Temperature control system for bearing block of compressor

A temperature control system, compressor bearing technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as poor lubrication, poor oil film cooling, and bearing stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

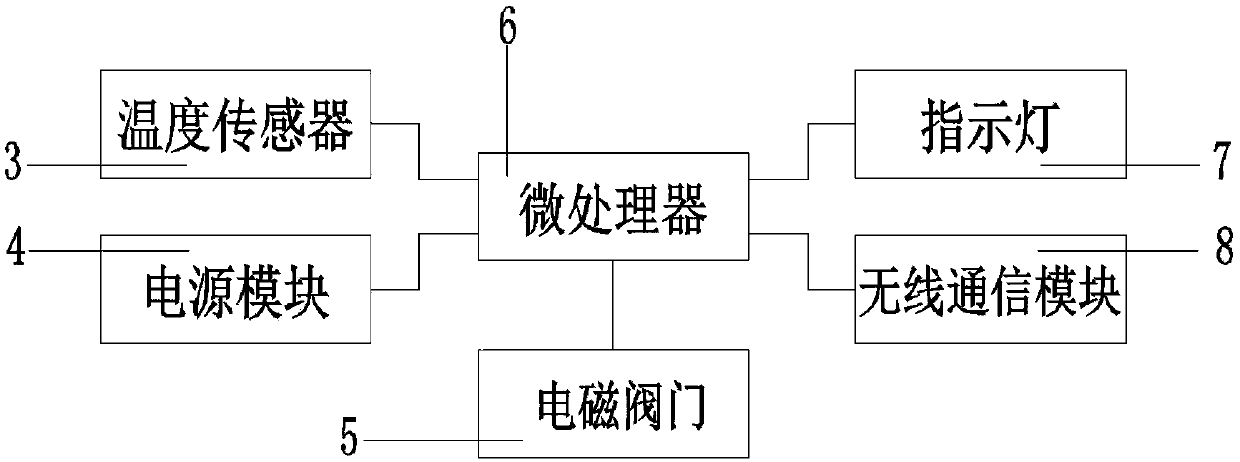

[0019] like figure 1 As shown, a compressor bearing seat temperature control system includes a microprocessor 6, a temperature sensor 3 and a power module 4, the temperature sensor 3 and the power module 4 are connected to the microprocessor 6, and the microprocessor 6 Connect to the electromagnetic valve 5, the indicator light 7 and the wireless communication module 8.

[0020] Preferably, the temperature sensor 3 , the power module 4 , the microprocessor 6 and the wireless communication module 8 are all installed inside the first cavity 9 .

[0021] Preferably, the temperature sensor 3 is DS18B20.

[0022] Preferably, the indicator light 7 is an LED light.

[0023] Preferably, the wireless communication module 8 is a Bluetooth communication module.

Embodiment 2

[0025] A compressor bearing seat temperature control system, including a microprocessor 6, a temperature sensor 3 and a power module 4, the temperature sensor 3 and the power module 4 are connected to the microprocessor 6, and the microprocessor 6 is connected to the electromagnetic On the valve 5, the indicator light 7 and the wireless communication module 8.

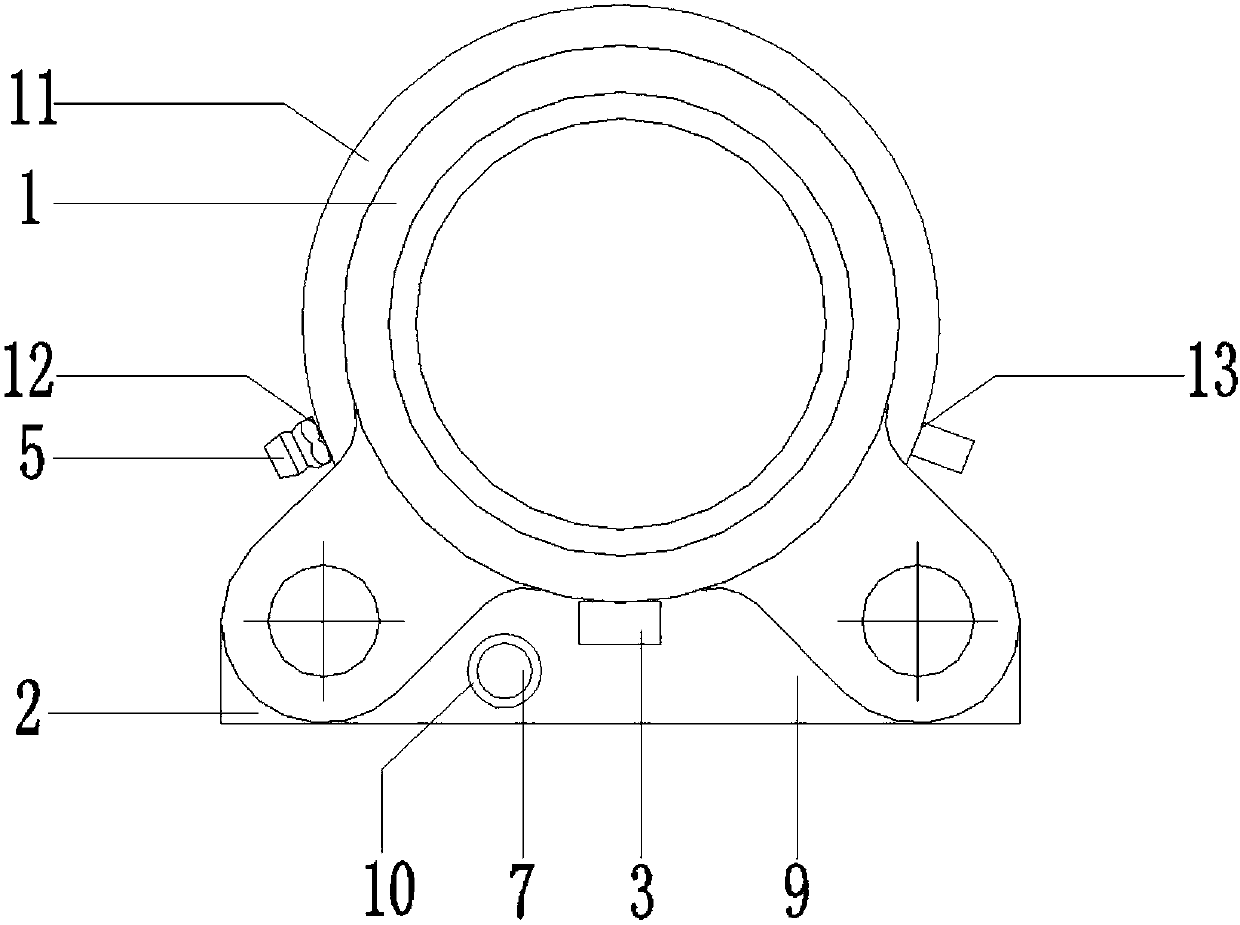

[0026] like figure 2 As shown, preferably, the temperature sensor 3 is installed in the base 2 close to the bearing outer ring 1, the base 2 also has a hole 10, and the indicator light 7 is embedded in the hole 10; the bearing outer The ring 1 is also provided with a second cavity 11, the second cavity 11 is provided with an oil outlet 12 and an oil inlet 13, and the oil inlet 13 is connected to the oil tank through the electromagnetic valve 5.

[0027] Preferably, the temperature sensor 3 , the power module 4 , the microprocessor 6 and the wireless communication module 8 are all installed inside the first cavity 9 ....

Embodiment 3

[0032] A compressor bearing seat temperature control system, including a microprocessor 6, a temperature sensor 3 and a power module 4, the temperature sensor 3 and the power module 4 are connected to the microprocessor 6, and the microprocessor 6 is connected to the electromagnetic On the valve 5, the indicator light 7 and the wireless communication module 8.

[0033] Preferably, the temperature sensor 3 is installed in the base 2 close to the bearing outer ring 1, the base 2 is also provided with a hole 10, and the indicator light 7 is embedded in the hole 10; the bearing outer ring 1 is also A second cavity 11 is provided, and the second cavity 11 is provided with an oil outlet 12 and an oil inlet 13, and the oil inlet 13 is connected to the oil tank through the electromagnetic valve 5.

[0034] Preferably, the temperature sensor 3 , the power module 4 , the microprocessor 6 and the wireless communication module 8 are all installed inside the first cavity 9 .

[0035] Pref...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap