Precision casting method of casting products based on vacuum molding equipment

A vacuum molding and casting technology, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of affecting production efficiency and the inability to quickly cool down sand particles, and achieve value improvement, shorten sand recovery time sequence, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

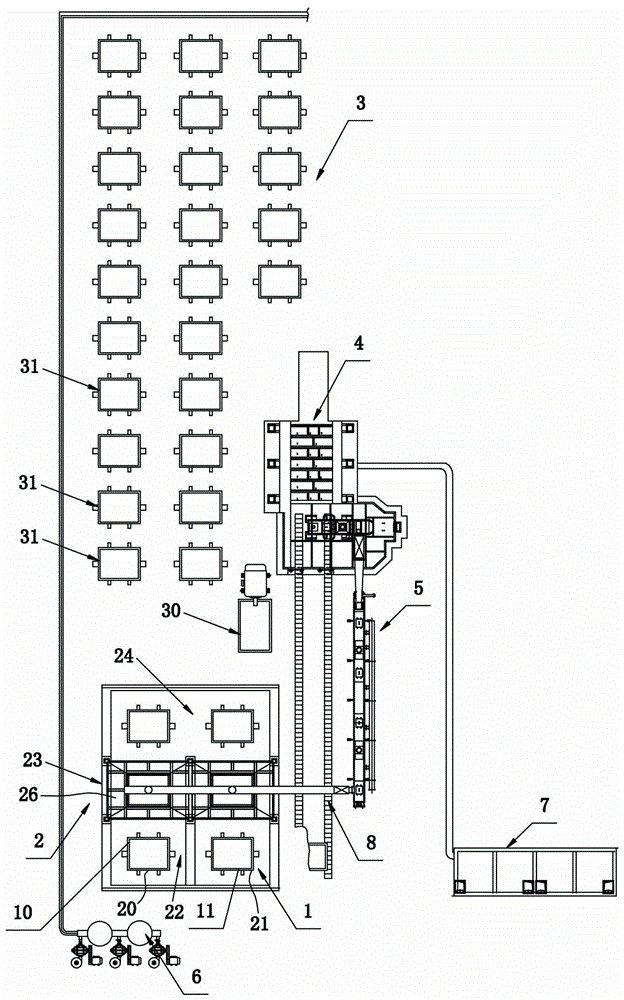

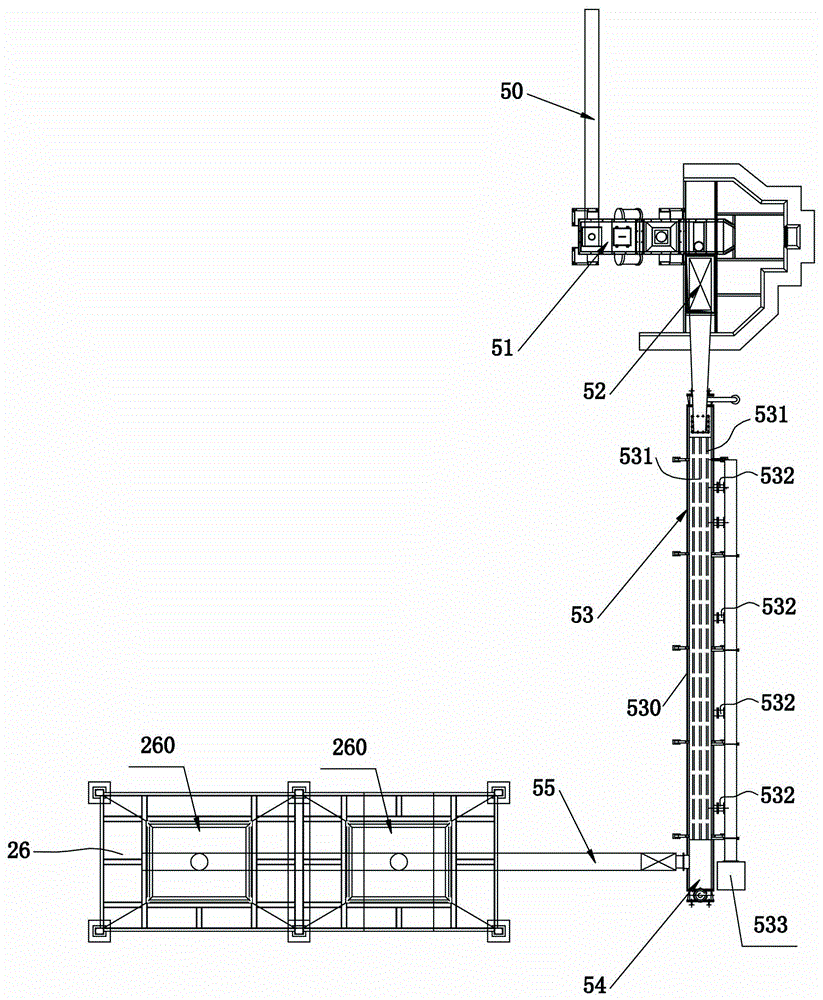

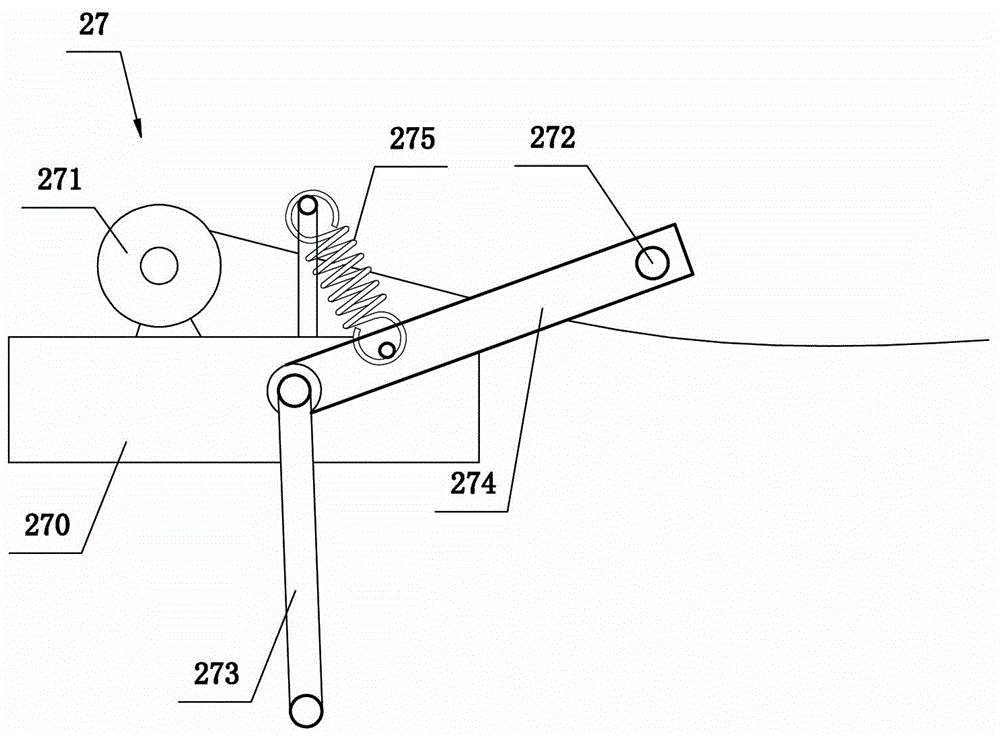

[0046] refer to Figure 1-Figure 10 . A vacuum molding production line with recyclable sand grains, comprising a casting mold frame mechanism 1, a vacuum molding mechanism 2 for filling sand grains in the casting mold frame mechanism 1 and covering both sides of the sand grains, The casting mold frame mechanism 1 pours the casting mechanism 3 of the molten metal, the sand grain casting separation mechanism 4, the sand grain recovery mechanism 5, the electric hoist device (not shown) used to carry the casting mold frame mechanism 1 and cooperate with the The electric hoist device (not shown in the figure) is a walking crane, the inlet of the sand recovery mechanism 5 is connected to the sand casting separation mechanism 4, and the outlet is connected to the vacuum molding mechanism 2;

[0047] The casting mold frame mechanism 1 includes an upper mold fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com