Moisturizing and deodorant wet tissue, its processing method and mask comprising the wet tissue

A technology of wet wipes and masks, which is applied in the field of daily chemical industry, can solve the problems of bad smell, high degree of pollution, and affecting the comfort of passengers, and achieve the effect of improving the deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

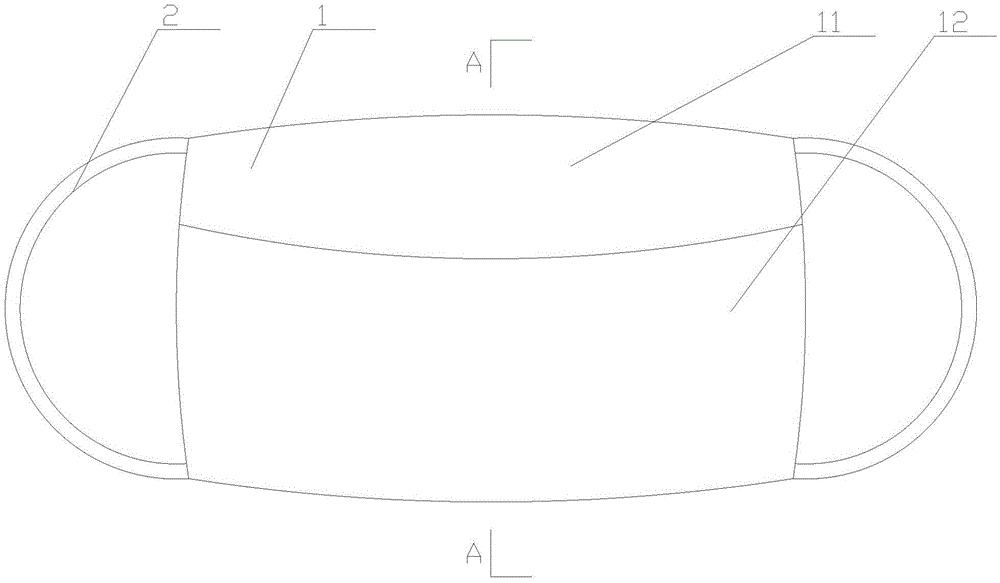

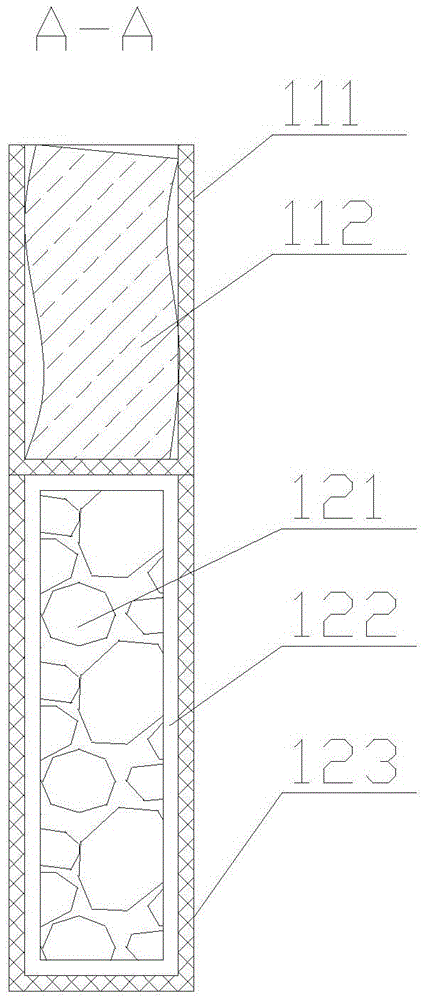

Image

Examples

Embodiment 1

[0051] The wet wipes include a non-woven fabric and a humidifying and deodorant liquid with a weight ratio of 1:3.5, and the humidifying and deodorant liquid is evenly sprayed on the surface of the non-woven fabric, and the humidifying and deodorant liquid is sprayed on the surface of the non-woven fabric according to the Percent by weight includes 70% deionized water, 25% glycerin, 5% sorbitol, 1% plant deodorant, 0.3% potassium sorbate and 0.01% lemon essential oil.

[0052] The humidifying and deodorizing liquid also includes citric acid for adjusting the pH value, so that the pH value of the humidifying and deodorizing liquid is adjusted to 4.

[0053] Process as follows:

[0054] 1) Prepare humidifying and deodorizing liquid:

[0055] 1.1) Add 70 parts of deionized water, 25 parts of glycerin, 5 parts of sorbitol and 0.3 parts of potassium sorbate into the batching kettle, and stir until completely dissolved;

[0056] 1.2), add 1 part of plant deodorant to the batching ...

Embodiment 2

[0063] The wet wipes include a non-woven fabric and a humidifying and deodorant liquid with a weight ratio of 1:4.5, and the humidifying and deodorant liquid is evenly sprayed on the surface of the non-woven fabric, and the humidifying and deodorant liquid is sprayed on the surface of the non-woven fabric according to Percent by weight includes 50% deionized water, 32% glycerin, 15% sorbitol, 3% plant deodorant, 0.8% potassium sorbate and 0.05% lemon essential oil.

[0064] The humidifying and deodorizing liquid also includes citric acid for adjusting the pH value, so that the pH value of the humidifying and deodorizing liquid is adjusted to 5.

[0065] Process as follows:

[0066] 1) Prepare humidifying and deodorizing liquid:

[0067] 1.1) Add 50 parts of deionized water, 32 parts of glycerin, 15 parts of sorbitol and 0.8 parts of potassium sorbate into the batching kettle, and stir until completely dissolved;

[0068] 1.2), add 3 parts of plant deodorant to the batching k...

Embodiment 3

[0075] The wet wipes include a non-woven fabric and a humidifying and deodorant liquid with a weight ratio of 1:4, and the humidifying and deodorant liquid is uniformly sprayed on the surface of the non-woven fabric, and the humidifying and deodorant liquid is sprayed on the surface of the non-woven fabric according to Percent by weight includes 60% deionized water, 28% glycerin, 10% sorbitol, 2% plant deodorant, 0.55% potassium sorbate and 0.03% lemon essential oil.

[0076] The humidifying and deodorizing liquid also includes citric acid for adjusting the pH value, so that the pH value of the humidifying and deodorizing liquid is adjusted to 4.5.

[0077] Process as follows:

[0078] 1) Prepare humidifying and deodorizing liquid:

[0079] 1.1) Add 60 parts of deionized water, 28 parts of glycerin, 10 parts of sorbitol and 0.55 parts of potassium sorbate into the batching kettle, and stir until completely dissolved;

[0080] 1.2), add 2 parts of plant deodorant to the batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com