Method for ameliorating lateral erosion of flexible hollowed-out circuit board

A circuit board and side erosion technology, which is applied in the processing field of flexible hollow circuit boards, can solve the problems of circuit boards being unqualified, unable to be reused, and reduce production efficiency, so as to reduce the occurrence of unqualified products, improve side erosion, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

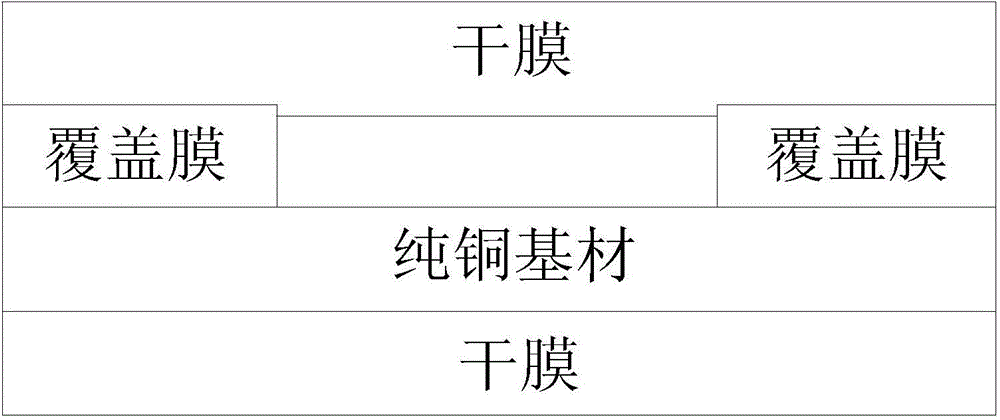

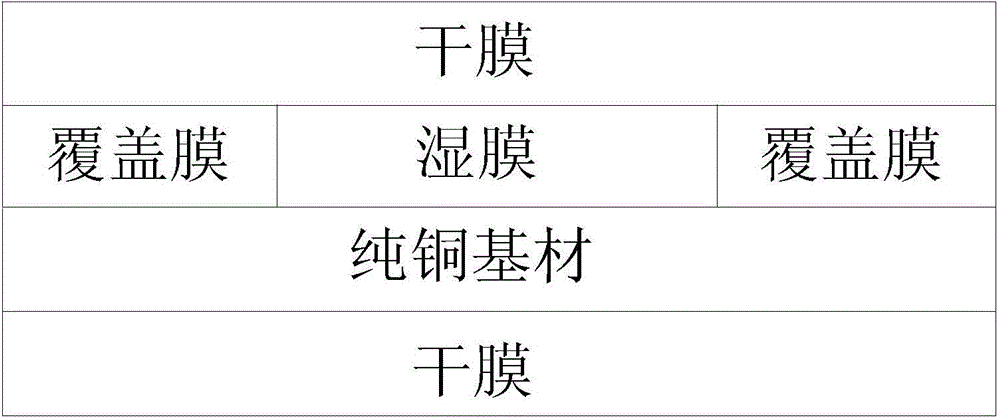

[0014] As shown in the attached figure, it is a method for improving the side erosion of flexible hollow circuit boards. The circuit board first performs the processes of cutting, drilling, and covering film as required, and then prints a wet film on the window opening: according to the circuit board window opening According to the situation of the area, make the corresponding screen printing screen, align the prepared screen printing screen with the circuit board, so that the window of the circuit board is covered, and then print with a wet film. The wet film mentioned here is an anti-etching ink. . After the window opening of the circuit board is completely covered by the anti-etching ink, let it stand for 10 minutes, and then bake at a temperature of 75° C. for 15 minutes to dry the anti-etching ink and evenly cover the window opening of the circuit board.

[0015] In the ensuing etching process, since the window of the circuit board is evenly covered by the anti-etching in...

Embodiment 2

[0017] The difference from Example 1 is that after the window opening of the circuit board is completely covered by the anti-etching ink, it is left to stand for 10 minutes, and then baked at a temperature of 80° C. for 10 minutes.

Embodiment 3

[0019] The difference from Example 1 is that after the window opening of the circuit board is completely covered by the anti-etching ink, it is left to stand for 10 minutes, and then baked at a temperature of 78° C. for 13 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com