Multi-station and multi-direction full-automatic screw machine capable of overturning and positioning workpiece

A screw machine and fully automatic technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as slow speed, low efficiency, and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

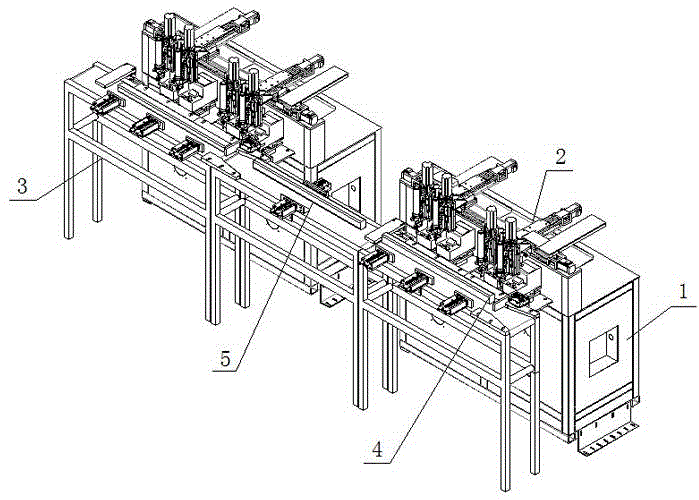

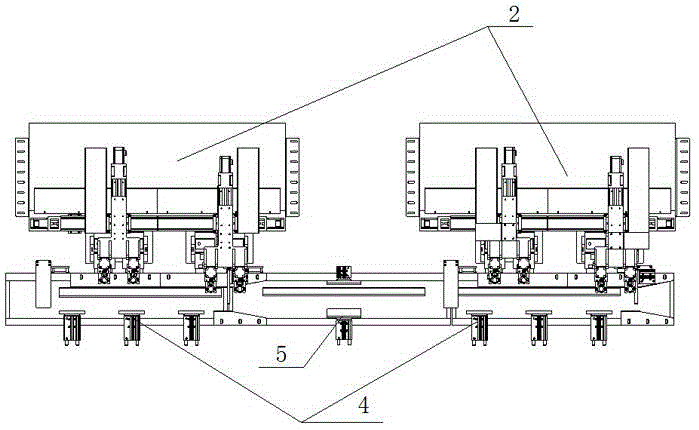

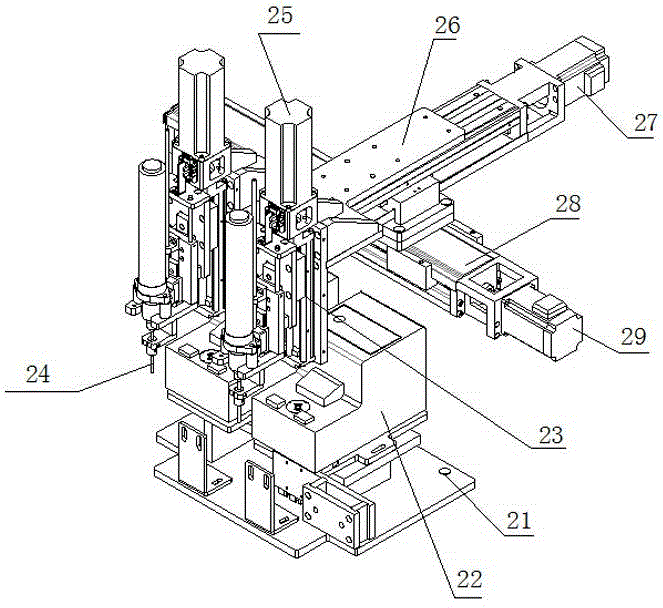

[0013] In this example, if Figure 1 to Figure 4 As shown, a multi-station and multi-direction automatic screw machine 2 with reversible positioning of workpieces of the present invention includes a workbench 1, an automatic screw machine 2 arranged on the workbench 1, and an automatic screw machine 2 arranged in front of the workbench 1. Support 3, and be arranged on support 3, the positioning mechanism 4 in front of automatic screw machine 2, and be arranged on support 3, the turnover mechanism 5 between two positioning mechanisms 4; Described automatic screw machine 2 is provided with more than one, The automatic screw machine 2 includes a base 21 arranged on the workbench 1, a screw feeder 22 arranged on the base 21, and a Z-axis moving assembly 23 arranged on the screw feeder 22, and installed on the The electric batch 24 or soldering iron (not shown) in front of the Z-axis moving assembly 23, and the Z-axis motor 25 arranged on the Z-axis moving assembly 23, and the Y-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com