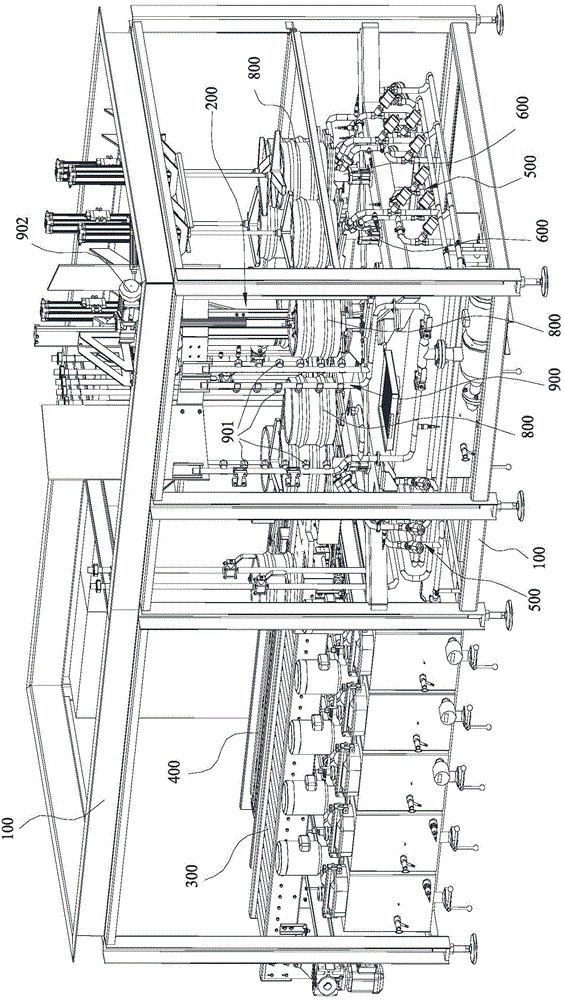

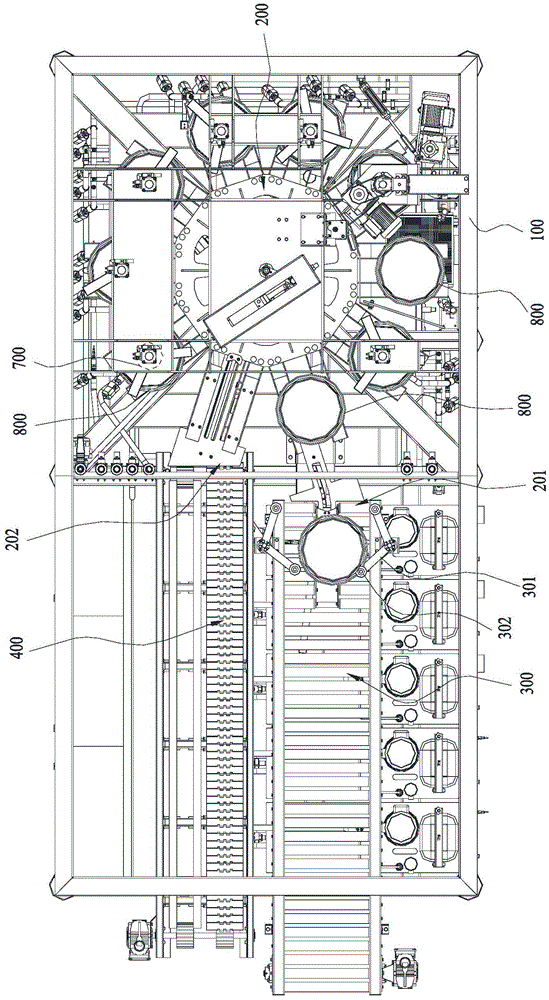

Full-automatic beer barrel washing and filling machine

A beer keg, fully automatic technology, applied in the field of automatic beer keg cleaning and filling machines, can solve the problem that beer keg is difficult to be automatically cleaned, disinfected, filled and produced, and achieves reliable switching, high efficiency, and is conducive to cleaning and production. The effect of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

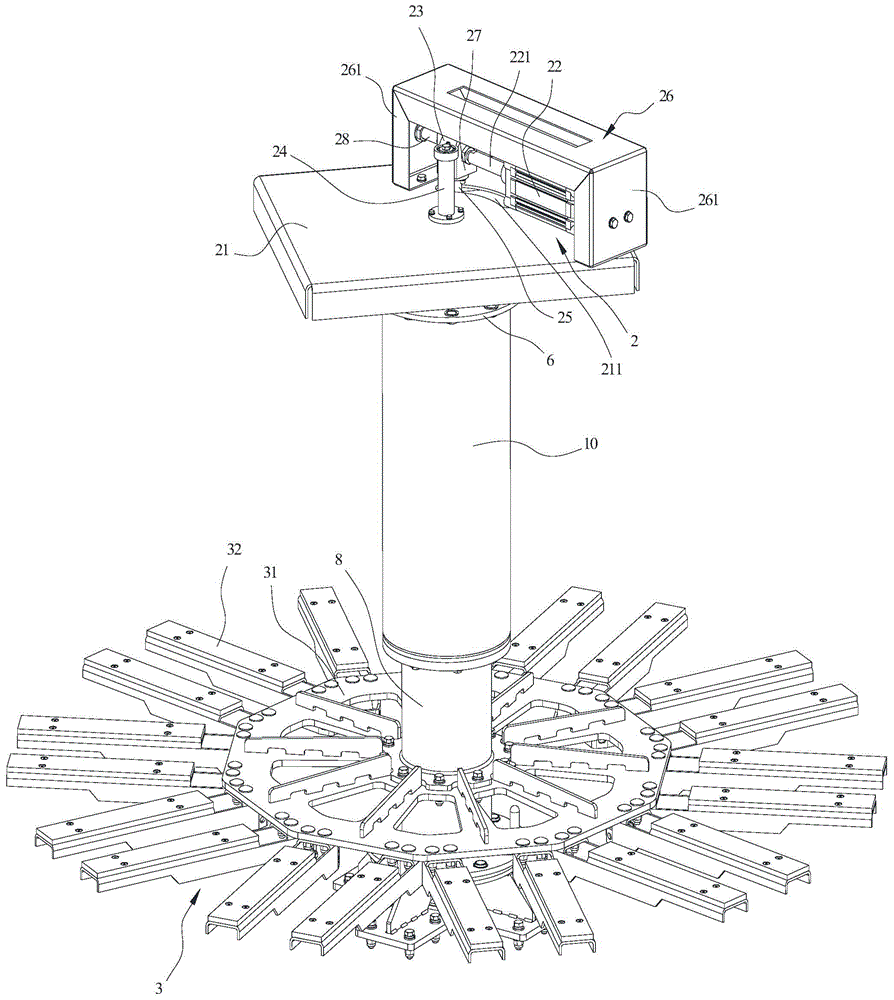

[0052] The driving mechanism 200 can be a disc-shaped rotating device driven by a motor, and its intermittent rotation function is controlled by the motor, and the following preferred implementation modes can also be adopted: the driving mechanism 200 of this example includes:

[0053] Connecting frame 1, rotating mechanism 2, turntable 3, first cylinder 4 and support column 5, wherein,

[0054] The rotating mechanism 2 is driven and connected with the connecting frame 1, and is used to drive the connecting frame 1 to rotate intermittently on the horizontal plane;

[0055] The turntable 3 is used to hold the beer keg 800, is connected with the connecting frame 1 and rotates synchronously with the connecting frame 1;

[0056] The first cylinder 4 is built into the connecting frame 1 and has a first piston rod 41 that expands and contracts in the vertical direction. The top of the connecting frame 1 is connected to the first piston rod 41 in a rotatable manner;

[0057] The sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com