Preparation method of tomato extract for fermented cigarettes

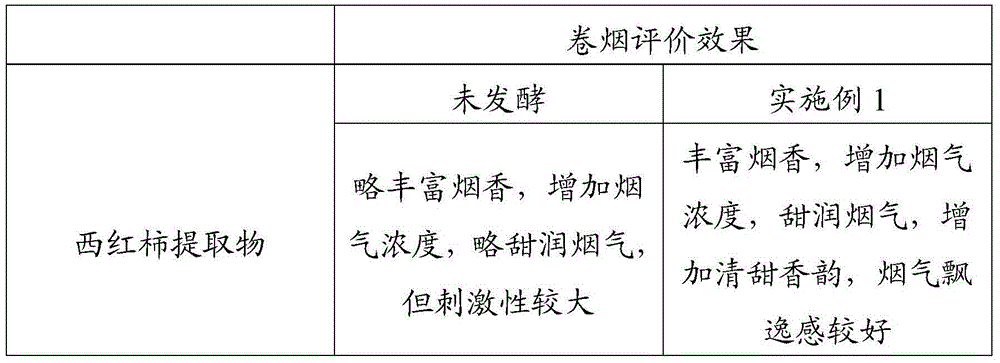

A tomato and extract technology, applied in the field of preparation of fermented tobacco tomato extract, to achieve the effects of increasing smoke concentration, reducing irritation, and obvious sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of fermented tobacco tomato extract comprises the following steps:

[0025] 1) Put the tomatoes into the fruit washing machine, wash them with tap water and squeeze them, and collect the crushed materials of the tomatoes;

[0026] 2) Heat and extract the crushed tomato material, stir while heating, and take it out 3 hours after boiling;

[0027] 3) Put the tomato extract obtained in step 2) to room temperature, add Hengshun rice vinegar with 1% by weight of the tomato extract, and seal it for natural fermentation for 10 days.

[0028] 4) After the fermentation is completed, according to the weight ratio of tomato fermented product: volume fraction of 95% ethanol = 1:1, add ethanol to the tomato fermented product while stirring, until it is evenly stirred for 1 hour after adding, and alcohol precipitation is carried out for 8 hour; and then filtered through the plate frame;

[0029] 5) Concentrate the filtrate obtained in step 4) to a relative de...

Embodiment 2

[0032] The preparation method of fermented tobacco tomato extract comprises the following steps:

[0033] 1) Put the tomatoes into the fruit washing machine, wash them with tap water and squeeze them, and collect the crushed materials of the tomatoes;

[0034] 2) heating and extracting the crushed tomato material, stirring while heating, until taking out 2 hours after boiling;

[0035] 3) Put the tomato extract obtained in step 2) to room temperature, add Hengshun rice vinegar with 1% by weight of the tomato extract, and seal it for natural fermentation for 15 days.

[0036] 4) After the fermentation is completed, according to the weight ratio of tomato fermented product:volume fraction of 95% ethanol = 1:3, add ethanol to the tomato fermented product while stirring, until it is evenly stirred for 1 hour after adding, and carry out alcohol precipitation 6 hour; and then filtered through the plate frame;

[0037] 5) Concentrate the filtrate obtained in step 4) to a relative d...

Embodiment 3

[0040] The preparation method of fermented tobacco tomato extract comprises the following steps:

[0041] 1) Put the tomatoes into the fruit washing machine, wash them with tap water and squeeze them, and collect the crushed materials of the tomatoes;

[0042] 2) heating and extracting the crushed tomato material, stirring while heating, and taking it out 4 hours after boiling;

[0043] 3) Put the tomato extract obtained in step 2) to room temperature, add Hengshun rice vinegar with 1% by weight of the tomato extract, and seal it for natural fermentation for 20 days.

[0044] 4) After the fermentation is complete, according to the weight ratio of tomato fermented product:volume fraction of 95% ethanol = 1:2, add ethanol to the tomato fermented product while stirring, until it is evenly stirred for 1 hour after adding, and carry out alcohol precipitation for 10 hour; and then filtered through the plate frame;

[0045] 5) Concentrating the filtrate obtained in step 4) to a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com