A self-propelled straw processing machine

A processing machine and self-propelled technology, which is applied in the direction of presses, agricultural machinery and tools, and material forming presses, etc., can solve the problems of insufficient packing strength, failure to achieve one-step completion, high freight costs, etc., and achieve the effect of huge market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

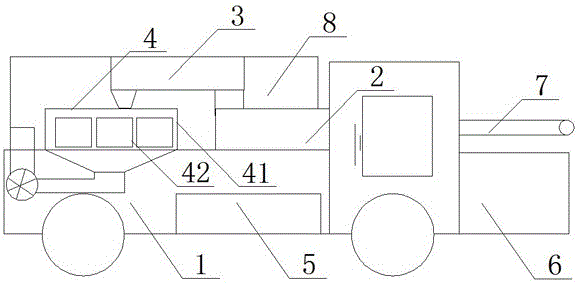

[0021] Such as figure 1 , 2 A self-propelled straw processing machine shown in 3, comprising a body 1 with wheels or crawlers, a crushing device 2, a heating and drying device 3, and an extruding device 4, which are installed on the body and connected sequentially, are installed on the body and The above-mentioned device is connected with a power source 5 that provides power; the body is also provided with a traction nose 6, and the traction nose 6 includes a driving control room and an engine installed in the nose.

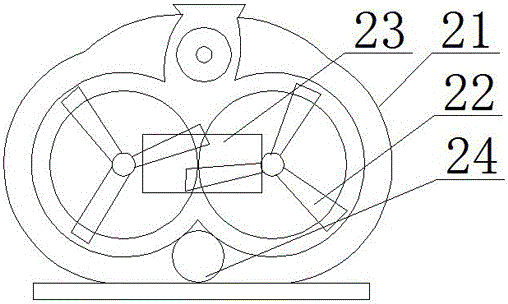

[0022] The crushing device 2 comprises an outer cover shell 21 with a double cylinder inner cavity, two groups of crushing assemblies 22 respectively installed in the double cylindrical inner cavity in the outer cover shell, and feed ports 23 and Outlet 24.

[0023] The body is also provided with a feeder belt 7, one end of the feeder belt 7 is connected to the feeding port 23 of the crushing device, the feeding port 23 is located in the middle of the outer cov...

Embodiment 2

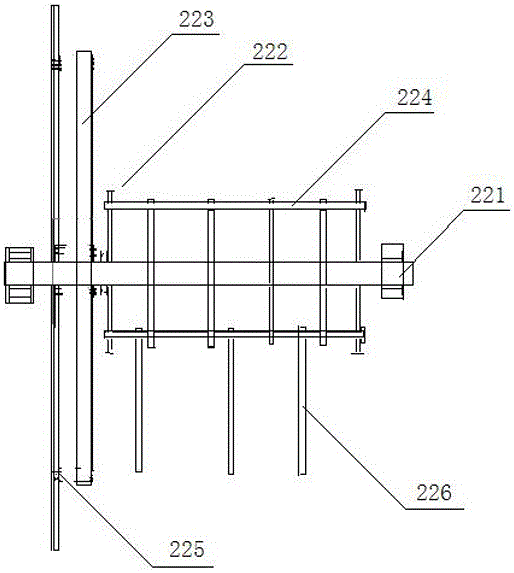

[0033] The difference from embodiment 1 is that the length of the kneading cutter 226 of the kneading and cutting knife set is the same as that of the fan knife 225 of the pulverizing knife set, and the two sets of kneading and cutting knives are arranged at intervals in the direction of their respective transmission shafts.

[0034] The fan knife of the crushing device cuts staggeredly at high speed while forming a wind wheel to push the crushed straw into the inner cavity of the double cylinder. The kneading and cutting knife group continues to process the straw until the straw is completely crushed, and then the crushed straw is heated and dried by the drying device. After the straw is dried, it is sent to the extrusion device to be extruded into block fuel or pellet feed; because of the traction head, it can work in the field, and the finished product can be stored in the finished product warehouse first, which is convenient for on-site processing of the straw. Adapting to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap