Low-thermoelectrical-potential scanning switch terminal connection mechanism based on flexible printed circuit board

A flexible circuit board, scanning switch technology, applied in the direction of electrical switches, circuits, connections, etc., can solve the problems of many thermoelectric potentials, easy signal interference, complex contact circuits, etc., to simplify the circuit, save direct welding, and avoid the circuit. the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

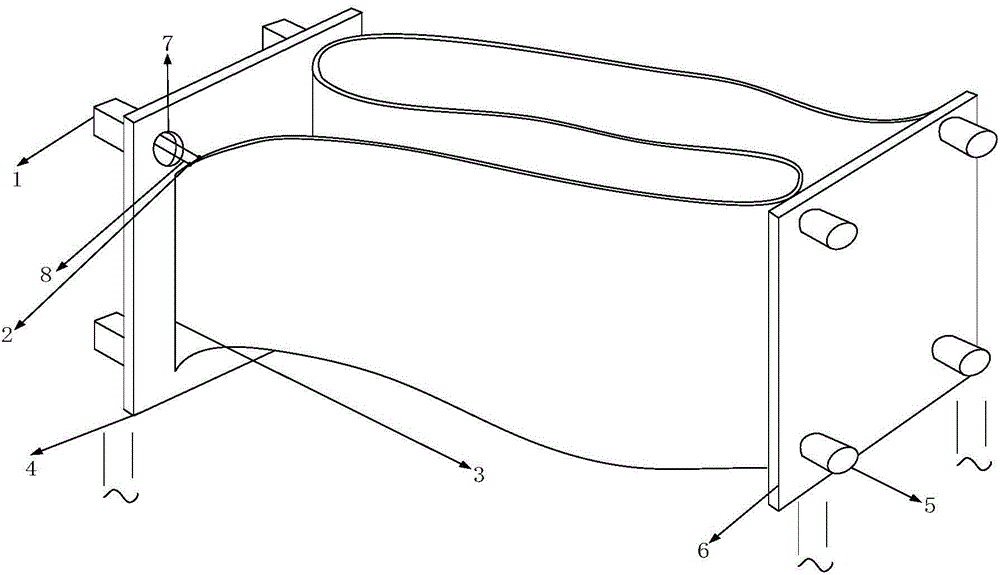

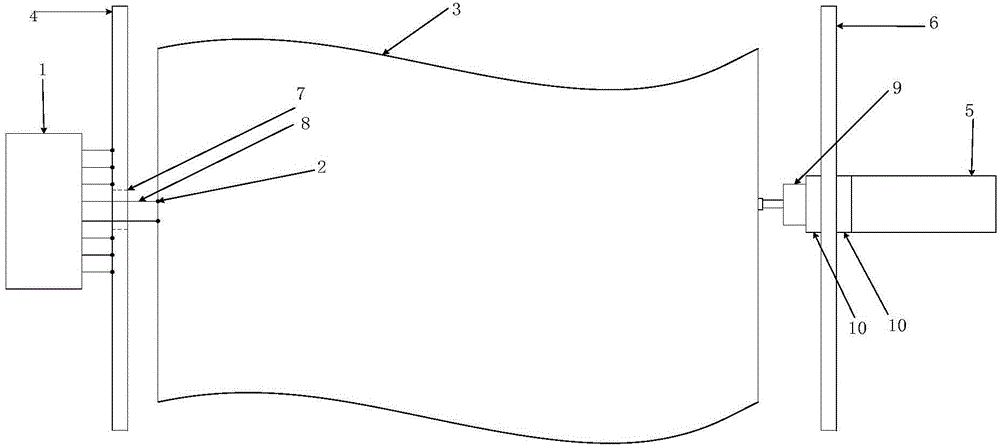

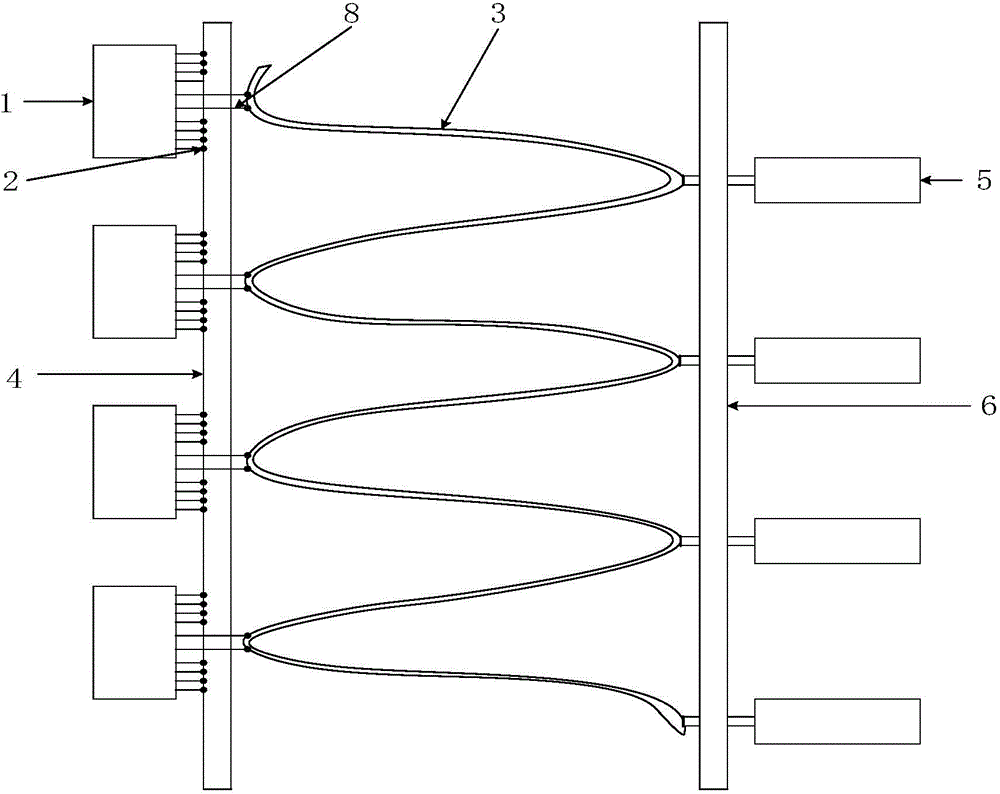

[0022] like figure 1 and figure 2 As shown, the present invention mainly includes the relay to be controlled in the scan switch, the PCB circuit board 4 , the FPC flexible circuit board 3 , the rear panel 6 and the low thermal potential terminal post 5 . like image 3 As shown, a PCB circuit board 4 and a rear panel 6 are respectively installed on both sides of the wave-shaped FPC flexible circuit board 3, and an FPC flexible circuit board 3 is installed between the PCB circuit board 4 and the rear panel 6, and the PCB circuit board 4 is installed with a relay 1, and the two signal pins 8 of the relay 1 are connected to the FPC flexible circuit board 3 through the through slot 7 of the corresponding PCB control circuit board 4, so that the signal pins can pass through it. Solder joint 2 is produced by direct welding between the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com