Large-scale glass fiber reinforced plastic tank and forming die, manufacturing equipment and manufacturing method thereof

A technology for glass fiber reinforced plastic tanks and forming molds, which is applied in the field of manufacturing, large-scale glass steel tanks and their forming molds, and manufacturing equipment. It can solve the problems of immobility, poor sealing performance, and complicated molding processes, so as to avoid extrusion deformation or damage, Convenient and quick take out, to ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

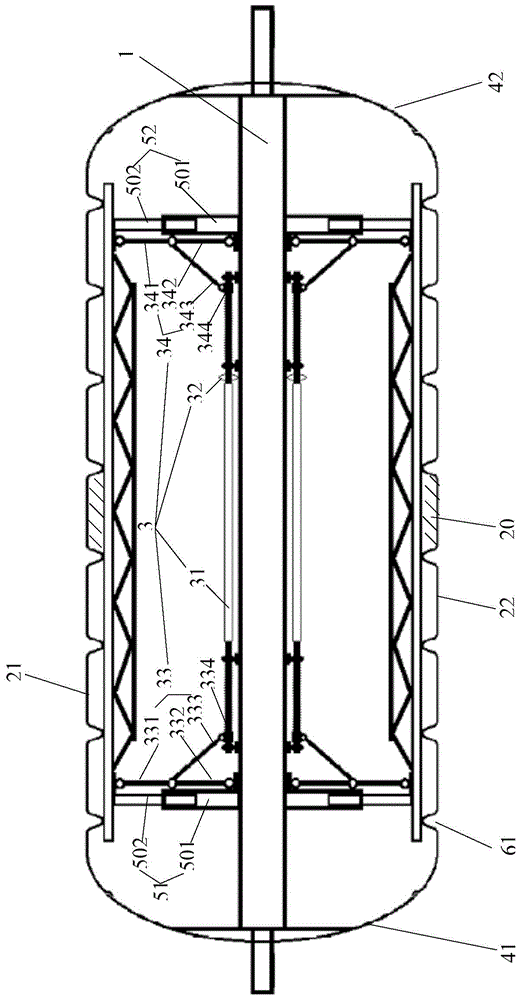

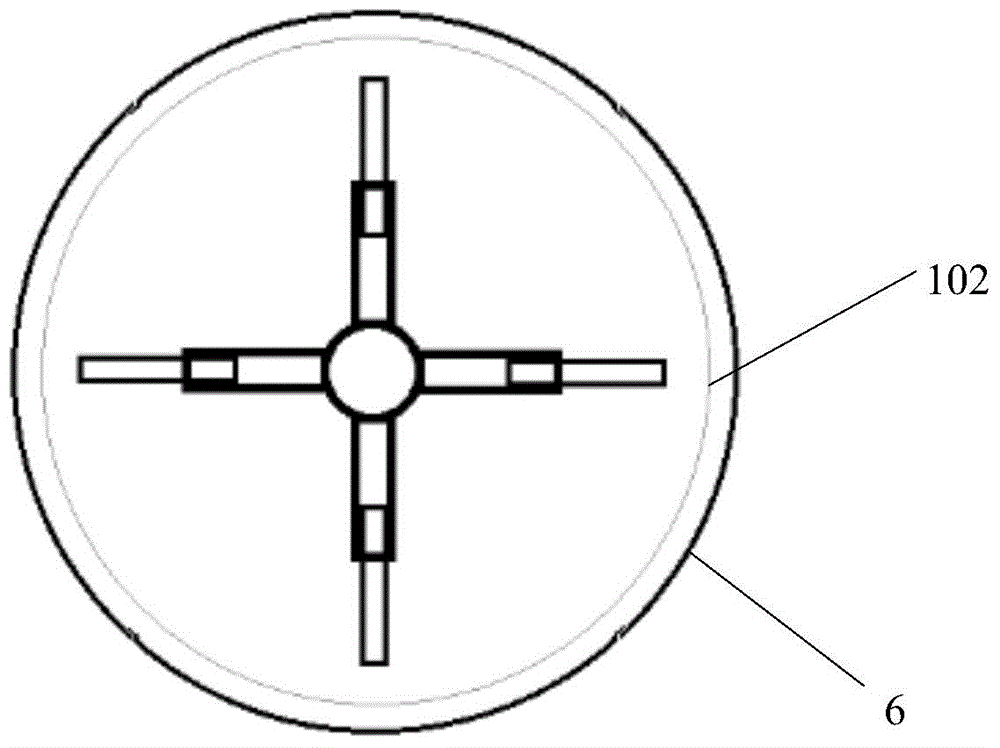

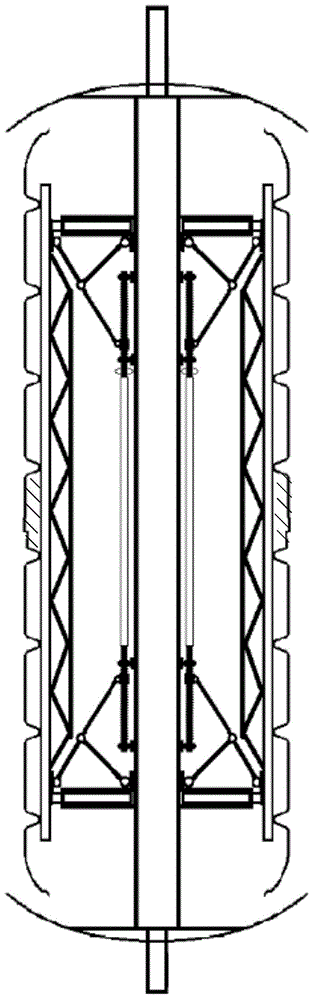

[0029] Such as Figure 1-Figure 4As shown, the large-scale FRP tank body forming mold of the embodiment of the present invention includes a main shaft 1 , a movable template, a cover template and a traction mechanism 3 . There are at least three moving templates, which are respectively arranged around the main shaft 1; usually there are two capping templates, namely, capping templates 41, 42, and the capping templates 41, 42 can be arc-shaped such as spherical, and of course other shapes can also be used. , the capping templates 41, 42 are respectively installed at both ends of the main shaft 1; the number of traction mechanisms 3 matches the number of movable templates, and each tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com