Preparation method of beet extract for cigarettes

A technology of sugar beet and extract, applied in the field of tobacco flavors and fragrances, can solve the problems of negative effect of cigarette residue, low pectin reduction rate, influence on sugar enrichment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get 500 grams of fresh beets, add 5 times the volume of clear water to wash twice, use a juicer to beat the cleaned beets, collect the slurry, and the slurry is beet juice; Hangzhou Zhongxiang Chemical Co., Ltd.), add 5 times the quality of distilled water and stir to dissolve, then filter with a 0.8-micron membrane filter, get the filtrate, and get the pectinase solution; add the gained pectinase solution to the beet juice. The consumption ratio of gelatinase solution and beet juice is 0.1 gram pectinase solution: 1 liter of beet juice, the pH value is 3, the temperature is to carry out enzyme treatment reaction 5 hours under 25 ℃, obtain enzyme treatment liquid; Adjust the pH value of the enzyme treatment solution to 8 at a stirring speed of 10 minutes, carry out isoelectric point sedimentation, stir for 10 minutes, and let stand for 12 hours to obtain the enzyme treatment settlement solution; coarsely filter the enzyme treatment settlement solution with gauze to filte...

Embodiment 2

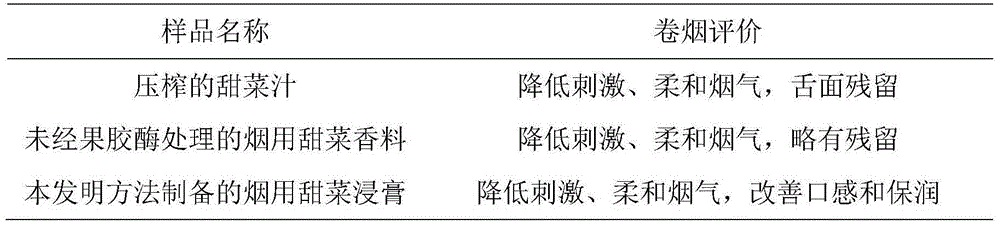

[0028] Carry out embodiment 1 repeatedly by the same steps as described, the difference is that the consumption ratio of used pectinase solution and beet juice is 1 gram of pectinase solution: 1 liter of beet juice; the pH value of enzyme treatment is 5, and the enzyme treatment temperature at 30°C, and the enzyme treatment time is 12 hours; when performing isoelectric point precipitation, the stirring speed is 8000 rpm, adjust the pH value of the enzyme treatment solution to 9, stir for 20 minutes, and stand for 18 hours; during the concentration process, concentrate The temperature is 70°C and the concentration pressure is 0.1 atmosphere. Concentrate to the relative density of sugar beet extract is 1.2570g / cm 3 . Compared with the pressed beet juice, the pectin concentration of the tobacco beet extract prepared by the method of the present invention is reduced by 58.13%, and compared with the tobacco beet flavor without pectinase treatment and other treatment steps, the pec...

Embodiment 3

[0030] Carry out embodiment 1 repeatedly by the same steps as described, the difference is that the consumption ratio of pectinase solution used and beet juice is 10 gram pectinase solution: 1 liter of beet juice; The pH value of enzyme treatment is 7, and the enzyme treatment temperature at 40°C, and the enzyme treatment time is 30 hours; when carrying out isoelectric point sedimentation, the stirring speed is 12000 rpm, adjust the pH value of the enzyme treatment solution to 10, stir for 30 minutes, and let it stand for 24 hours; during the concentration process, concentrate The temperature is 80°C and the concentration pressure is 0.2 atmospheres. Concentrate to a relative density of sugar beet extract of 1.350g / cm 3 . Compared with the pressed beet juice, the pectin concentration of the tobacco beet extract prepared by the method of the present invention is reduced by 78.40%, and compared with the tobacco beet flavor without pectinase treatment and other treatment steps, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com