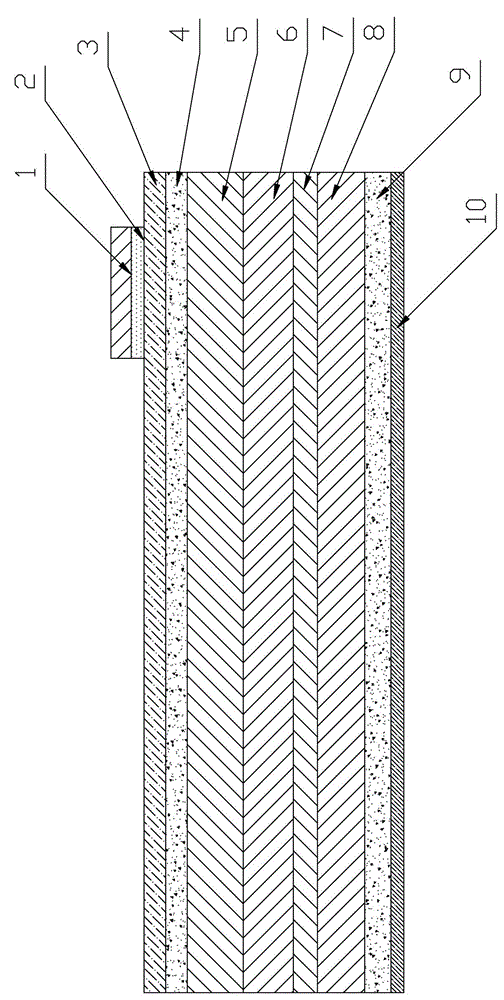

[0014] see figure 1 , 2 , the present invention includes the front adhesive film 3, the front printing layer 4, the front substrate layer 5, the antenna layer 6, the reverse substrate layer 8, the reverse printing layer 9, the reverse adhesive film 10 attached in sequence, and the front adhesive film 3 The outer surface is equipped with a double-interface chip 1 through a hot-melt adhesive tape 2, especially: the front substrate layer 5 and the back substrate layer 8 all adopt a holographic mirror substrate, and the antenna layer 6 and the back holographic mirror substrate An intermediate diaphragm layer 7 is added between the layers; the antenna length×width×spacing×number of turns in the antenna layer 6=81mm×49mm×0.2mm×4 turns.

[0015] In this embodiment, the front adhesive film 3 and the reverse adhesive film 10 are both US KP PVC adhesive film FL2 with a thickness of 0.051 mm.

[0016] The thickness of the holographic mirror substrate described in this embodiment is 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com