Supporting method for carboniferous soft coal seam

A technology for soft coal seams and carboniferous systems, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems affecting tunneling, permanent support construction difficulties, difficult tunneling during construction, etc., to achieve cost saving, low cost, and improved tunneling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

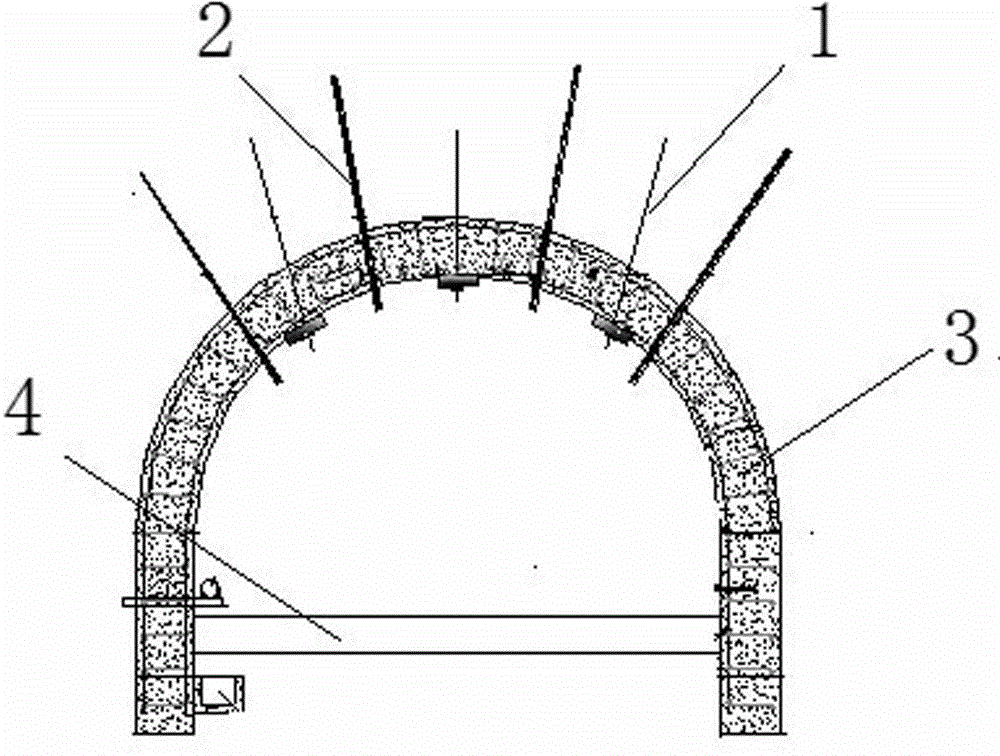

[0010] The support method of the Carboniferous soft coal seam is realized by the following steps: a. Use Φ22 full-length threaded steel anchor rod 1 to extend the anchor for temporary support; b. Use 24 Φ36×2m round steel as steel needle 2, penetrate into Fix the loose rock in the soft rock layer; c. The roof is drilled to release water, and the U29-shaped arched steel support 3 is built to introduce all the water into the drainage channel for comprehensive treatment; d. Concrete is integrally poured in the U29-shaped arched steel support 3, and the bottom is every 1m Construct a 2m-deep borehole to release the pressure on the bottom plate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com