Electro-hydraulic proportional solenoid valve

An electro-hydraulic proportional, solenoid valve technology, applied in the direction of fluid steering mechanism, can solve the problems of reducing high-speed driving safety, reducing power assist, steering wheel oversteering, etc., to improve driving safety, improve handling stability, and reduce valve size. The effect of mouth opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

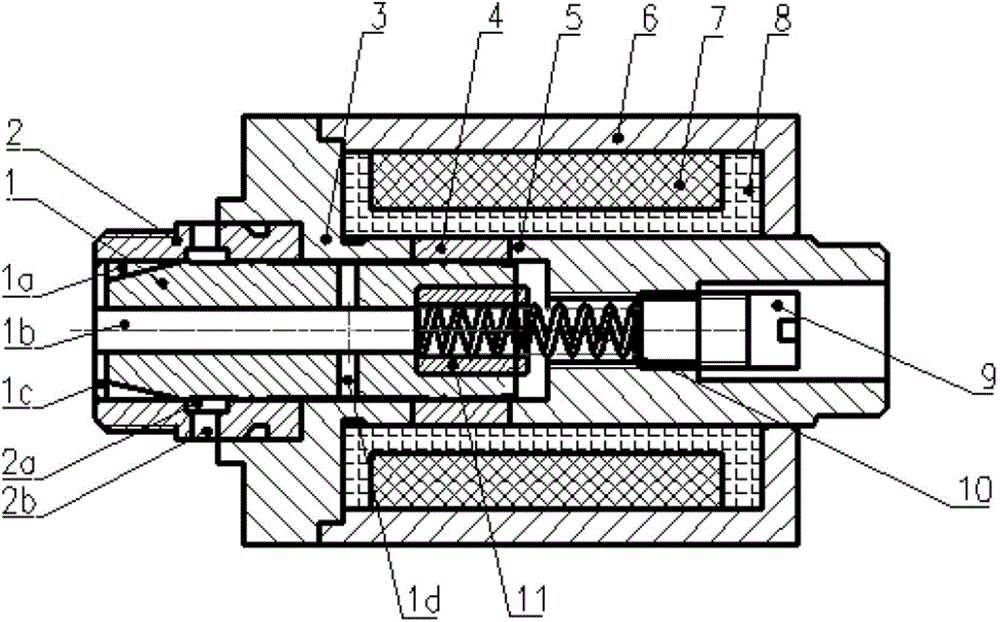

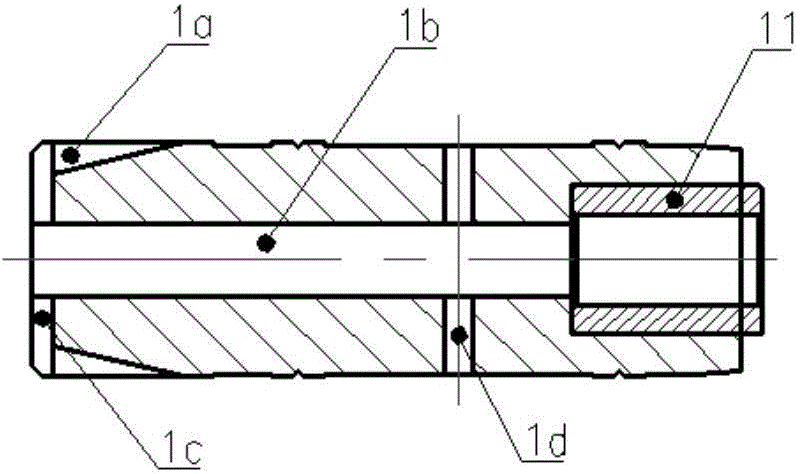

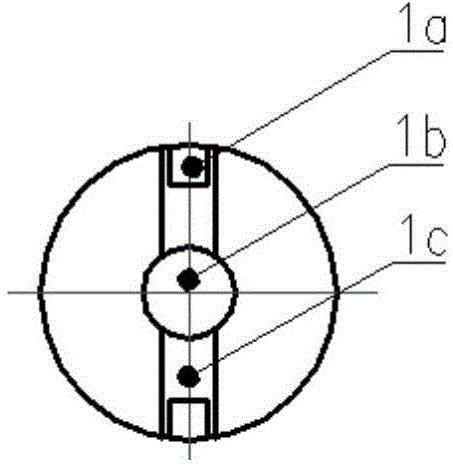

[0030] Such as figure 1 As shown, the electro-hydraulic proportional solenoid valve of the present invention includes a valve core 1 , an oil outlet valve sleeve 2 , a guide sleeve 3 , a magnetic isolation ring 4 , a pole piece 5 , and a coil 7 . The magnetic isolation ring 4 is made of non-magnetic material, and the two ends of the magnetic isolation ring 4 are respectively welded with the guide sleeve 3 and the pole shoe 5 to form a sleeve. The oil outlet valve sleeve 2 is provided with at least one oil outlet hole 2b, and one end of the oil outlet valve sleeve 2 and the guide sleeve 3 adopt an interference fit. At least one oil inlet wedge-shaped groove 1a is provided on the end outer peripheral surface of one end of the valve core 1, a straight groove 1c communicatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com