Current monitoring type electronic arc-control device

An electronic arc extinguishing and current monitoring technology, which is applied in the electrical field, can solve the problems of poor overload capacity, low reliability, and long conduction time of the arc extinguishing device, and achieve rapid arc extinguishment in the conduction time, improve reliability, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

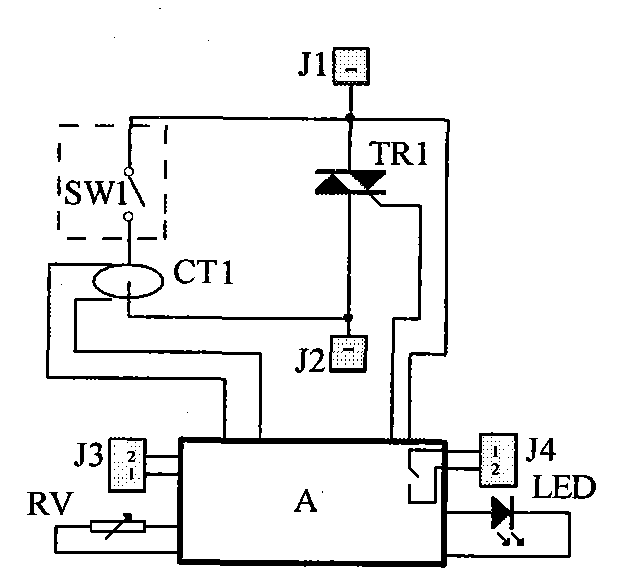

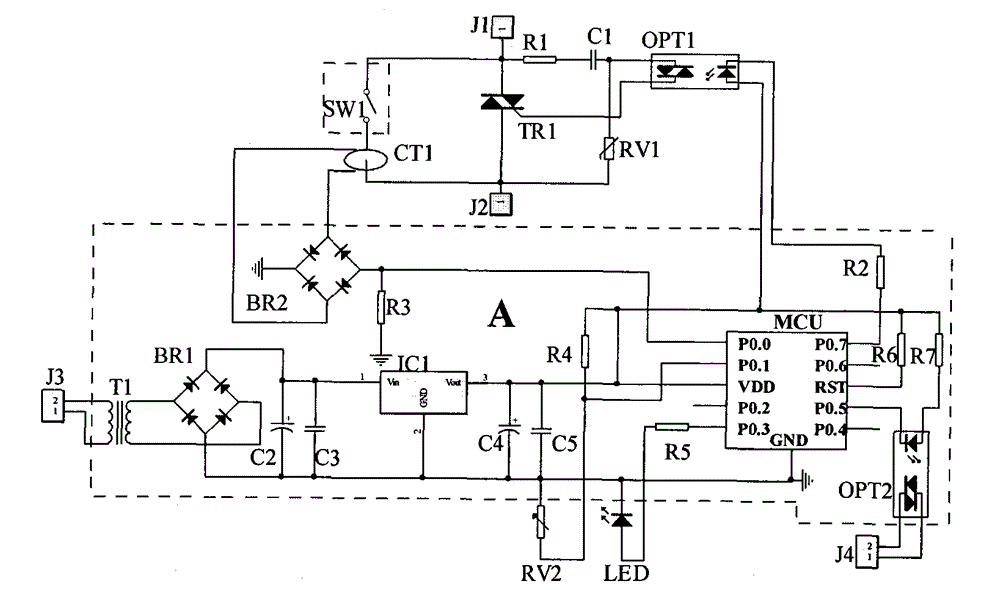

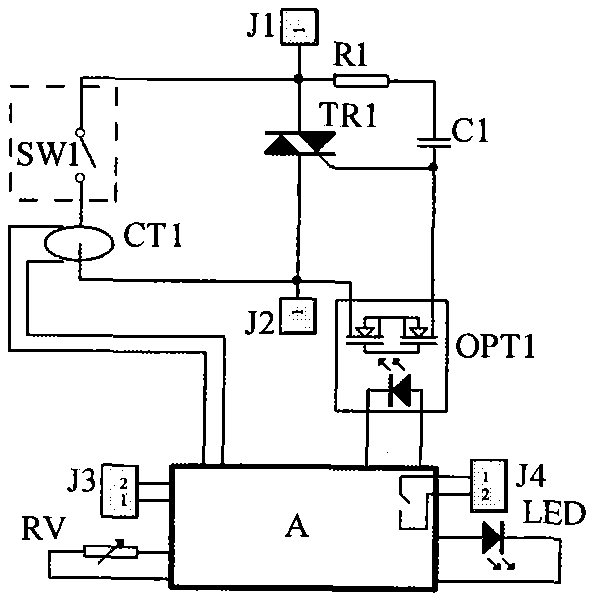

[0029] Such as figure 1 As shown, one of the embodiments of the present invention is a current monitoring electronic arc extinguishing device applied to alternating current, which includes a power semiconductor device TR1 (a thyristor, and a bidirectional thyristor) connected to a mechanical switch SW1, a mechanical switch SW1 A current sensor CT1 is connected (it is a current transformer, the figure shows that the through-heart connection can also be connected in series, and the working principle is the same), the current sensor CT1 is used to detect the current passing through the mechanical switch SW1; the output terminal of the current sensor CT1 and the power semiconductor device The control terminal of TR1 is connected to the control circuit (A), and the mechanical switch connected to this device is the mechanical switch for arc extinguishing required by SW1. The J1 and J2 terminals are the common input and output terminals connected between the power semiconductor device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com