Filtering medium used for air cleaning, filter core and preparation method of filtering medium

A filter medium and air purification technology, which is applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of poor purification effect of formaldehyde and particulate matter, and achieve the effect of simple method, avoiding damage and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

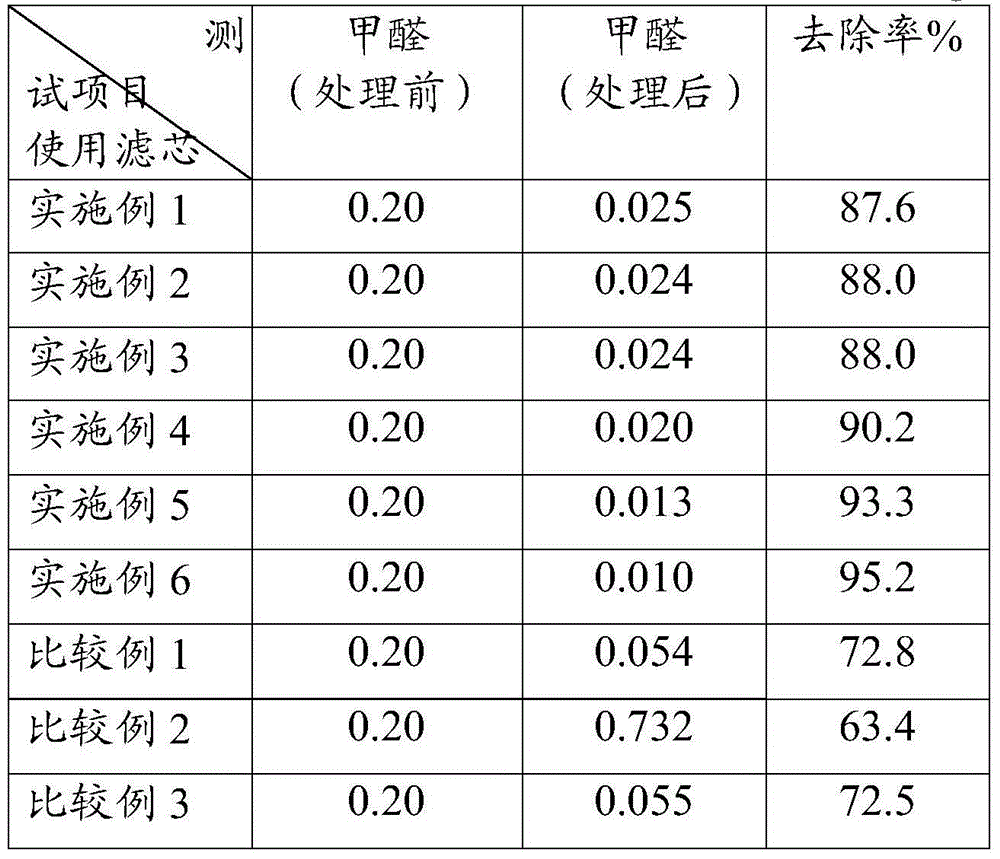

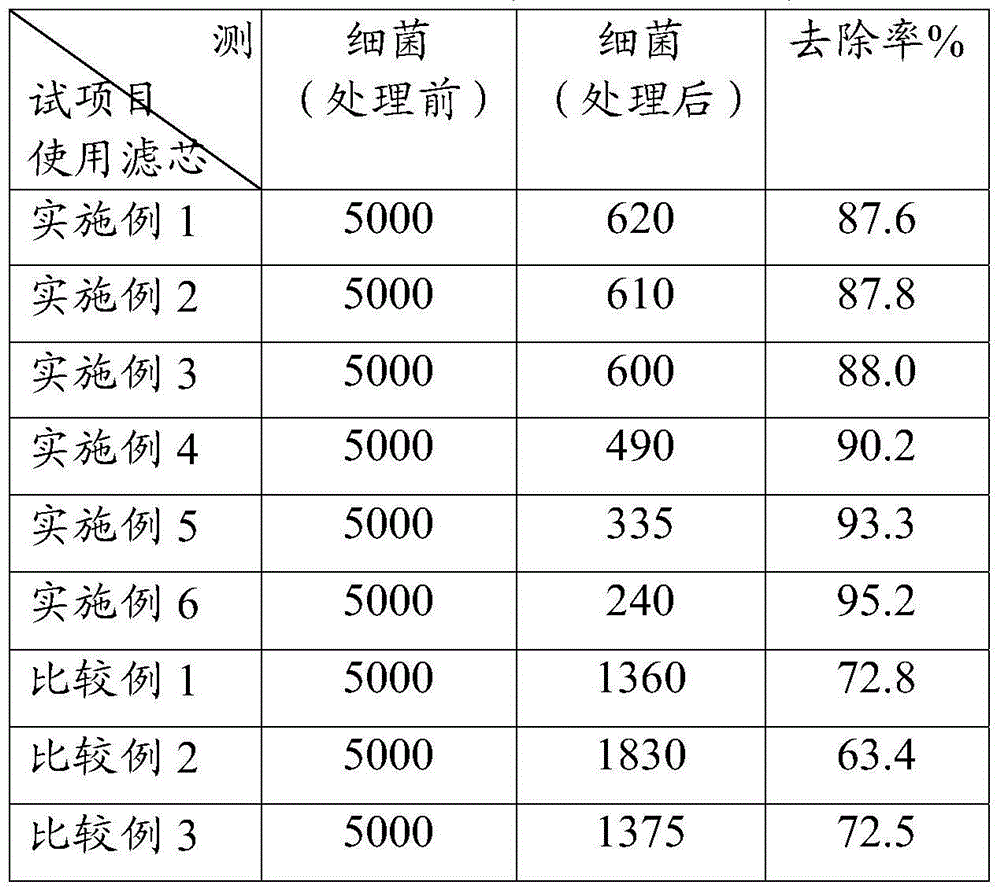

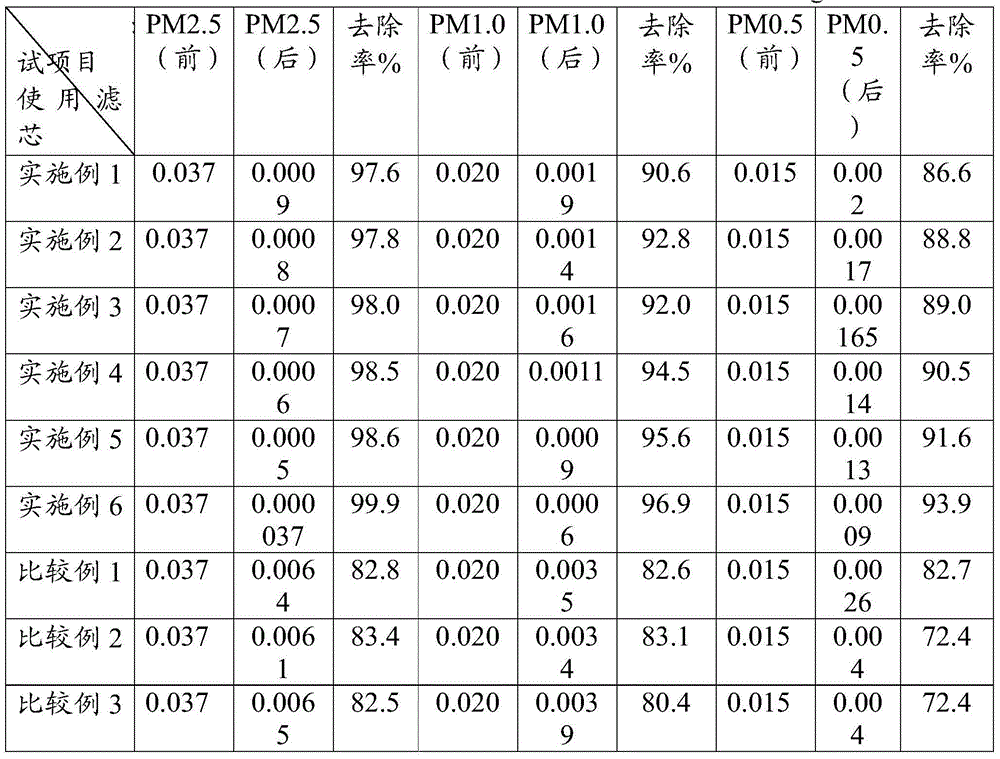

Examples

preparation example Construction

[0018] The invention provides a kind of preparation method for the filter medium of air purification, comprises the following steps:

[0019] a) mixing activated carbon powder, diatomaceous earth and zeolite molecular sieve powder to obtain a mixture, the weight ratio of the activated carbon powder, diatomite and zeolite molecular sieve powder is 100~300:100~200:100~200;

[0020] b) pressing, sintering and cooling the mixture obtained in step a) in a mould.

[0021] The present invention first mixes activated carbon powder, diatomite and zeolite molecular sieve powder to obtain a mixture, and the weight ratio of the activated carbon powder, diatomite and zeolite molecular sieve powder is 100~300:100~200:100~200; preferably 130 ~280:120~180:120~180; more preferably 150~250:140~160:140~160.

[0022] In the present invention, activated carbon is a porous material with honeycomb pore structure, large specific surface area, specific surface functional groups, stable physical and c...

Embodiment 1

[0050] (1) Take hydrochloric acid modified diatomite 100g;

[0051] (2) Take medical active carbon powder 100g, the specific surface area of described medical active carbon is 800m 2 / g;

[0052] (3) Take by weighing 100g of 13X zeolite molecular sieve powder;

[0053] (4) Put the above three powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0054] (5) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.7 MPa, and sinter at a temperature of 260° C. for 120 minutes;

[0055] (6) Cool naturally to 50° C. and then release the mold with a siloxane uranium release agent to obtain a columnar filter element.

[0056] The prepared filter element has a diameter of 400 mm and a length of 200 mm.

Embodiment 2

[0058] (1) Take diatomite 150g;

[0059] (2) Take by weighing medical active carbon powder 200g, the specific surface area of described medical active carbon is 800m 2 / g;

[0060] (3) Take by weighing 150g of 4a zeolite molecular sieve powder;

[0061] (4) Put the above three powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0062] (5) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.6MPa, and sinter at a temperature of 280° C. for 130 minutes;

[0063] (6) Cool naturally to 50° C. and then release the mold with a siloxane uranium release agent to obtain a plate-shaped filter element.

[0064] The prepared filter element has a length of 400 mm, a width of 300 mm, and a thickness of 200 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap