Automotive glass system capable of automatic defrosting and demisting, defrosting method and demisting method

An automotive glass, automatic technology, applied in the field of defrosting, automotive glass system and defogging, temperature measurement of electric heating glass, can solve problems affecting the appearance and optical performance of the car, improve safety performance and comfort, and enhance user experience Experience and avoid the effect of energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

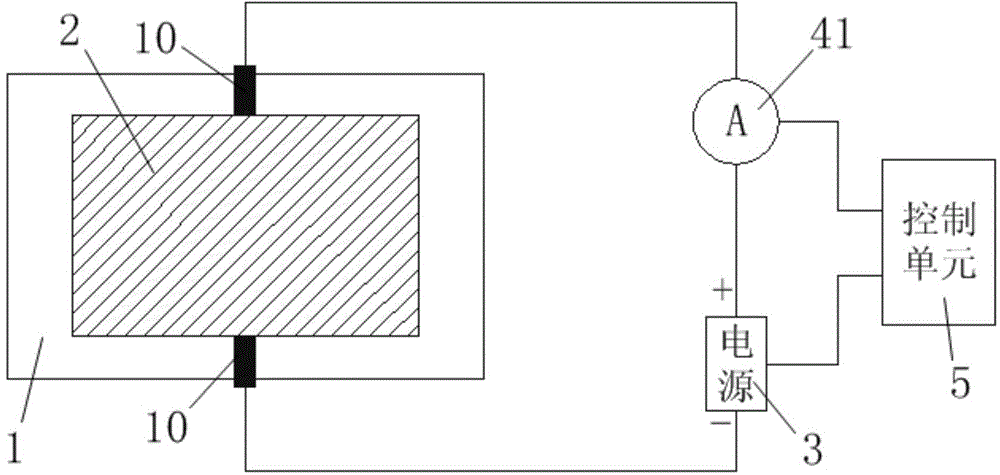

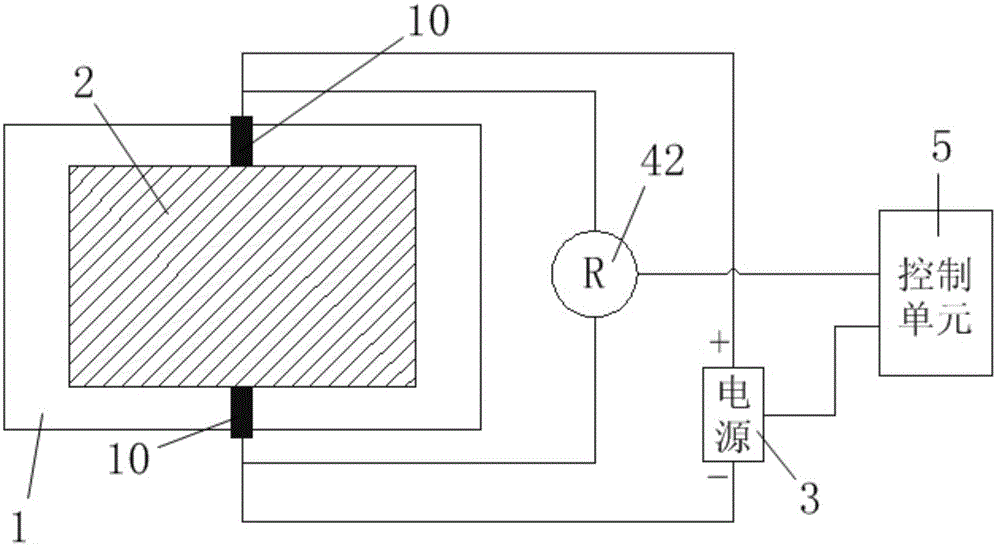

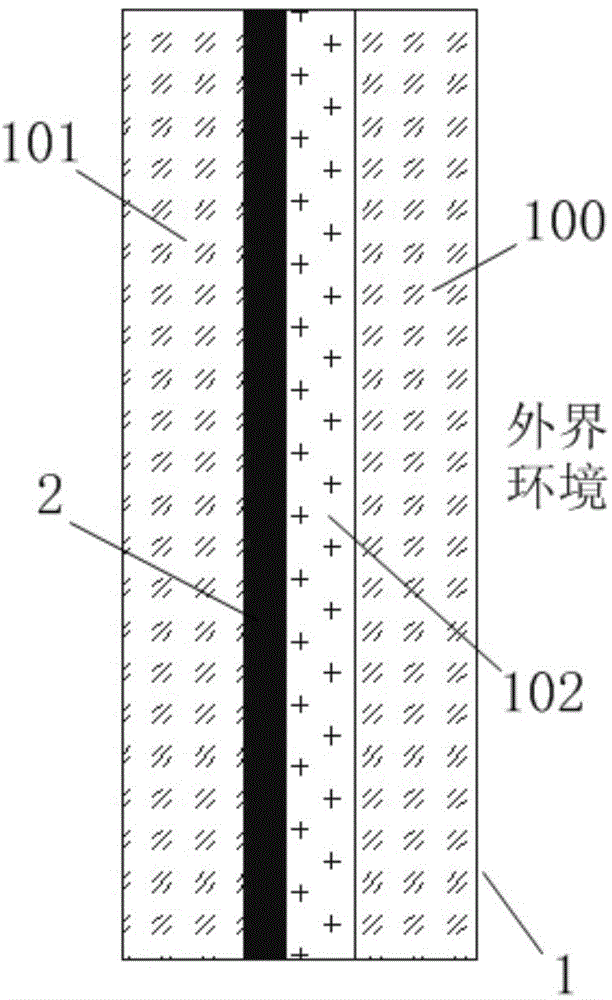

[0051] Such as figure 1 and figure 2 As shown, the temperature measurement system for electrically heated glass of the present invention includes a glass plate 1, an electric heating element 2 and a power supply 3, the electric heating element 2 is arranged on the surface of the glass plate 1, and the electric heating element 2 can be The glass plate 1 is heated by electrification and heating. The power supply 3 can apply a voltage U to both ends of the electric heating element 2. It is characterized in that it also includes a current measuring device or a resistance measuring device. The current measuring device or resistance measuring device can measure the electric heating element 2. Current I or resistance R after energization; In this way, the current or resistance of electric heating element 2 is directly measured by current measuring device or resistance measuring device being directly arranged in the energizing circuit formed by electric heating element 2 and power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com