Pay-off guide device for power

A guiding device and electric power technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as carbon fiber composite core aluminum strand damage, and achieve the effect of reducing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

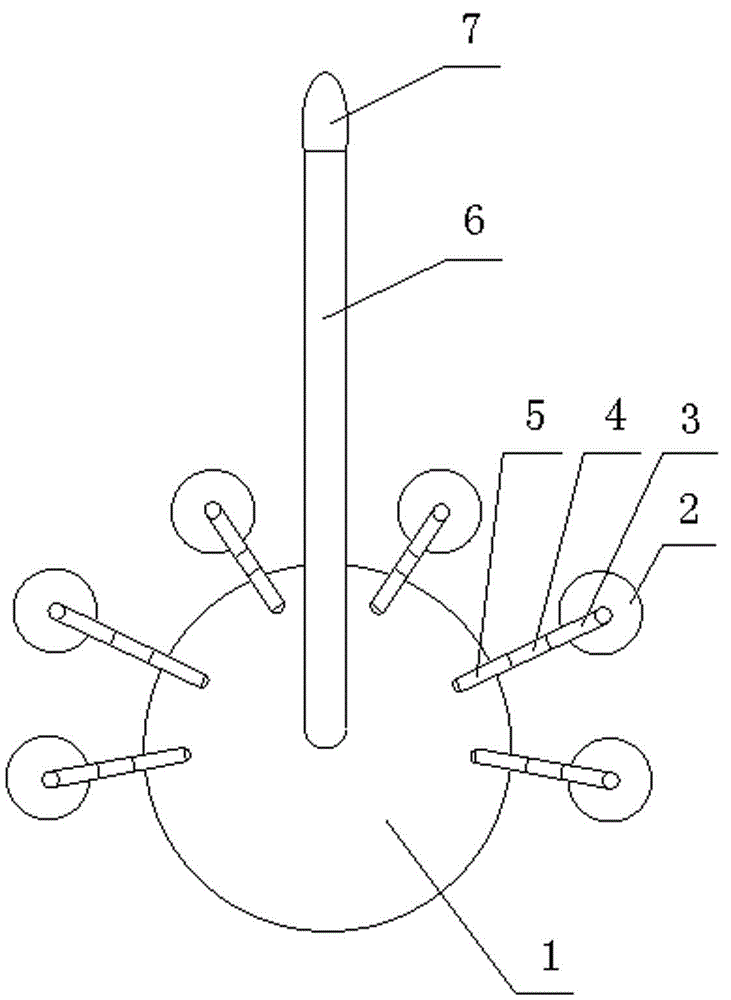

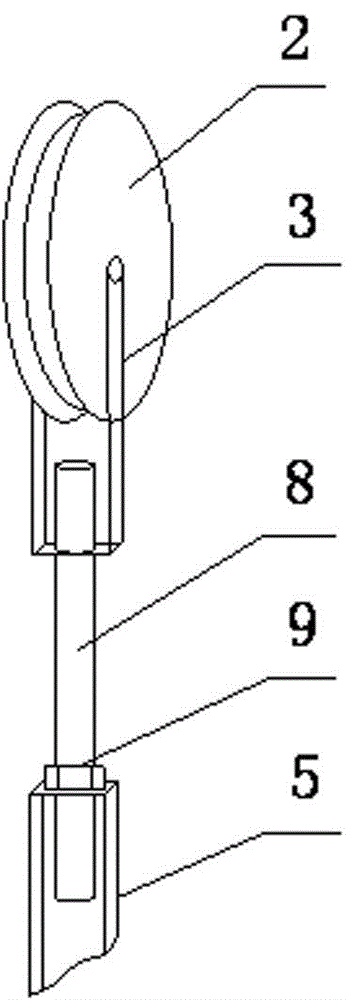

[0009] The structure of the electric power pay-out guide device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] see figure 1 and figure 2 , the electric power pay-off guide device of the present invention comprises a disk 1, a hanging rod 6 is fixed at the center of the disk 1, and a hanging ring 7 is arranged at the other end of the hanging rod 6, and the hanging ring 7 is used to hang the disk 1 on the wire tower superior. On disc 1, a plurality of disc pulley supports 5 are set along its radial direction, and the end of each disc pulley support 5 is provided with an adjusting screw 8 threaded therewith, and nut 9 is established on the adjusting screw 8 . The outer end of each adjusting screw rod 9 is respectively provided with a pulley bracket 3 that is threadedly connected with it, and a pulley 2 is established on each pulley bracket 3, and a smooth layer is laid on the wheel groove surface of each pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com