Embossing or calendering device

A technology of light device and pressing device, which is applied in the field of embossing or embossing, and can solve problems such as difficult machining accuracy and long axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiment:

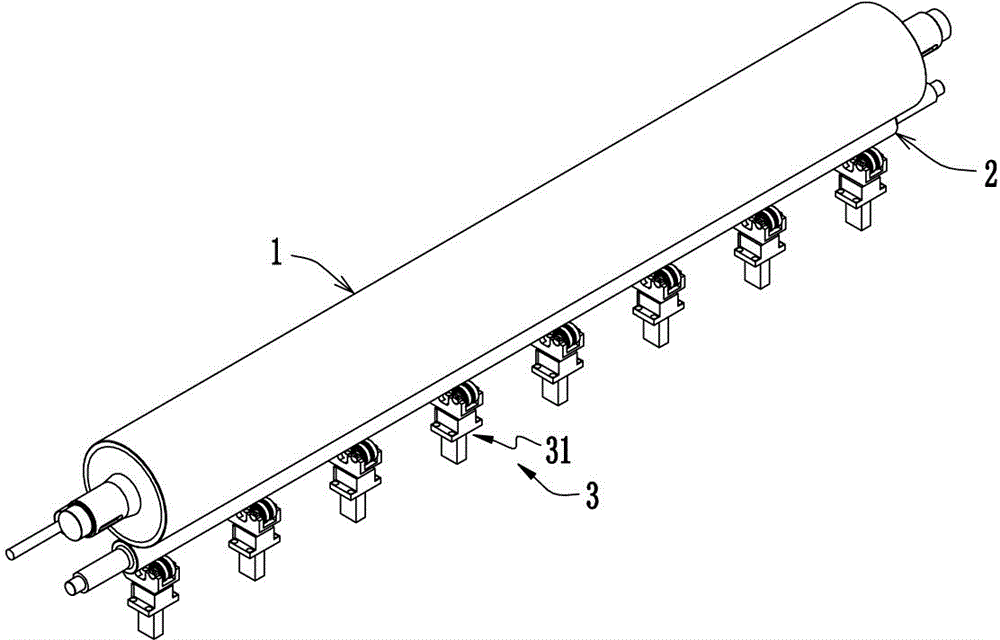

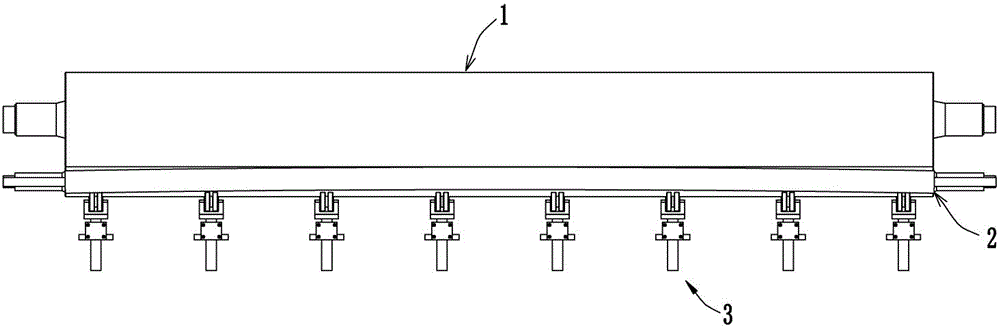

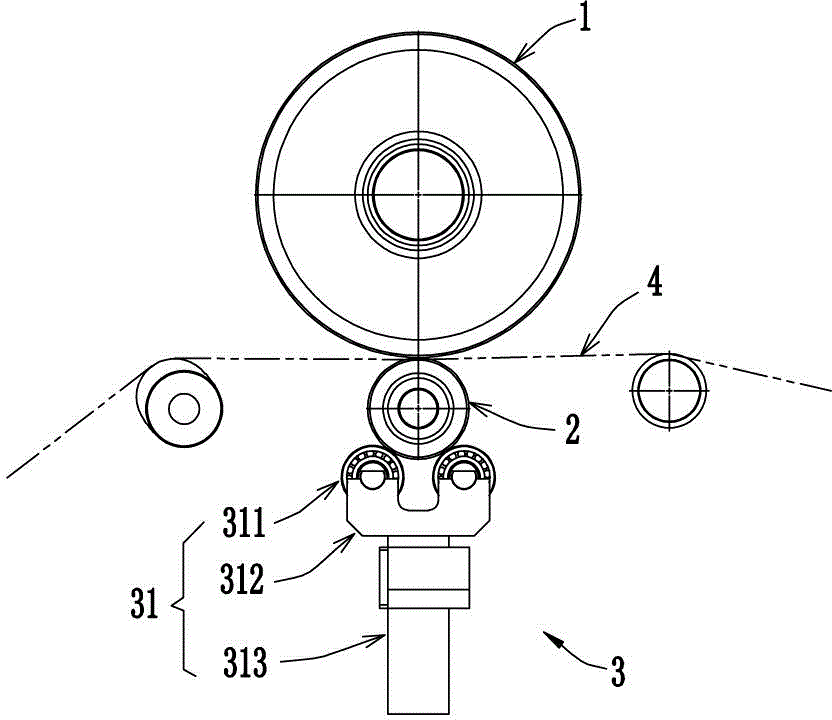

[0013] See attached figure 1 to attach image 3 Shown, a kind of embossing or embossing device described in this embodiment. The embossing or calendering device includes an embossing or calendering roll 1 (when performing embossing operations, the roll is a roll with a preset pattern or texture on the roll surface; when performing calendering operations, the roll is a roll with a roll surface smooth bachelor.), at least one smooth roll 2 that cooperates with the embossing or calendering roll 1 for embossing, and a pressing device 3 for driving the above-mentioned smooth roll 2 to closely adhere to the embossing or calendering roll 1, Among them, in order to ensure that the smooth roll 2 is under the pressure of the top pressure device 3, the smooth roll 2 can be deformed so as to fit the embossing or calender roll 1, and the smooth roll 2 is preferably elongated. In terms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com