Flange sealing groove field repair process

A flange sealing and repairing technology, used in manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems of personal and property damage, RTJ groove leakage, and high maintenance costs, achieve high grinding efficiency, improve surface roughness, and facilitate on-site processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

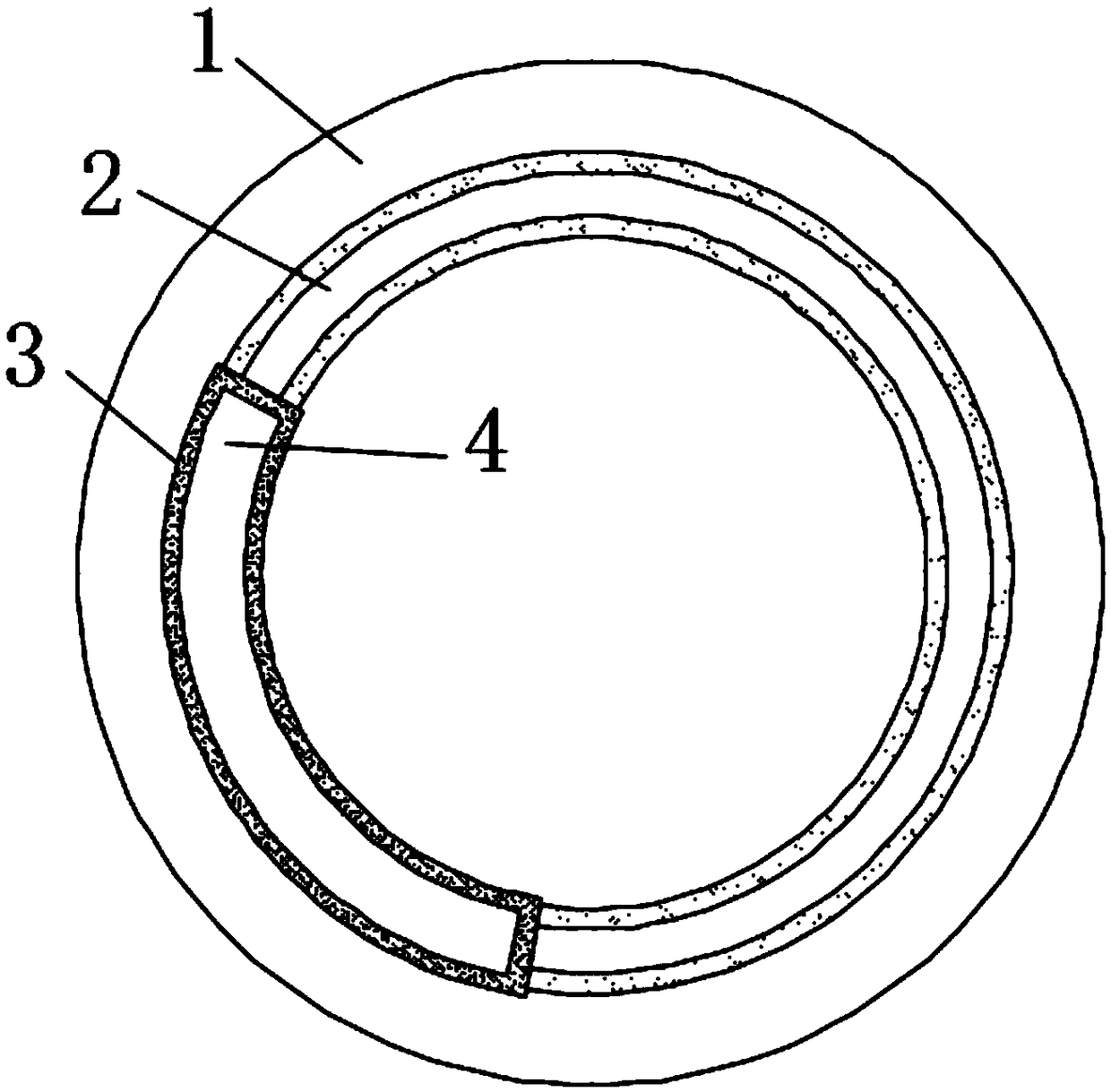

[0026] refer to Figure 1-2 , the present invention proposes a process for repairing flange sealing grooves on site, comprising the following steps:

[0027] Step 1: Pretreatment: Use a blower to blow out the dust and impurities in the flange sealing groove 2;

[0028] Step 2: Spread the grinding paper 3 flat: take the grinding paper 3, and spread the grinding paper 3 above the flange sealing groove 2 mentioned in step 1;

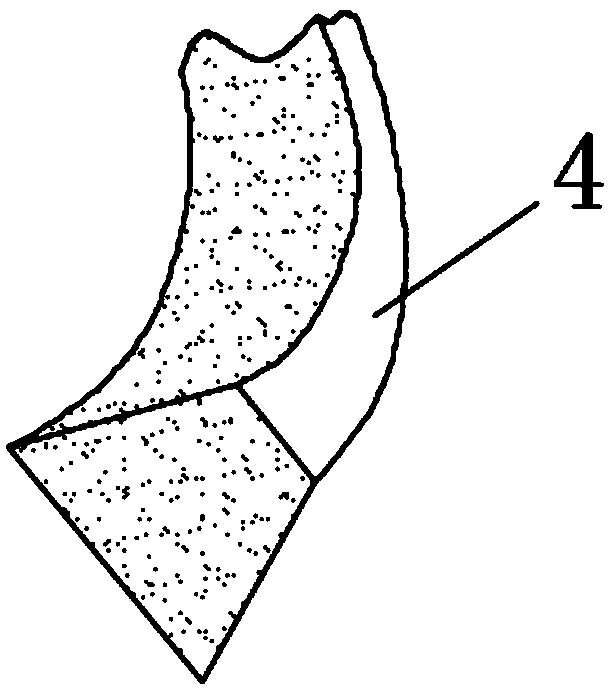

[0029] Step 3: Take the special tool 4: Take the special tool 4 for repairing the flange sealing groove 2;

[0030] Step 4: Pre-install tools: place the special tool 4 mentioned in step 3 on the grinding paper 3 laid in step 2, press the special...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap