Gas sulfur trioxide continuous sulfonation production plant

A technology for sulfur trioxide and production equipment, which is applied in chemical/physical/physical chemical processes, organic chemistry, sulfonate preparation, etc., and can solve problems such as large fluctuations in product quality, low production efficiency, and low utilization rate of sulfur trioxide. , to achieve the effect of stable product quality, improved utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

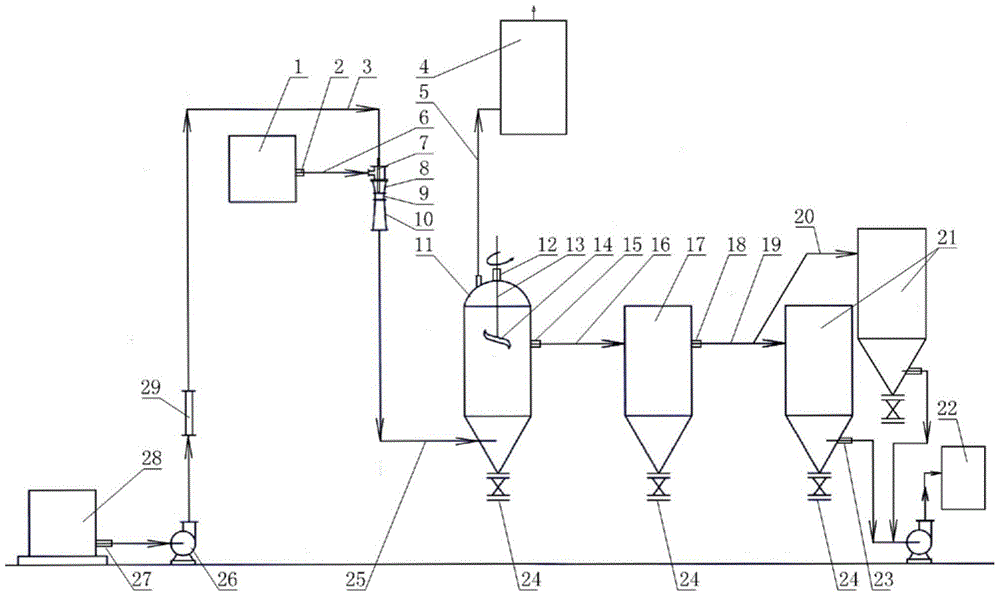

[0008] The gas sulfur trioxide continuous sulfonation production device of the present invention can also be called a gas-liquid phase multiple reactor or a Venturi tank group continuous sulfonation device. Two different types of reactors are effectively combined to form a whole. This combined reactor can be referred to as a composite reactor or a compound reactor. In the present invention, a Venturi tube reactor and A tank reactor is effectively grouped together. Concrete embodiment is as follows: gaseous sulfur trioxide continuous sulfonation production device, has sulfur trioxide generating device 1, raw material storage tank 28, absorption tower 4, and the key point of the design of the present invention is, also has Venturi tube reaction in the device Device, tank reactor, reactant first storage tank 17 and reactant second storage tank 21, described Venturi tube reactor is made of throat 9, shrinkage tube 8 and diffusion tube 10, wherein throat is The straight pipe, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap