CSP type mems package and production method based on custom lead frame

A lead frame and production method technology, applied in the field of CSP type MEMS packages, can solve the problems of cut-off and distortion of output signals, and achieve the effects of ensuring detection accuracy and eliminating dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

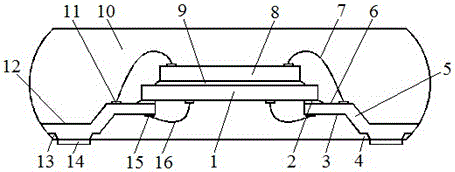

Embodiment 1

[0045]According to customer needs, design multi-row matrix CSP lead frame drawings with different structures and specifications, and make 8-row matrix CSP custom lead frames with no carrier-wing gull-shaped inner pins. The front and back of the inner pins are in addition to electroplated copper. , but also silver-plated; use an 8-inch to 12-inch thinning machine to thin the wafer, the wafer with bumps is thinned to 150 μm, and the wafer without bumps is thinned to 130 μm; during the thinning process The rough grinding speed is 6μm / s, the fine grinding speed is 0.15μm / s, and the polishing speed is 0.05μm / s; at the same time, the anti-warping process is adopted: use A-WD-300TXB dicing machine to scribe the thinned wafer, and scribe During the dicing process, the anti-fragmentation double-knife process is used for scribing, and the dicing feed speed is ≤10mm / s, and the required MEMS IC chip and VGA amplifier chip are formed by cutting and separating; on the chip bonding machine, t...

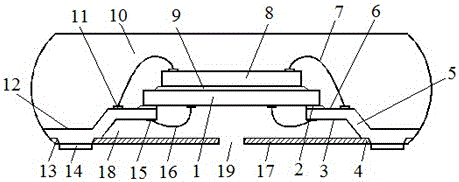

Embodiment 2

[0047] According to the chip and customer needs, design multi-row matrix CSP lead frame drawings with different structures and specifications, and make 16 rows of matrix CSP custom lead frames without carrier-wing gull-shaped inner pins, and remove the electroplating on the front and back of the inner pins In addition to copper, nickel-palladium-gold pads should also be plated; the wafers are thinned using an 8-inch to 12-inch thinning machine, and the wafers with bumps are thinned to 200 μm, and the wafers without bumps are thinned to 155μm; during the thinning process, the rough grinding speed is 6μm / s, the fine grinding speed is 0.15μm / s, and the polishing speed is 0.05μm / s; at the same time, the anti-warping process is adopted: then, the A-WD-300TXB dicing machine is used The wafer is diced, and the anti-fragmentation double-knife process is used for slicing during the slicing process. The slicing feed speed is ≤10mm / s, and the MEMS IC chip and VGA amplifier chip are formed...

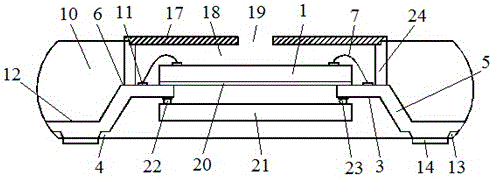

Embodiment 3

[0049] According to the chip and customer needs, design multi-row matrix CSP lead frame drawings with different structures and specifications, and make 12 rows of matrix CSP custom lead frames with no carrier-wing gull-shaped inner pins, and remove the electroplating on the front and back of the inner pins In addition to copper, the UBM metal layer required for flip-chip packaging is also electroplated; the wafer is thinned using an 8-inch to 12-inch thinning machine, and the wafer with bumps is thinned to 175 μm, and the wafer without bumps Thinning to 180 μm; during the thinning process, the rough grinding speed is 6 μm / s, the fine grinding speed is 0.15 μm / s, and the polishing speed is 0.05 μm / s; at the same time, the anti-warping process is adopted: then, A-WD-300TXB dicing machine is used The thinned wafer is diced. During the dicing process, the anti-fragmentation double-knife process is used for slicing. The scribing speed is ≤10mm / s, and the required MEMS IC chip and VG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com